1.14 Design of Ring-Shaped Grounding Busbar

The ring-shaped grounding busbar, made of hot-dip galvanized flat steel, is openly laid along the walls of the high-voltage room. It connects primary equipment grounding, protective grounding, and maintenance grounding, with sufficient manual grounding terminals to meet "five-prevention" requirements and ensure safe maintenance grounding. Four soft copper wires 引出 (led out) from the busbar pass through the cabin floor to form reliable connections with the main grounding grid, establishing a global grounding system.

2 Analysis of Key Technologies

Prefabricated cabin-type high-voltage rooms achieve rapid substation construction, environmental optimization, and safe operation through three core technologies, supporting stable 10kV switchgear operation:

2.1 Intensive Layout of Cable Layer

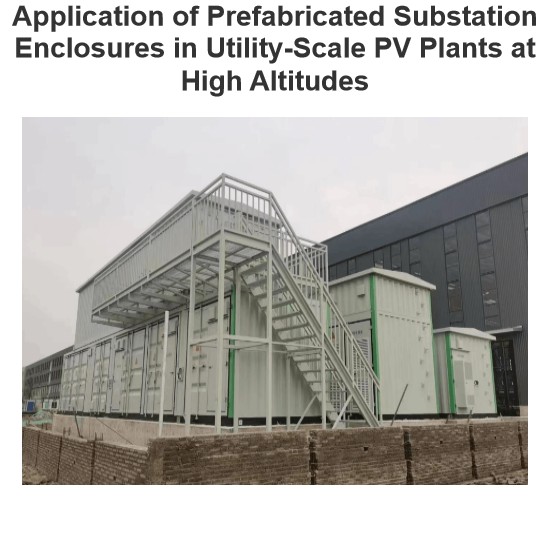

During civil construction, only the high-voltage room foundation and cable layer are built, with prefabricated cabins directly assembled above the cable layer upon arrival. Dedicated staircases (bilaterally configured with FRP rain shelters) are added, with drainage wells at the bottom connecting to sumps for stormwater discharge. This meets fire evacuation standards and facilitates operator access to the cable layer.

