| Brand | RW Energy |

| Model NO. | RWV-300 High Performance AC DRIVE |

| Output current | 10A |

| Power capacity | 4kVA |

| Input current | 21A |

| Adapt motor | 2.2kW |

| Series | RWV |

Description :

A Variable Frequency Drive (VFD) is a power control device widely used in the field of industrial automation. It integrates functions such as motor control, energy-saving regulation, communication, and monitoring, enabling precise speed control and operational status management of AC motors.The VFD adopts a modular design concept, offering high flexibility and programmability, which significantly reduces maintenance workload and spare parts requirements while meeting diverse application needs. As an ideal alternative to traditional motor control methods, the VFD provides notable advantages in improving energy efficiency, optimizing control accuracy, and extending equipment lifespan.

Main function introduction:

Chinese and English LCD display, easy to install and debug;

The Japanese wide and large structure, the product margin is large,

Can be used in hot weather occasions;

With speed tracking function, can be a good application of fan secondary start;

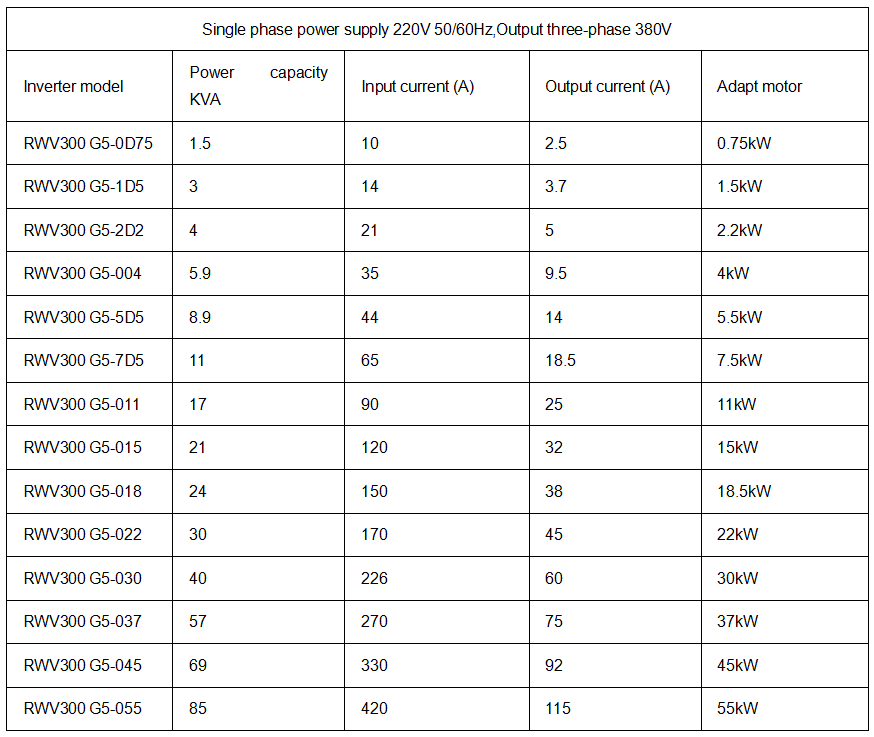

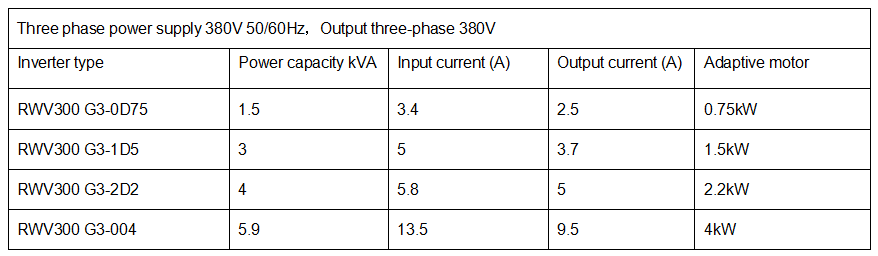

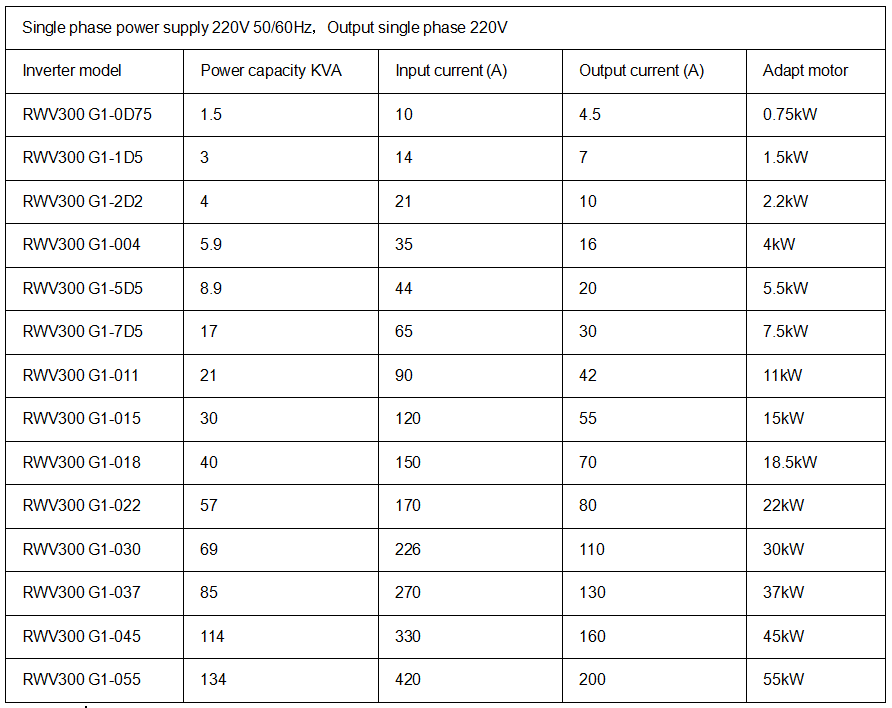

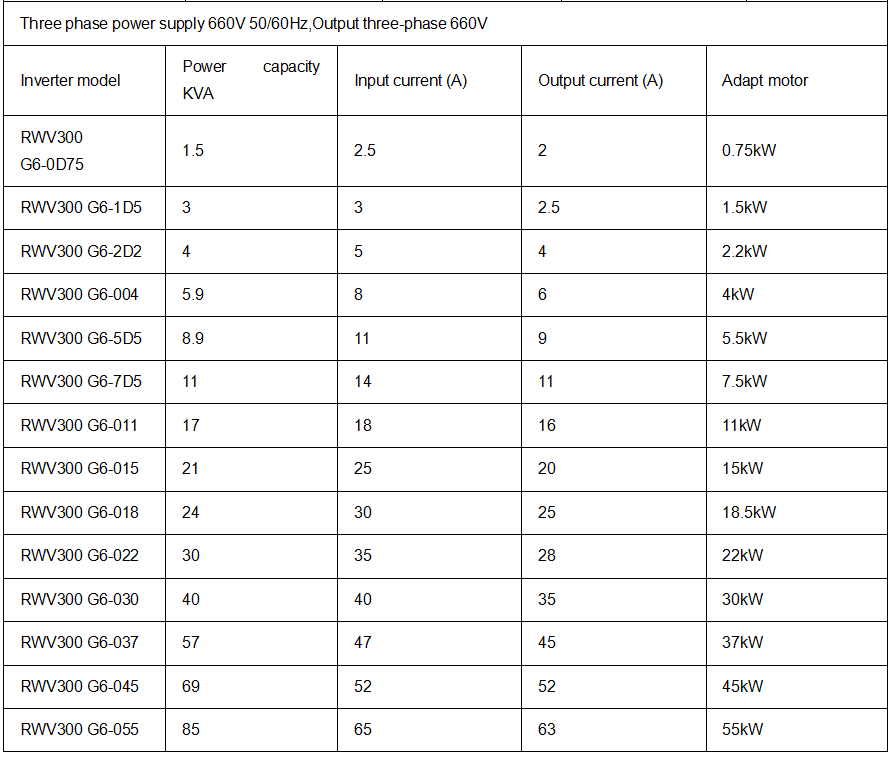

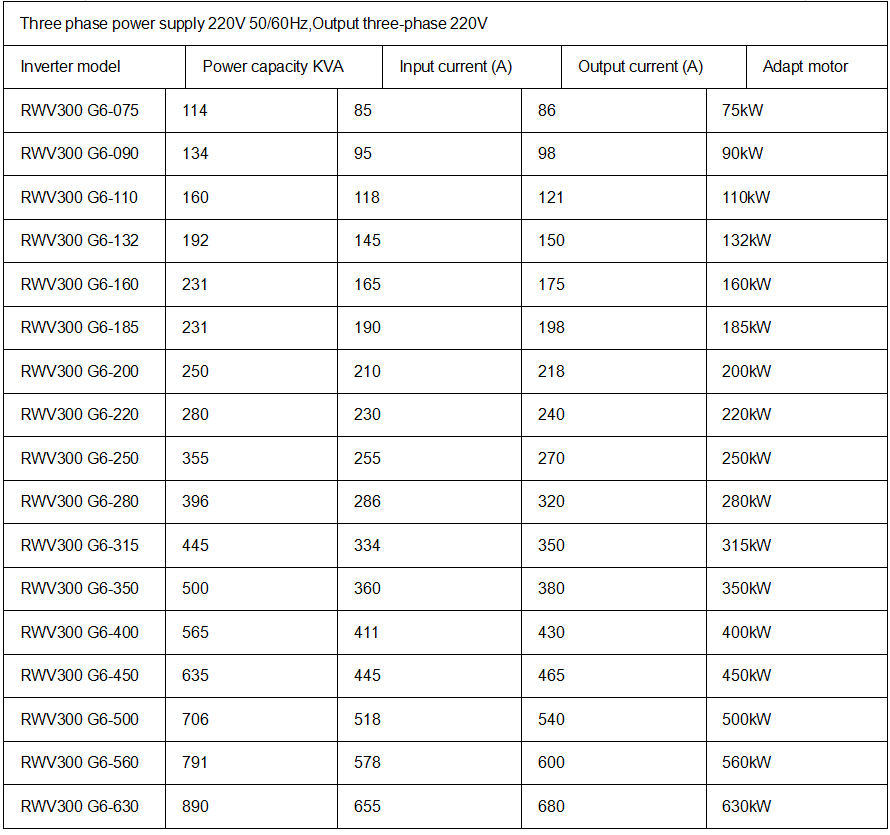

Can do 220V, 380V, or 220/380 and other voltages;

With short circuit, grounding and other protection;

Can add master/slave control card, communication expansion card, PG card;

Asynchronous motor, synchronous motor optional;

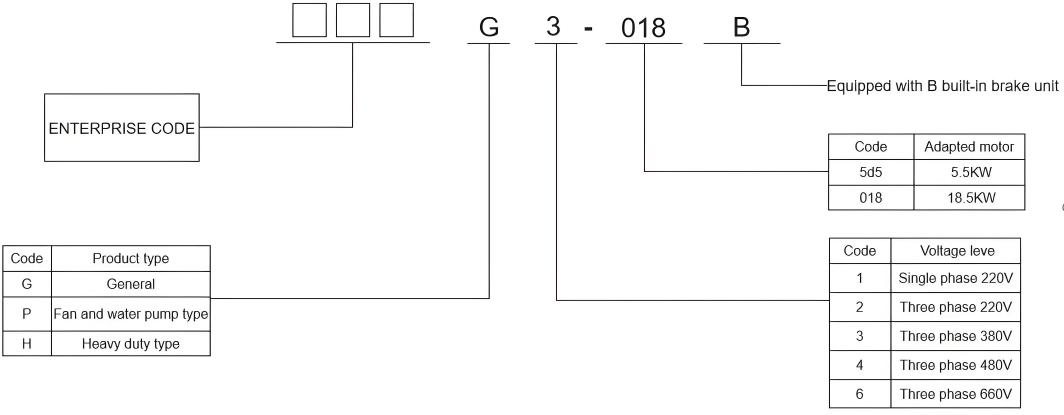

Product model description:

