Description

Designed for grounding protection in medium-voltage power grids, the 6/10kV three-phase dry-type grounding transformer adopts epoxy resin vacuum casting thin-insulation technology. Both high and low-voltage windings are wound with copper foils, ensuring partial discharge values below 10pC. Thanks to the foil winding structure, it features large interlayer capacitance and linear initial voltage distribution, delivering outstanding lightning impulse withstand capability. The windings have consistent reactance heights and balanced ampere-turns, with near-zero axial short-circuit force, ensuring excellent short-circuit resistance.

With insulation classes F/H, the transformer operates safely at 155℃/180℃ long-term. Its core uses mineral oxide-insulated cold-rolled silicon steel sheets, achieving low no-load loss and noise. Moisture-proof, flame-retardant, and self-extinguishing, it suits urban distribution networks, industrial facilities, etc. Covering capacities up to 10,000kVA, it establishes a stable neutral grounding system for ≤35kV systems.

Feature

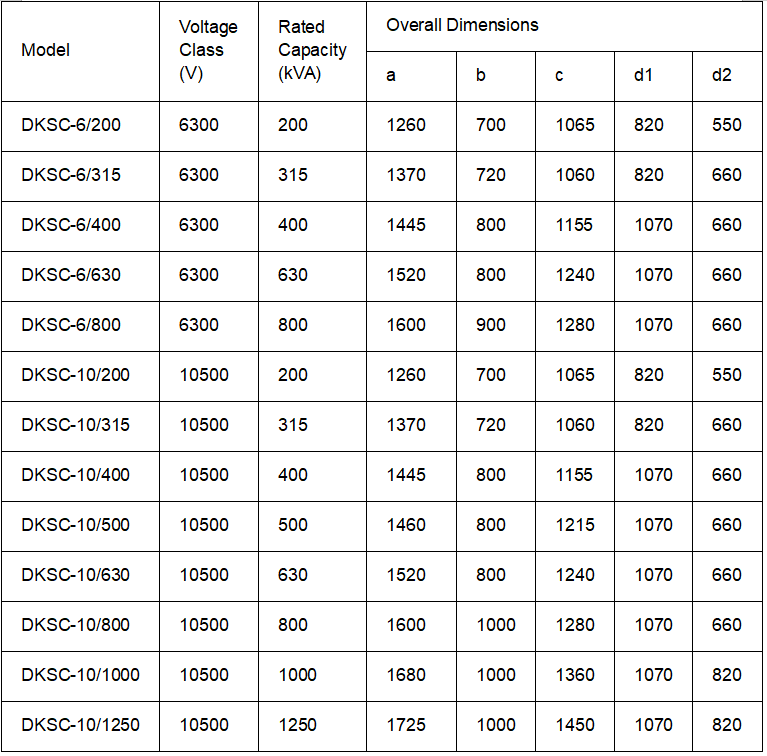

Main technical parameter

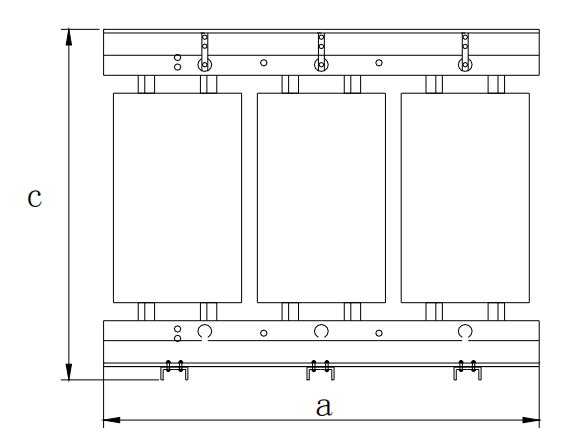

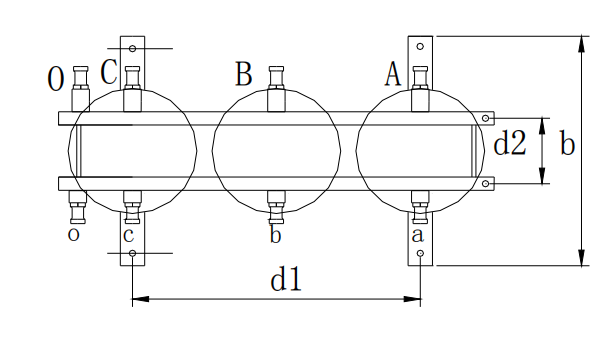

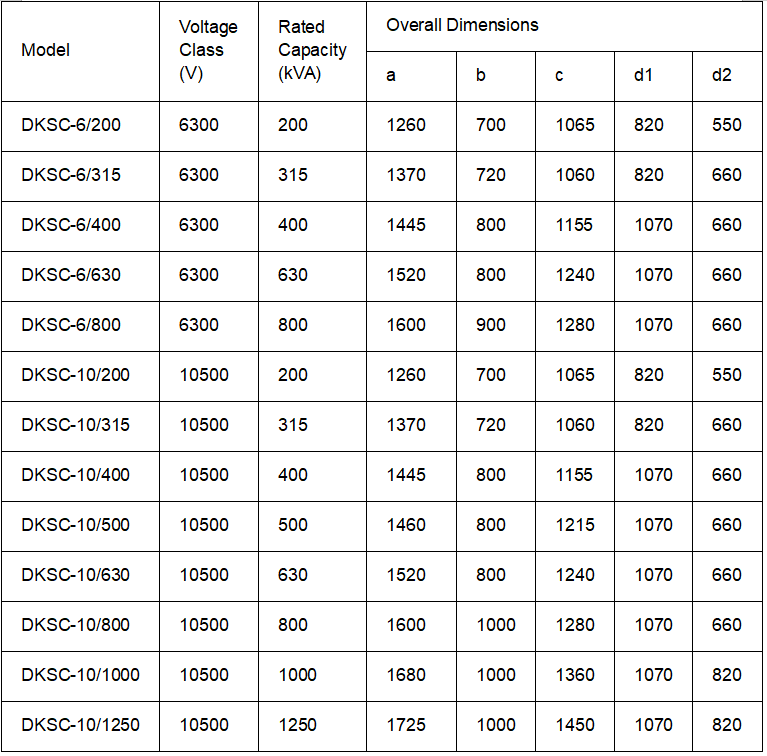

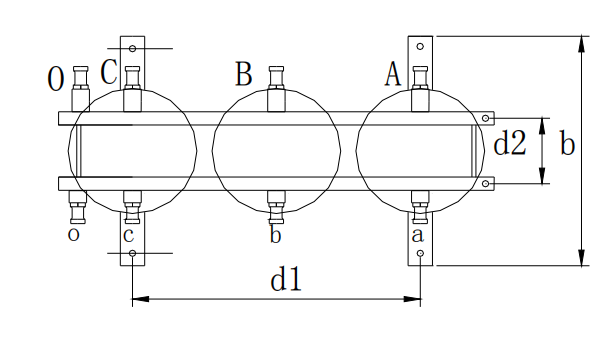

Outline Dimensions Diagram