What are the reasons for low insulation at the low-voltage side of a dry-type transformer?

Hi everyone, I’m Felix, and I’ve been working in electrical equipment fault repair for 15 years.

Over these years, I’ve traveled across factories, substations, and distribution rooms all over the country, troubleshooting and repairing all kinds of electrical equipment. Dry-type transformers are among the most common devices we deal with.

Today, a friend asked me:

“What does it mean when the low-voltage side of a dry-type transformer has low insulation resistance?”

Great question — especially for maintenance personnel. So, I’ll explain this in simple terms, based on real-life cases I've worked on over the years.

1. What Does "Low Insulation on the Low-Voltage Side" Mean?

Let’s start with a quick overview:

A dry-type transformer is an air-cooled, oil-free, insulated transformer commonly used in buildings, malls, hospitals, data centers — places where fire safety is critical.

Its low-voltage side usually outputs 400V or 230V and directly powers the loads.

When we say "low insulation on the low-voltage side", it means that the insulation resistance between the low-voltage winding and ground (core or enclosure) is lower than normal — meaning the insulation performance has degraded.

In simple terms: what was once a fully non-conductive barrier now allows small leakage currents to pass through. This can lead to tripping, arcing, or even short circuits!

2. Common Causes (All From Real Cases I’ve Fixed)

From my field experience, the main causes of low insulation on the low-voltage side of dry-type transformers fall into the following categories:

2.1 Moisture / Condensation

This is the most common cause, especially in humid areas like southern China or coastal regions, or in newly installed transformers that haven’t dried out completely.

Example: Last year, I checked a new dry-type transformer at a factory in Xiamen. The insulation on the low-voltage side was only a few dozen megaohms — way below standard (should be ≥500MΩ). When we opened the cabinet, there was condensation inside! It turned out the unit had absorbed moisture during transport and due to high humidity.

Solutions:

- Check for water ingress;

- Use a heat gun or infrared lamp to dry it out;

- Send back to the factory for vacuum drying if necessary;

- Install a dehumidifier or space heater as prevention.

2.2 Dust or Foreign Material Buildup

Dry-type transformers rely on air for cooling, so they have many vents — which also makes them prone to dust accumulation over time.

Dust can be conductive — especially metal dust or salt particles — and when combined with moisture, it can significantly reduce insulation levels.

I once saw white crystalline deposits on the low-voltage terminals of a transformer in a chemical plant. It was caused by corrosive gases, and the insulation was clearly compromised.

Solutions:

- Clean regularly, especially around terminals and windings;

- Install filters in dusty environments;

- Use specialized insulating cleaners — never wash with water;

- Check for clogged ventilation openings.

2.3 Winding Aging or Partial Discharge Damage

The windings in dry-type transformers are typically encapsulated in epoxy resin — durable, but not indestructible.

Long-term operation under high temperatures, overloads, or harmonic conditions can cause the insulation layer to degrade, crack, or carbonize, leading to partial discharge and eventually reduced insulation.

Once, I repaired a dry-type transformer that had been in service for 8 years. Its low-voltage insulation dropped from 1000MΩ to just 20MΩ. Upon inspection, we found clear signs of carbonization on the winding surface.

Solutions:

- Check operating temperature records for long-term overheating;

- Measure partial discharge levels (if possible);

- Replace damaged windings or the entire unit;

- Improve ventilation, reduce load, and avoid frequent overloads.

2.4 Loose or Oxidized Terminal Connections

Loose terminal connections can cause localized heating, which then affects the surrounding insulation materials.

For example, I once worked on a dry-type transformer connected to a UPS system. The low-voltage insulation suddenly dropped below 100MΩ. Inspection revealed a loose copper busbar bolt — the contact area was burned and even smoked before.

Solutions:

- Regularly tighten all terminal connections;

- Use a torque wrench according to specifications;

- Check for oxidation, discoloration, or burn marks;

- Polish or replace heavily oxidized terminals.

