Vziman

Zhejiang Vziman Electric Group Co., Ltd. is a high-tech enterprise specializing in R&D, manufacturing, and service of power electrical equipment. Committed to innovation, quality, and customer satisfaction, it supplies smart solutions for global power sectors, covering grid construction, new energy, and industrial distribution.

Core Business

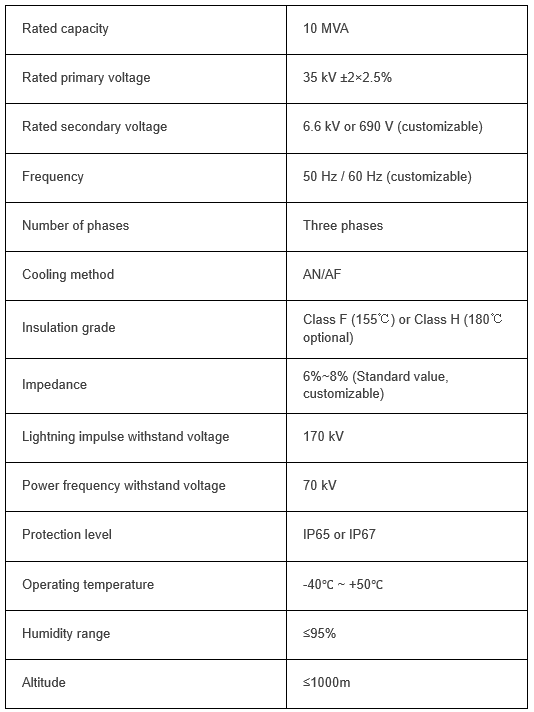

• Switchgear (GIS, circuit breakers, Recloser, Load break switch)

• Distribution equipment (transformers, RMU, smart terminals)

• Power automation systems

• Engineering services (installation, maintenance, consulting)

Technical Strength

• Provincial R&D center, multiple patents

• Modern production, ISO/GB/IEC/CE/UL certified

• High capacity, large-scale delivery support

Market & Vision

Serves State Grid, Southern Grid, and global projects (Asia, Africa, Europe, etc.). Aims to lead in smart grids and new energy, promoting sustainable energy development.