Intelligent box-type substation based on 110 kV high-voltage GIS switchgear Design research

Dyson

05/23/2025

Selection and Setup of Distribution Equipment Based on GIS

Currently, commonly - used distribution equipment mainly includes outdoor open - type air - insulated switchgear, traditional indoor GIS, steel - structured indoor GIS, and outdoor hybrid GIS. This study aims at the substations in Indonesia to complete the setup of distribution equipment for intelligent prefabricated substations. Most of the substations in Indonesia are located in areas with complex terrains and low load densities. According to the current plan, the regional power grid development strategy is to utilize the existing 110 kV lines to build small - capacity substations. On this basis, the voltage levels will be gradually reduced to maximize investment efficiency, enhance equipment utilization, and downplay the role of 35 kV substations. The substations in the Indonesian power grid are large - scale, with high investment and equipment costs and long construction periods, necessitating further optimization in equipment selection and distribution equipment setup.

The outdoor hybrid GIS integrates circuit breakers and disconnectors, using conventional busbars. This arrangement can reduce the number of flanges and outdoor equipment, thereby increasing the land - use efficiency in the target area. Moreover, the hybrid GIS approach can lower the difficulty of installation and expansion, facilitating equipment installation and maintenance in mountainous and hilly regions.

Indonesia has a relatively humid climate with numerous high - temperature days, so intelligent control has stringent environmental requirements. In Indonesia, intelligent control cabinets generally require a relative humidity range of 5% - 95% and an ambient temperature range of - 5 - 55°C, with no frost formation allowed. To achieve cooling, dehumidification, and prevention of condensation for outdoor control cabinets, this study adopts the method of installing air - conditioners on the side of the cabinet doors.

