Solution principle for high voltage vacuum interrupter

Enhancing Dielectric Strength in Vacuum Gaps for High-Voltage Insulation

There are primarily two methods to increase the dielectric strength of a vacuum gap to meet the insulation requirements at high voltage (HV):

Increase the Contact Distance in a Two-Contact Configuration: In a vacuum, breakdown is predominantly a surface effect, heavily influenced by the condition of the contact surfaces. Unlike in SF6 gas, where breakdown is primarily a volume effect that scales linearly with the gap length, vacuum breakdown is more dependent on the quality and condition of the contact surfaces. The dielectric strength in a vacuum exhibits excellent performance even with small gaps (2–4 mm), but it gradually saturates as the gap length increases beyond this range. Therefore, increasing the contact distance can enhance the dielectric strength, but only up to a certain point, after which further increases in gap length yield diminishing returns.

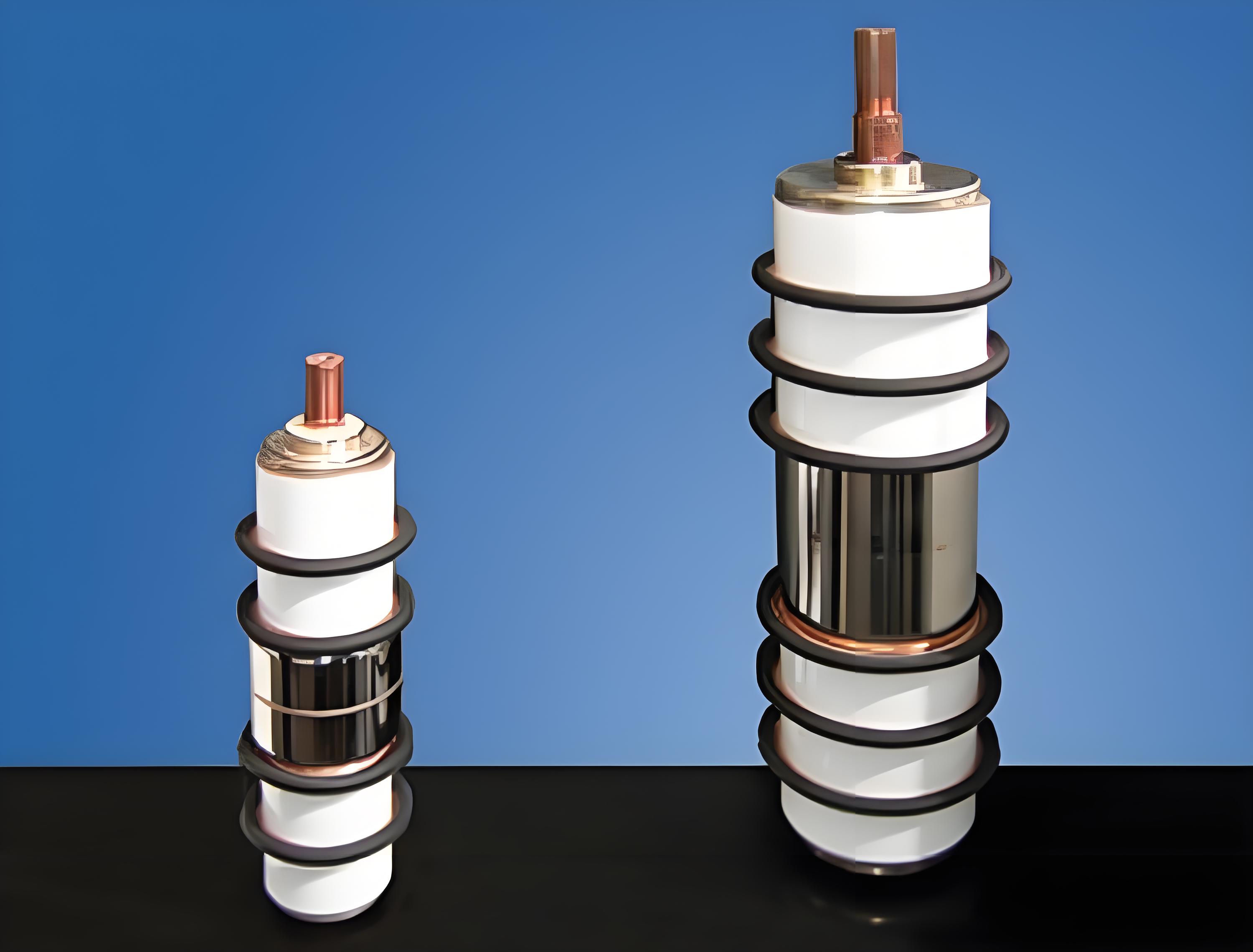

Place Two or More Gaps in Series (Multi-Break Circuit Breakers): Multi-break circuit breakers are designed to distribute the voltage uniformly across multiple gaps, ensuring consistent performance during both normal operation and switching events. By placing two or more gaps in series, the necessary withstand voltage level can be achieved with a total contact distance that is smaller than what would be required with a single gap. This approach leverages the principle of ideal voltage sharing between the gaps, where each gap shares an equal portion of the total voltage. Grading capacitors are often used to ensure uniform voltage distribution across all breaks, further enhancing the system's reliability and performance.

Advantages of Multi-Break Configuration:

Smaller Total Gap Length: Achieves the required dielectric strength with a shorter overall contact distance compared to a single-gap configuration.

Improved Voltage Distribution: Ensures that each gap bears an equal share of the voltage, reducing stress on individual contacts and improving overall system stability.

Enhanced Reliability: Reduces the likelihood of breakdown by distributing the voltage across multiple points, making the system more robust against transient overvoltages.

In summary, while increasing the contact distance in a two-contact configuration can improve dielectric strength in a vacuum, it is limited by the saturation effect for longer gaps. On the other hand, placing multiple gaps in series, especially with the use of grading capacitors, offers a more efficient and reliable way to achieve the necessary dielectric strength for high-voltage applications. This method allows for better voltage distribution and can significantly reduce the total contact distance required, making it a preferred choice for high-voltage insulation in multi-break circuit breakers.