Re - measurement of Appearance Dimensions

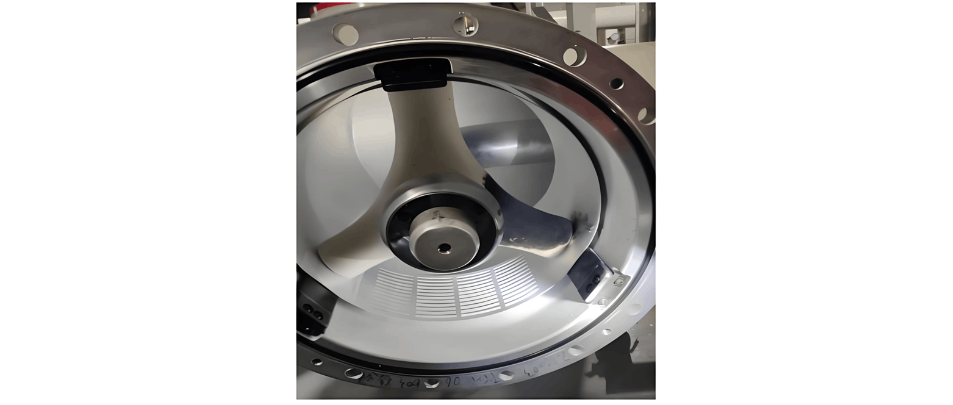

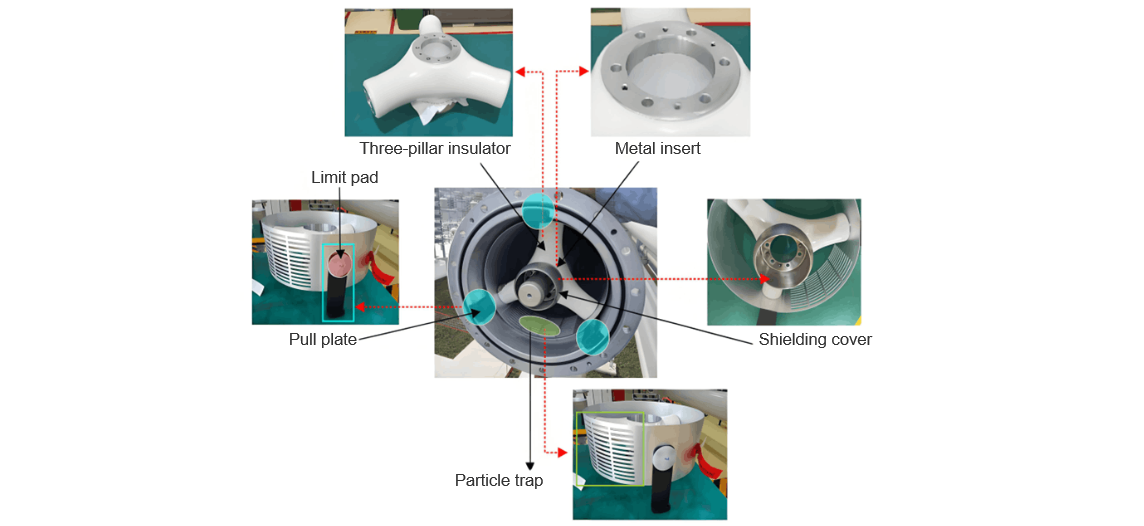

The faulty post insulator was returned to the factory for re - measurement of dimensions and appearance inspection. The faulty busbar post insulators were slightly wiped and the marks were polished. The surface of the post insulator was intact, and no visible cracks, bubbles, or other anomalies were found.

With reference to the drawings, multiple key dimensions of the post insulator, particle traps, shielding covers, pull plates, etc. were re - measured. This involved re - measuring multiple dimensions such as the center - to - center distance of the three legs of the post insulator, circumferential diameter, and angle. All dimensions were found to be qualified.