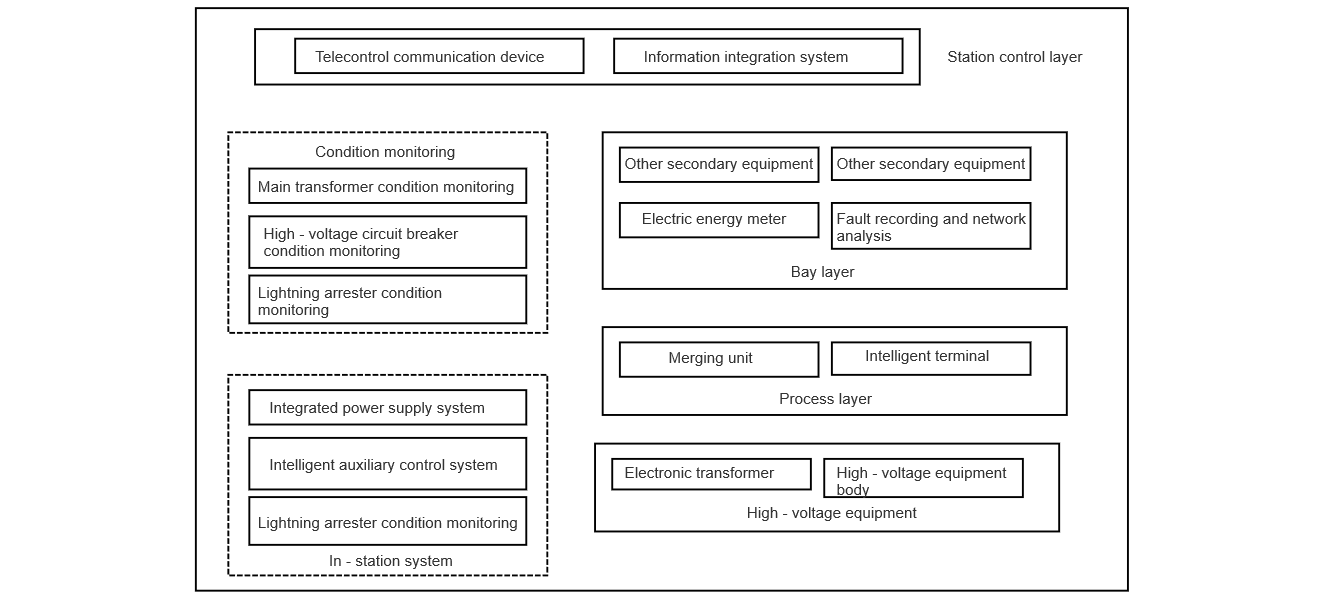

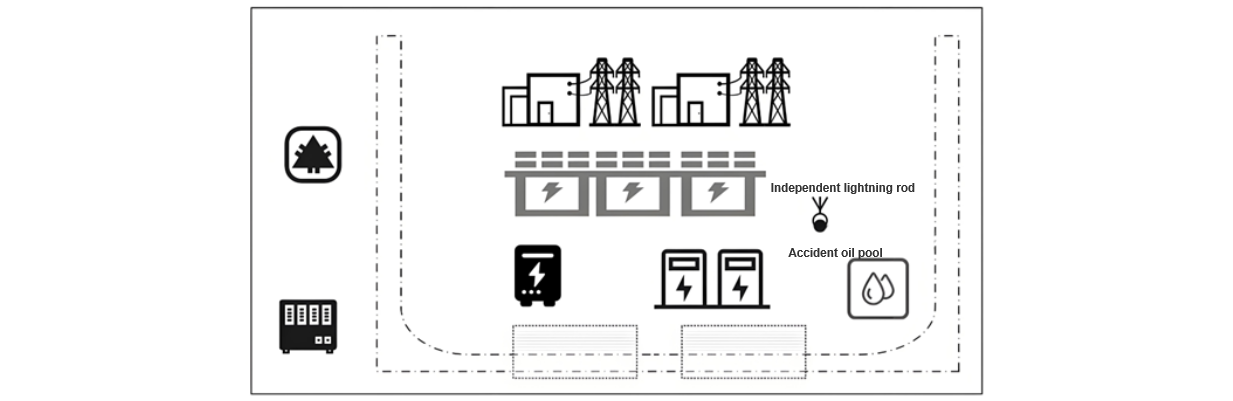

Regarding the main electrical wiring, it is essential to ensure its reliability, economic efficiency, operability, and safety during operation. For the single - busbar of 110 kV electrical wiring, sectional wiring or bridge - type wiring is commonly adopted. Bridge - type wiring has fewer circuit breakers and lower investment, but its reliability is inferior to that of sectional wiring, and the difficulty of subsequent modification and expansion is higher. Therefore, this study uses circuit breakers to section the busbar. With this sectional wiring method, when one section of the busbar fails, the remaining sections can still supply power normally, ensuring reliable service. The single - busbar sectional wiring is relatively simple, with fewer equipment components, and offers high reliability and operability. The structure of the improved intelligent substation is shown in Figure 1.

Transformers within the substation, as crucial equipment, play a vital role in state detection. Considering investment costs and application scenarios, the design scheme of this study employs an on - line dissolved gas monitoring device in oil and an on - line iron core grounding current detection device. The former, priced at approximately 200,000 RMB per set, is used to detect the internal insulation of the main transformer, while the latter is for real - time detection of the iron core grounding current. Both technologies are relatively mature and widely applied.

The intelligent main transformer integrates primary and secondary equipment, enabling it to perform state perception and operational state assessment. To facilitate daily maintenance and monitoring shifts and reduce maintenance workload, natural oil - circulation air - cooling is chosen as the cooling method for the main transformer.