2.2 Factory Prefabrication and Assembly

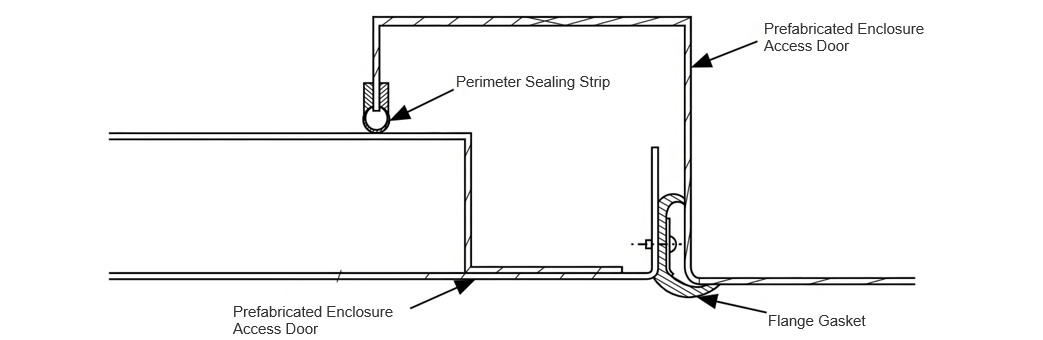

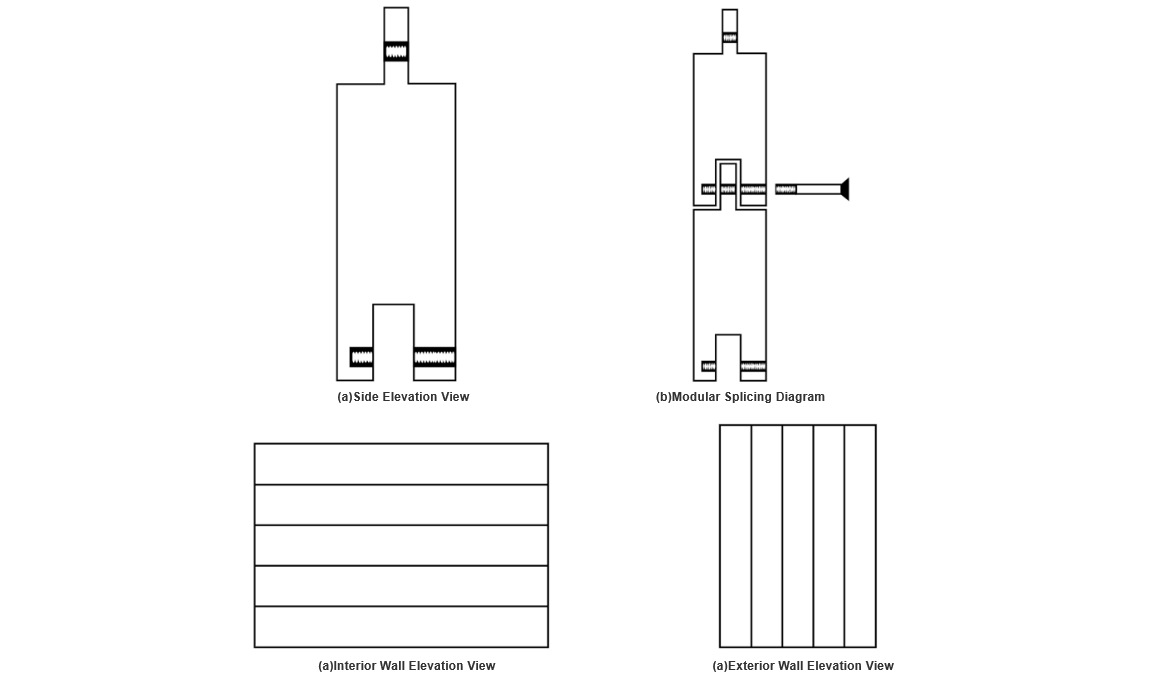

Prefabricated cabin units are configured and pre-assembled in the factory based on electrical equipment requirements, then disassembled for on-site rapid assembly. Factory installation avoids on-site quality issues from environmental or personnel factors, enabling "cabin-cabinet integrated" delivery to reduce construction workload, adapt to complex terrains, and offer significant time and cost advantages.