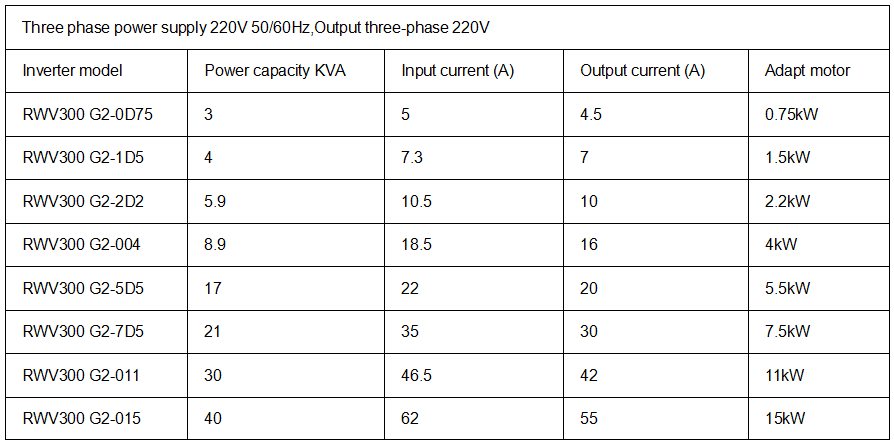

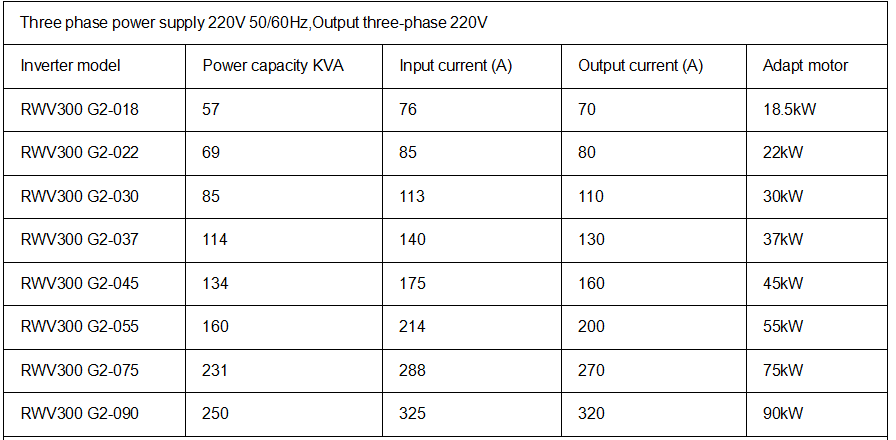

Technology parameters:

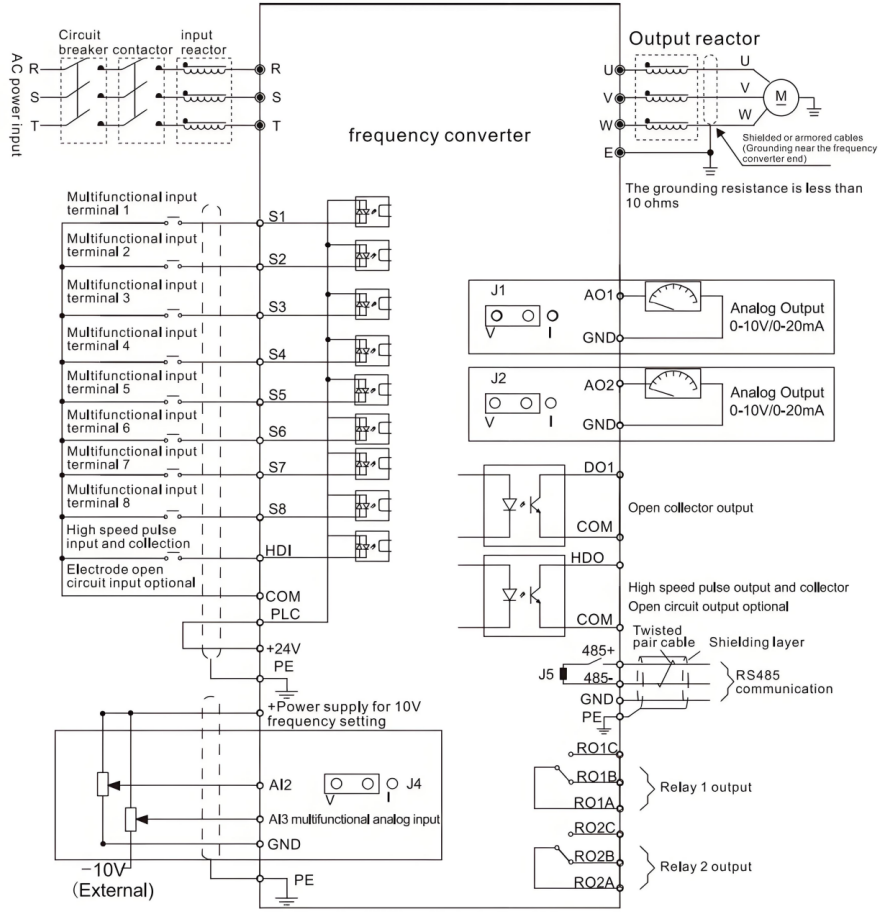

Wiring Schematic Diagram :

What is a variable frequency drive?

A variable frequency drive is an electronic device that can convert alternating current (AC) of a fixed frequency into AC with adjustable frequency and voltage, thereby controlling the speed and torque of an electric motor. It mainly consists of a rectifier that converts AC into direct current (DC). After voltage stabilization in the DC link, an inverter then converts the DC back into AC with the required frequency and voltage. It is widely used in industries, heating, ventilation, and air - conditioning (HVAC) systems, the automotive sector, etc., to achieve motor speed regulation, energy conservation, and precise operation control.