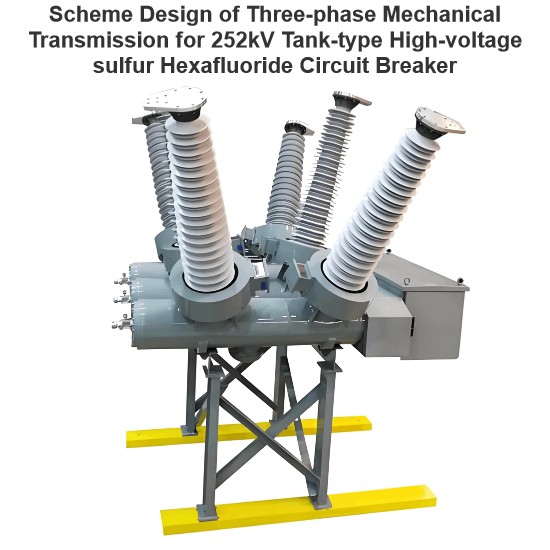

The hybrid GIS integrates circuit breakers, switches, and current transformers into a single entity, streamlining the reconstruction process by reducing the number of equipment. Moreover, outdoor hybrid GIS features a smaller number of equipment and flanges, offering higher reliability and corrosion resistance, which makes it perform well in the target area. The rated voltage of the hybrid GIS bay equipment is 126 kV, and the rated current is 2000 A. Each hybrid GIS bay equipment comprises sensors, intelligent control cabinets, and SF₆ gas state detection devices. These devices can detect the gas state and equipment operating status, enabling digital measurement, information interaction, and status inquiry functions for high - voltage switches.

Optimization of Distribution Equipment and General Layout

In the original intelligent substation design, the configuration of intelligent terminal cabinets and hybrid GIS control - gathering cabinets followed the arrangement of allocating two cabinets per bay. However, this approach results in numerous cable - crossing loops, which is unfavorable for daily maintenance. Therefore, the secondary circuits of intelligent terminals and hybrid GIS mechanisms can be integrated. By combining control panels, interlocking loops, anti - tripping loops, and non - in - phase loops into the intelligent terminal, an integrated design can be achieved.

The optimization of intelligent control cabinets mainly encompasses three aspects: (1) Simplifying the circuit by replacing hard - wiring logic with local terminal software logic; (2) Enabling bay - to - bay communication through intelligent terminals and substation event - oriented object technology; (3) Adopting an integrated design of intelligent terminals and circuit breaker control circuits to reduce redundant functions such as pressure interlocking loops. In addition to these circuit improvements, the layout of intelligent terminals within the original control - gathering cabinets is retained, and the connections between intelligent control - gathering cabinets and corresponding equipment are optimized.

The design scheme proposed in this study adopts the modular prefabricated cabin model. The layout of the substation should be based on the natural conditions and engineering requirements of the target area, and possess advantages such as safety, reliability, environmental friendliness, fire protection, and convenient operation and maintenance. In the target area, 110 kV distribution equipment and main transformers are arranged from north to south. To meet transportation requirements, a circular fire - fighting passage is set up within the substation, and on - site equipment installation utilizes a minimized layout. Through this layout, 18% of the land area can be saved. The general layout of the distribution equipment in the design scheme is shown in Figure 2.

In terms of optimization of distribution dimensions

The design scheme proposed in the research arranges hybrid GIS equipment in two rows, and the 110 kV distribution equipment adopts outdoor aluminum - magnesium alloy support tube busbars. The standard sectional bay layout typically features a linear arrangement of soft conduit busbars at both ends, which occupies a large amount of lateral space. Thanks to the integration of hybrid GIS equipment, its layout is more compact. The research sets the lateral dimension of the sectional bay at 8 m, which is 2 m shorter than before. The standard longitudinal length is 39 m. To optimize the longitudinal dimension, the proposed scheme uses integrated equipment, removes the incoming line structure, and modifies the busbar framework, thereby reducing the occupation of longitudinal space. Through these two improvements, the longitudinal dimension in the scheme is 25.2 m, 13.8 m shorter than the standard length, effectively reducing the space occupied by the equipment.

