UL Listed Three Phase Pad Mounted Power Transformer

discuss personally

Model

| Brand | Vziman |

| Model NO. | UL Listed Three Phase Pad Mounted Power Transformer |

| Rated frequency | 50/60Hz |

| Rated capacity | 2500kVA |

| Primary voltage | 33kV |

| Series | ZGS |

Description:

The UL-listed three-phase pad-mounted power transformer is an outdoor power distribution device compliant with the safety standards of Underwriters Laboratories (UL). It adopts a fully sealed pad-mounted structure, specially designed for medium and low-voltage power distribution systems. Its core characteristics are as follows:

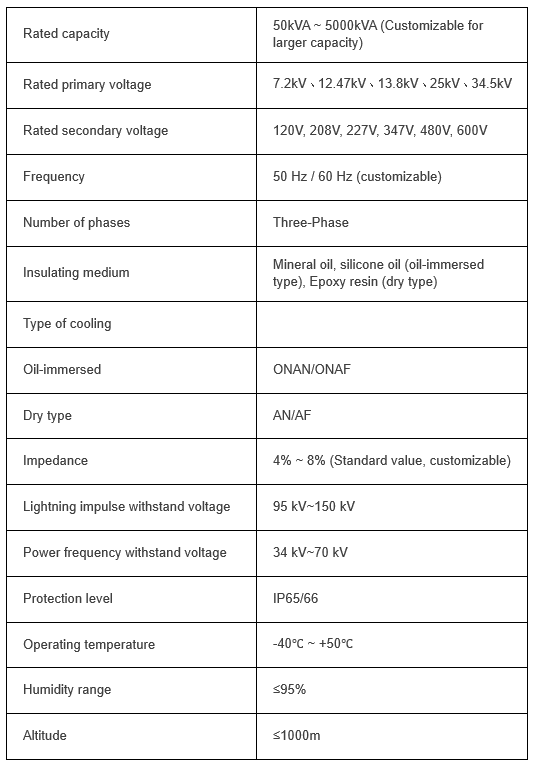

Parameter: