High Rupturing Capacity (HRC) Fuses: Design, Operation, and Applications

Core Functionality

HRC fuses are engineered to safely conduct short-circuit or fault currents for a specified duration. If the fault is cleared within this timeframe, the fuse element remains intact; otherwise, it melts to interrupt the circuit. Encased in an airtight container, the element is shielded from environmental factors while enabling efficient arc quenching.

Inverse Time Characteristic

HRC fuses exhibit a critical inverse time relationship:

- High-Magnitude Faults: Trigger rapid melting (short tripping time) due to intense Joule heating.

- Low-Magnitude Faults: Result in slower melting (longer tripping time), enabling coordination with other protective devices.

Arc Extinguishing Mechanism

During a fault:

- The fuse element melts, creating an arc.

- The enclosure, filled with quartz sand or other inert powders, reacts with the vaporized metal to form a high-resistance plasma.

- This plasma rapidly dissipates the arc energy, preventing re-ignition and ensuring safe circuit interruption.

Cartridge Type HV HRC Fuse

Design Features:

- Ring-Shaped Element: Wound to eliminate corona discharge, a high-voltage phenomenon causing energy loss and interference.

- Dual-Element Configuration (selected models):

- Normal Current Path: A low-resistance copper or silver element handles steady-state loads.

- Fault Current Path: A parallel tungsten element, optimized for high resistance and melting point, ensures rapid response to short circuits.

- Corona Mitigation: The toroidal shape equalizes electric fields, minimizing ionization and enhancing performance in HV environments.

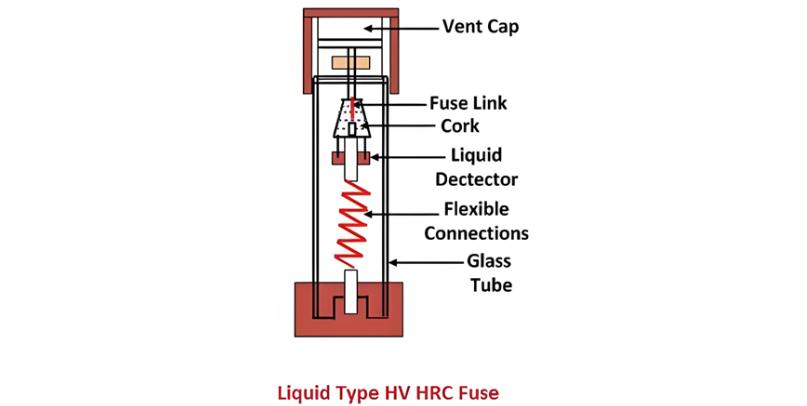

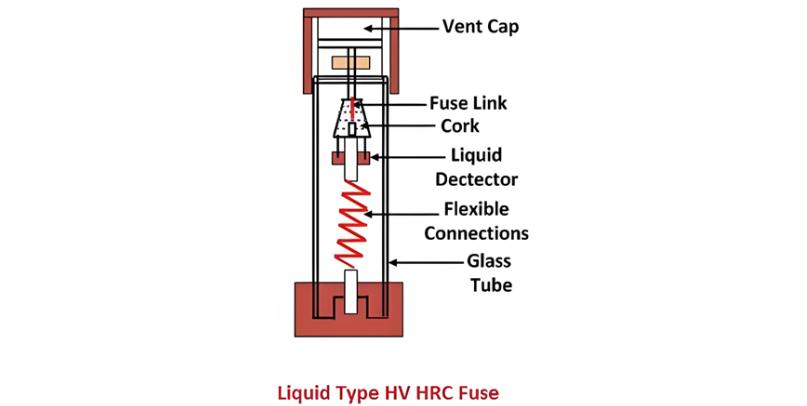

Liquid Type HV HRC Fuse

Applications:

- High-voltage circuits (>400A), particularly transformer protection and industrial systems.

Construction

- Glass Tube Enclosure: Filled with carbon tetrachloride, a non-conductive liquid with excellent arc-quenching properties.

- Element Placement: The fuse element is immersed in the liquid, with one end sealed and the other connected via a phosphorous bronze wire.

- Arc Suppression: Upon melting, the element decomposes the liquid into non-conductive gases, rapidly extinguishing the arc and dissipating heat. This design excels in high-energy fault scenarios, outperforming dry-type fuses.

Backup Protection for Circuit Breakers

Liquid-type HRC fuses serve as backup protectors for circuit breakers, enhancing their short-circuit capacity. In the event of a fault exceeding the breaker’s interrupting rating, the fuse rapidly interrupts the current, preventing damage to the breaker and downstream equipment. This cooperative design ensures reliable protection in high-power systems.

Advantages & Limitations

Key Benefits:

- Precision Fault Response: Reliable interruption across a wide current range.

- Safety: Airtight enclosures prevent explosive hazards and external arcing.

- HV Compatibility: Specialized designs address high-voltage challenges like corona and arc stability.

Limitations

- Single-Use: Requires replacement after operation.

- Environmental Sensitivity: Liquid-type fuses may require temperature compensation, and cartridge fuses necessitate periodic inspection.

In summary, HRC fuses are indispensable for power system protection, combining advanced materials science and engineering to deliver rapid, reliable fault interruption in diverse electrical applications.