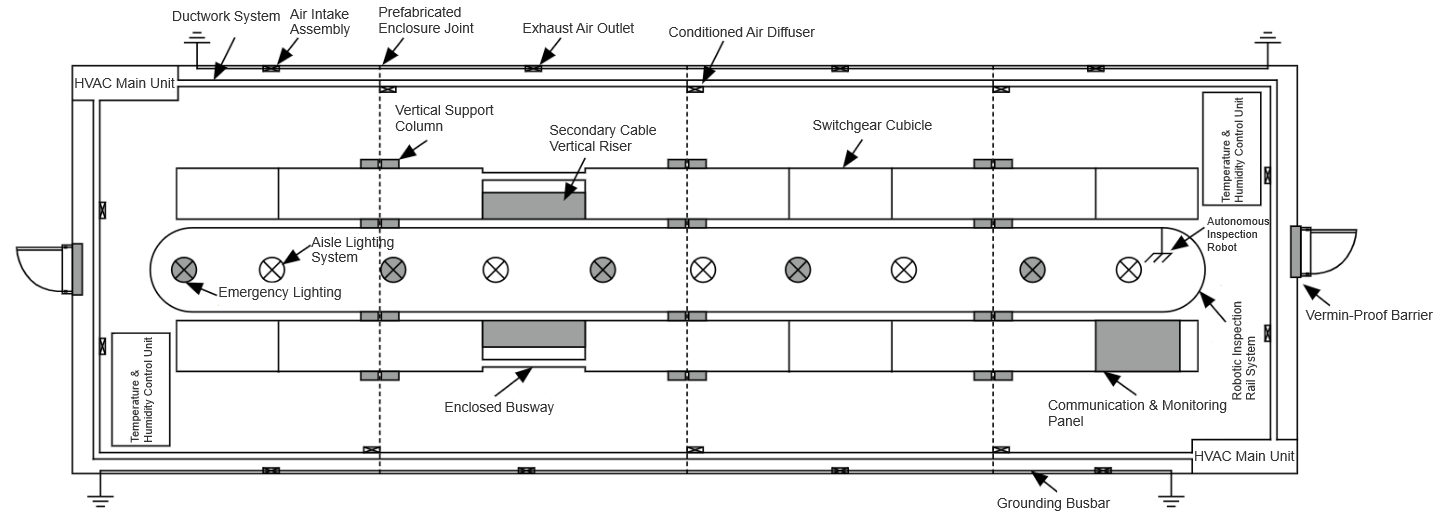

2.3 Space-Optimized Double-Layer Structure

A prefabricated control room can be built above the high-voltage room. The double-layer design transforms selected switchgear positions into secondary cable shafts, allowing cables to pass through to the upper control room, improving space utilization and reducing cable length. Square steel tube vertical struts with diagonal braces enhance mechanical strength, supporting both the double layer and inspection robot tracks for space reuse.

3 Technical Advantages

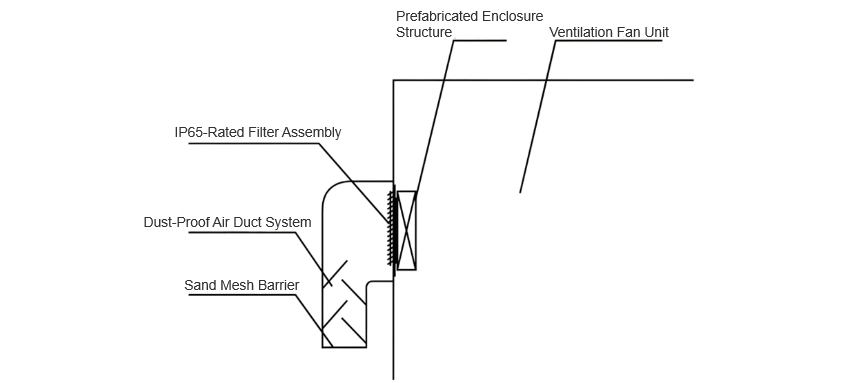

3.1 Multi-Functional Module Integration

Integration of anti-small-animal, temperature-humidity control, and patrol robot modules endows the high-voltage room with dust-proofing, thermal insulation, environmental regulation, and equipment monitoring capabilities, creating an "intelligent carrier" for power equipment.

3.2 Full Lifecycle Environmental Assurance

Automatic temperature-humidity control and decentralized air conditioning maintain stable cabin conditions, improving equipment reliability and operation comfort while preventing insulation aging and short-circuit risks from high temperatures.

4 Application Case

Under China Southern Power Grid’s 2018 New Technology Pilot Application Plan, Zhongshan Power Supply Bureau applied prefabricated technology in the 110kV Tongfu Substation, completing construction (including civil works, installation, and commissioning) within 6 months—solving traditional schedule issues. Construction material costs decreased by 25%. The 10kV prefabricated high-voltage room features a reliable structure, rational equipment layout, and perfect environmental systems, achieving organic integration of electrical equipment and cabins for long-term stable operation.

Post-operation, reduced equipment hazards, optimized environment, and improved power supply reliability cut emergency repair costs, ensured 10kV feeder load supply, and delivered significant economic and social benefits.

5 Conclusion

Aiming at traditional reinforced concrete high-voltage rooms’ "long construction period, poor environment, and weak intelligent O&M", this paper proposes a prefabricated cabin-type solution: factory debugging of cabin and equipment, followed by on-site "building block" assembly after disassembly transport. The snap-fit insulated cabin, shaft cable layout, and multi-module integration enable efficient construction and environmental optimization.

This structure supports full lifecycle equipment safety, simplifies O&M, and offers broad promotion value, providing an innovative path for smart substation construction.