Performance and Cost Analysis of Intelligent Prefabricated Substations

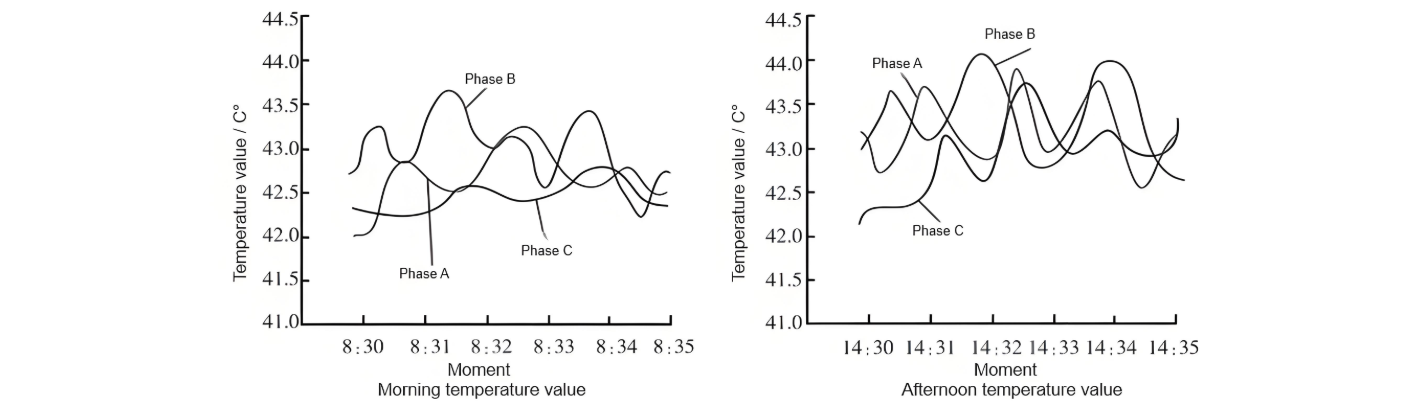

After the construction of the prefabricated substation is completed, relevant commissioning steps need to be carried out to ensure that the functions of each device can meet the design requirements and enable normal communication between the devices and software. The experiment records and analyzes data such as the current, voltage values, active power, transformer temperature, and power factor of each switch in the prefabricated substation to ensure the stable operation of the substation equipment. Among them, the transformer temperature values at different time periods are shown in Figure 3.

By observing Figure 3(a), it can be found that the temperature values of phase A, phase B, and phase C all remain in a relatively stable state. The temperature of phase B is the highest, reaching 43.6 °C from 8:31 to 8:32; the temperature of phase A varies between 42.0 - 43.2 °C; and the temperature of phase C remains around 42.5 °C. In Figure 3(b), the variation in the transformer temperature values collected in the afternoon is also relatively small. Due to environmental changes, the overall temperature values of phase A, phase B, and phase C are higher than the morning measurement values but still within the normal temperature range. At 14:32, the temperature value of phase B is 44.1 °C, and at this time, the temperature values of phase A and phase C are 42.9 °C and 42.6 °C respectively. Throughout the entire measurement period, the lowest temperature of phase C is 42.2 °C and the highest is 43.7 °C, while the temperature of phase A fluctuates within the range of 42.6 - 43.8 °C.

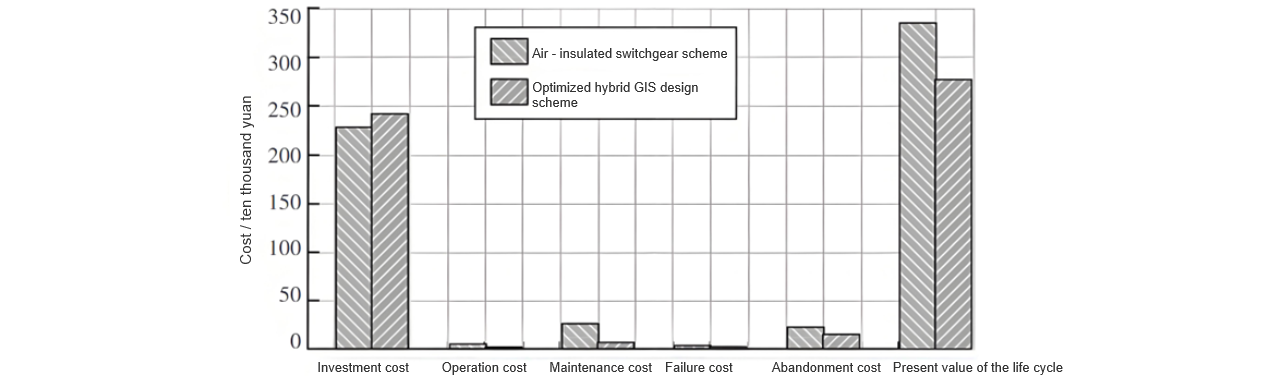

Analysis of the on - site test data shows that the data of the prefabricated substation all meet the design requirements and comply with relevant acceptance standards. In terms of economic utility, based on the life - cycle cost theory, the experiment analyzes and calculates the various costs of the 110 kV distribution equipment, and selects the air - insulated switchgear scheme for comparison. The comparison results are shown in Figure 4.

In Figure 4, the upfront investment cost for the optimized hybrid GIS design scheme is 2.413 million RMB, which is 0.133 million RMB higher than that of the air - insulated switchgear scheme. This is mainly because the equipment procurement cost of the hybrid GIS design scheme is higher than that of the air - insulated switchgear scheme, and the installation engineering cost is also slightly higher.

During the operation and maintenance phase, the required cost proportion is relatively small. Since the substation of the optimized hybrid GIS design scheme is an unmanned substation, only a small amount of regular manual inspections are needed, which reduces the daily operation and maintenance costs. Therefore, the operation and maintenance cost is much lower than that of the air - insulated switchgear scheme.

The annual failure probability of the optimized hybrid GIS design scheme has been significantly reduced, resulting in a notable decrease in maintenance costs. Moreover, its demolition cost is only 89% of that of the air - insulated switchgear scheme. Considering all factors, the present value of the life - cycle cost of the optimized hybrid GIS design scheme is 0.549 million RMB lower than that of the air - insulated switchgear scheme. Additionally, the 110 kV GIS intelligent substation scheme is superior to the conventional air - insulated switchgear scheme.

Conclusion

In order to conserve urban land resources, shorten the construction period, and enhance the economic efficiency and reliability of prefabricated substations, this research proposes an outdoor hybrid GIS design scheme that integrates circuit breakers and disconnectors. By optimizing the circuit and adopting single - busbar sectional wiring, and optimizing the overall layout, the number of failures is reduced and the maintenance cost is lowered.

The test results show that during the collection of transformer temperature, the temperature values of phase A, phase B, and phase C remain relatively stable. In the morning, the temperature of phase A varies between 42.0 - 43.2 °C, while that of phase C stays around 42.5 °C. In the afternoon, the temperature of phase C ranges from a minimum of 42.2 °C to a maximum of 43.7 °C, and the temperature of phase A fluctuates between 42.6 °C and 43.8 °C. The data of the prefabricated substation meet the design requirements and comply with relevant acceptance standards.

In the life - cycle cost analysis, although the upfront investment cost of the optimized hybrid GIS design scheme is 2.413 million RMB, 0.133 million RMB higher than that of the air - insulated switchgear scheme, the optimized hybrid GIS design scheme requires only a small amount of regular manual inspections. This reduces the daily operation and maintenance costs, making the operation and maintenance cost much lower than that of the air - insulated switchgear scheme, and significantly reducing the maintenance cost as well. Calculations show that the present value of the life - cycle cost of the optimized hybrid GIS design scheme is 0.549 million RMB lower than that of the air - insulated switchgear scheme, demonstrating that the optimized 110 kV GIS intelligent substation scheme is superior to the conventional air - insulated switchgear scheme.

However, this research only analyzes and optimizes the primary substation design. In the future, a more comprehensive intelligent design for secondary substations needs to be carried out by comprehensively considering communication and land construction.

Focused on the design of electrical equipment, proficient in electrical principles and relevant specifications, and skilled in using design software. From intelligent substations to various types of electrical equipment, I am adept at optimizing design solutions, integrating new technologies. With practical experience and collaborative management capabilities, I deliver outstanding electrical design achievements.