Dye Penetrant Inspection

Dye penetrant inspection was carried out on the post insulator. After cleaning and grinding, the inspection was conducted. The cleaning agent was sprayed onto the paper, and then the penetrant on the surface of the insulator was wiped clean. After careful inspection, no penetrant seepage was detected, and no anomalies were found in the dye penetrant inspection.

X - ray and Industrial CT Inspection

X - ray inspection was performed on the post insulator. The post insulator was rotated 360° for inspection, and no defects such as poor bonding, bubbles, or cracks were found.

Industrial CT inspection tests were carried out on the post insulator. The internal insulation material was generally uniform, with no air holes, cracks, impurities, or other defects found. There was no poor bonding between the low - voltage end insert and the epoxy resin, nor between the central cylinder and the epoxy resin.

Mechanical Performance Test

Mechanical performance tests were carried out on the post insulator, including a pressure test (12 kN, holding pressure for 30 min) and a torsion test (15 kN, holding pressure for 30 min). The surface of the post insulator was observed for any anomalies, cracks, or damage. No anomalies were found through the mechanical performance test.

Insulation Performance Test

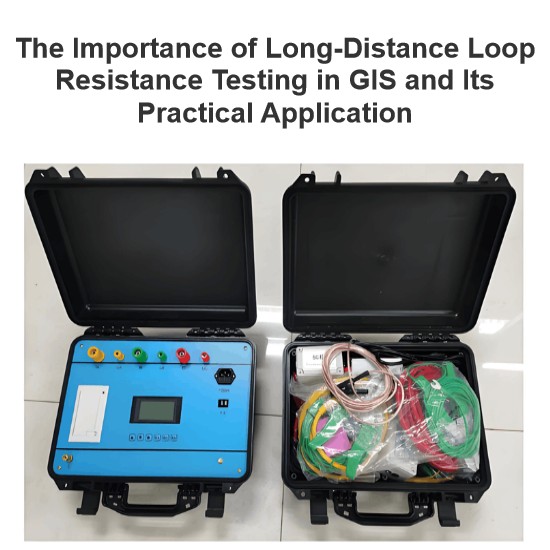

The post insulators were assembled into a busbar test state with new particle traps and the old particle traps (after grinding) returned from the site respectively, and filled with 0.5 MPa SF₆ gas inside.

First, the assessment was carried out according to the in - factory withstand voltage test method: power - frequency withstand voltage (740 kV for 1 min - 381 kV for 5 min), and lightning impulse (±1675 kV, 3 times each); then, the assessment was carried out according to the on - site withstand voltage test method: power - frequency withstand voltage (318 kV for 5 min - 550 kV for 3 min - 740 kV for 1 min - 381 kV for 45 min). All test results were normal, with no discharge or abnormal conditions.

Fault Reproduction Test

Based on the above analysis of the post insulator, it was determined that no fault problems were found in the design and manufacturing stages of the post insulator. It was preliminarily judged that foreign objects on the surface of the post insulator during the installation stage might have caused the flashover discharge. To further confirm the cause of the accident as analyzed, considering the possible hiding places of foreign objects and the situation of non - application of lubricating grease, reproduction tests under various working conditions were carried out, including: applying 1/3 lubricating grease on the post insulator (no discharge), applying 1/2 lubricating grease on the post insulator (no discharge), applying 2/3 lubricating grease on the post insulator (no discharge), applying 1/3 lubricating grease on the post insulator and blowing dust (dust onto the post insulator, no discharge), etc.

Based on the reproduction test results under the above - mentioned working conditions, it can be concluded that single - source lubricating grease contamination or metallic foreign objects are not likely to cause surface flashover breakdown of the insulator; for insulators that break down under power - frequency voltage, both the central insert and the ground - potential insert have obvious ablation marks; for insulators that break down under lightning impulse voltage, the central insert has ablation marks, which is similar to the phenomenon of the on - site fault.