2.5 Poor Enclosure or Grounding

The enclosure and core of a dry-type transformer must be properly grounded. If the grounding is poor, it can create floating voltages, leading to incorrect insulation readings.

Once, during a commissioning check at a new site, I found the low-voltage insulation was only a few hundred kiloohms. Turns out, the ground wire had been cut by construction workers, causing the core to become energized — falsely indicating low insulation.

Solutions:

- Check for broken or loose ground wires;

- Test ground resistance (should be ≤4Ω);

- Ensure the core is well connected to the enclosure;

- Avoid misdiagnosis due to grounding issues.

2.6 Measurement Errors / Improper Testing Methods

Sometimes, the problem isn't with the equipment itself, but how the test was conducted.

Examples include:

- Using a 500V megohmmeter instead of a 2500V one;

- Not disconnecting secondary cables or other connected devices;

- Failing to discharge before testing, causing residual charge interference;

- Ending the test too early before the reading stabilizes.

I’ve made this mistake before — almost condemned a perfectly good transformer.

Solutions:

- Use the correct megohmmeter (2500V for dry-type transformers);

- Disconnect all external wiring;

- Discharge for at least 1 minute before testing;

- Record R15 and R60 values, calculate absorption ratio (R60/R15 ≥ 1.3);

- Consider dielectric loss tests for further confirmation.

3. How to Test and Diagnose

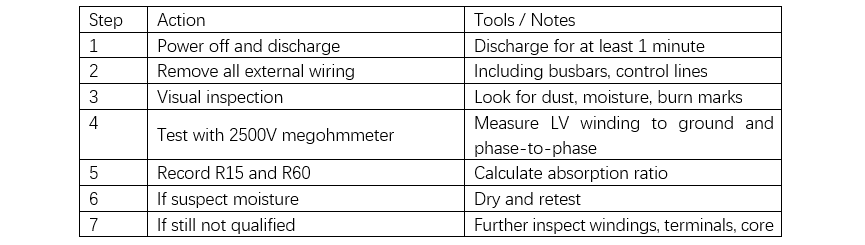

Here's the step-by-step process I use for diagnosis:

4. Repair Suggestions & Preventive Measures

Repair Suggestions:

- If moisture is the issue, drying may restore insulation;

- If dust or debris is the cause, cleaning often restores performance;

- If windings are aged or damaged, send for factory repair or replacement;

- If terminal connections are the problem, tighten or replace them;

- All operations must be done with power off, lockout-tagout applied!

Preventive Measures:

- Regular inspections (quarterly), using infrared thermography to detect hotspots;

- Periodic cleaning (annually), paying attention to hidden corners;

- Install dehumidification systems (especially in humid areas);

- Monitor load to avoid long-term overloading;

- Consider online monitoring systems (for high-end users);

- Keep detailed equipment records and track changes over time.

5. Final Thoughts

Low insulation resistance on the low-voltage side of a dry-type transformer may sound technical, but in most cases, it can be identified and resolved using basic tools and procedures.

As someone who has worked in electrical equipment repair for 15 years, I want to emphasize:

“Insulation doesn’t fail suddenly — it deteriorates slowly over time.”

With regular checks and timely maintenance, most problems can be caught early and prevented from becoming serious.

If you're dealing with a similar issue on-site and aren't sure how to proceed, feel free to reach out — we can work through it together and find the best solution.

Remember this key message:

“Prevention is better than cure — catch it early, fix it early.”

Stay safe, keep the lights on!

— Felix

Hey there! I'm an electrical engineer specializing in Failure and Maintenance. I've dedicated my career to ensuring the seamless operation of electrical systems. I excel at diagnosing complex electrical failures, from malfunctioning industrial motors to glitchy power distribution networks. Using state - of - the - art diagnostic tools and my in - depth knowledge, I pinpoint issues quickly. On this platform, I'm eager to share my insights, exchange ideas, and collaborate with fellow experts. Let's work together to enhance the reliability of electrical setups.