| Brand | ROCKWILL |

| Model NO. | RCW S21.9M MV outdoor vacuum recloser |

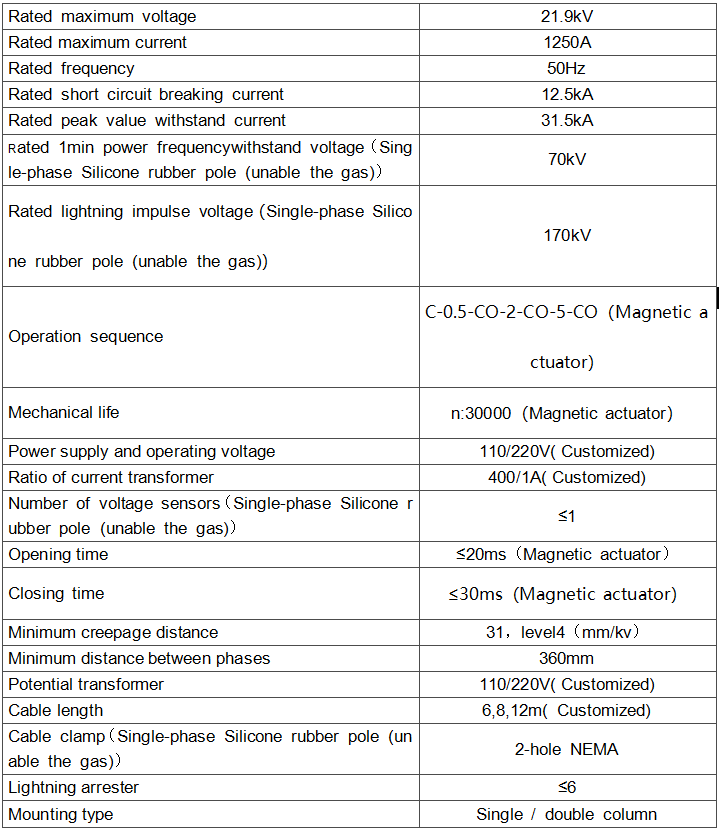

| Rated voltage | 21.9kV |

| Rated normal current | 1250A |

| Rated short circuit breaking current | 25kA |

| Power frequency withstand voltage | 70kV/min |

| Rated lightning impulse voltage | 170kV |

| manual closing | Yes |

| Series | RCW |

Description:

The RCW series automatic circuit reclosers can use on overhead distribution lines as well as distribution substation applications for all voltage classes 11kV up to 38kV at 50/60Hz power system. and it’s rated current can reach 1250A.The RCW series automatic circuit reclosers integrates the functions of control, protection, measurement, communication, fault detection, on-line monitoring of closing or opening.The RCW series vacuum recloser is mainly combined with integration terminal, current transformer, permanent magnetic actuator and it’srecloser controller.

Features:

Optional grades available in rated current range.

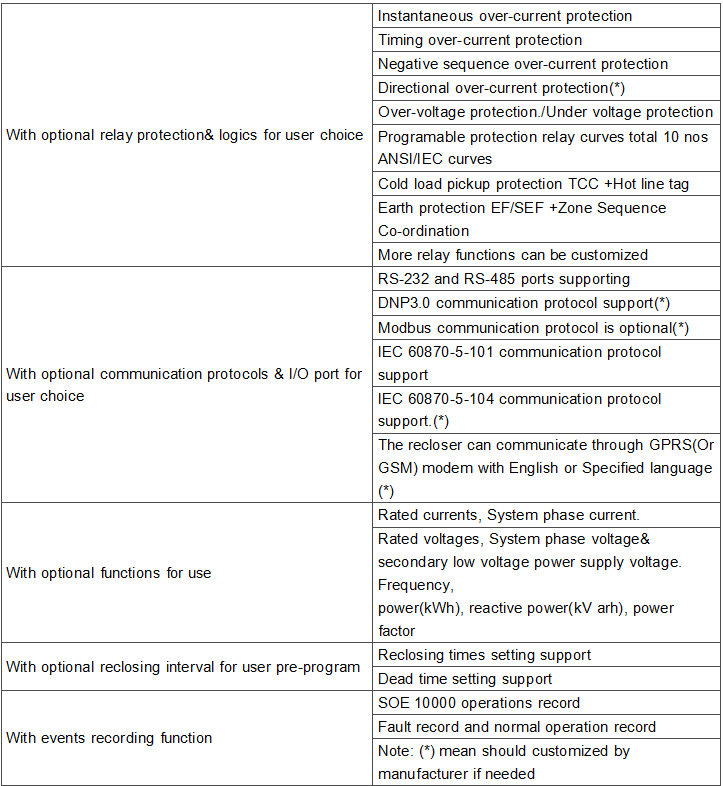

With optional relay protection and logic for user selection.

With optional communication protocols and I/O ports for users to choose.

PC software for controller testing, setup, programming, updates.

Parameters:

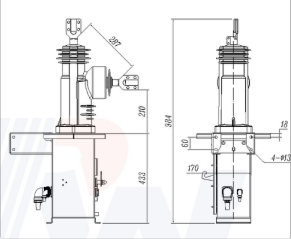

External dimensions

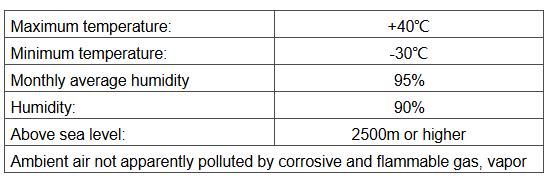

Environmental requirement

Product show

What are the insulation faults of outdoor vacuum reclosers and their solutions?

Clean Insulators: For insulators that experience flashover due to surface contamination, regular cleaning is necessary. Specialized insulator cleaning tools, such as insulator cleaning brushes or high-pressure water guns, can be used. After cleaning, anti-flashover coatings can be sprayed on the insulator surfaces to enhance their contamination resistance.

Replace Insulators: If insulators show a decrease in insulation strength due to lightning strikes or other reasons, and exhibit obvious cracks or damage, they should be replaced promptly. When replacing insulators, choose ones that meet the voltage and mechanical strength requirements of the equipment.

Test Insulation Performance: Use insulation resistance testers, dielectric loss testers, and other equipment to regularly test the insulation performance of insulating materials. When a decline in insulation performance is detected, analyze the causes of aging.

Replace Insulation Components: If insulation aging is severe, such as when partial discharge phenomena are observed, aged insulation components (e.g., insulating bushings, insulating supports) should be replaced promptly. Additionally, improve the operating environment of the equipment, such as by enhancing ventilation and reducing humidity, to slow down the aging process of the insulation.

Clean Insulators: For insulators that experience flashover due to surface contamination, regular cleaning is necessary. Specialized insulator cleaning tools, such as insulator cleaning brushes or high-pressure water guns, can be used. After cleaning, anti-flashover coatings can be sprayed on the insulator surfaces to enhance their contamination resistance.

Replace Insulators: If insulators show a decrease in insulation strength due to lightning strikes or other reasons, and exhibit obvious cracks or damage, they should be replaced promptly. When replacing insulators, choose ones that meet the voltage and mechanical strength requirements of the equipment.

Test Insulation Performance: Use insulation resistance testers, dielectric loss testers, and other equipment to regularly test the insulation performance of insulating materials. When a decline in insulation performance is detected, analyze the causes of aging.

Replace Insulation Components: If insulation aging is severe, such as when partial discharge phenomena are observed, aged insulation components (e.g., insulating bushings, insulating supports) should be replaced promptly. Additionally, improve the operating environment of the equipment, such as by enhancing ventilation and reducing humidity, to slow down the aging process of the insulation.