| Brand | ROCKWILL |

| Model NO. | 15.6kV MV Auto Circuit outdoor vacuum recloser |

| Rated voltage | 15.6kV |

| Rated normal current | 630A |

| Rated short circuit breaking current | 16kV |

| Power frequency withstand voltage | 60kV/min |

| Rated lightning impulse voltage | 125kV |

| manual closing | No |

| Series | RCW |

Description:

The RCW series automatic circuit reclosers can use on overhead distribution lines as well as distribution substation applications for allvoltage classes 11kV up to 38kV at 50/60Hz power system. and it’s rated current can reach 1250A.The RCW series automatic circuit reclosers integrates the functions of control, protection, measurement, communication, fault detection, on-line monitoring of closing or opening.The RCW series vacuum recloser is mainly combined with integration terminal, current transformer, permanent magnetic actuator and it’s recloser controller.

Features:

Optional grades available in rated current range.

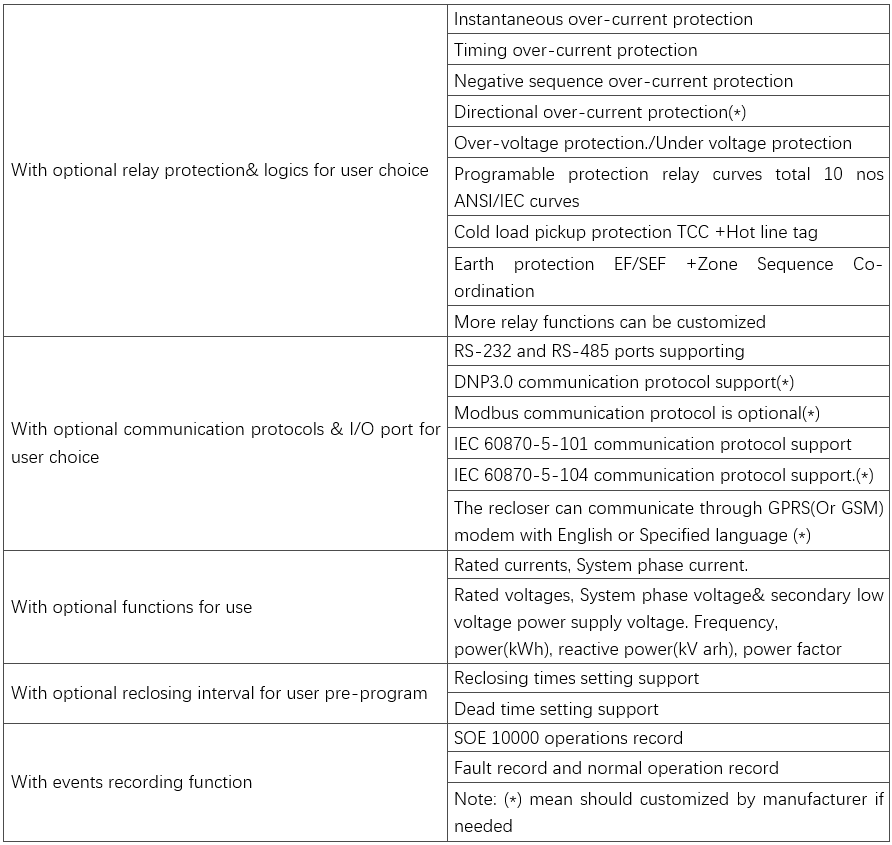

With optional relay protection and logic for user selection.

With optional communication protocols and I/O ports for users to choose.

PC software for controller testing, setup, programming, updates.

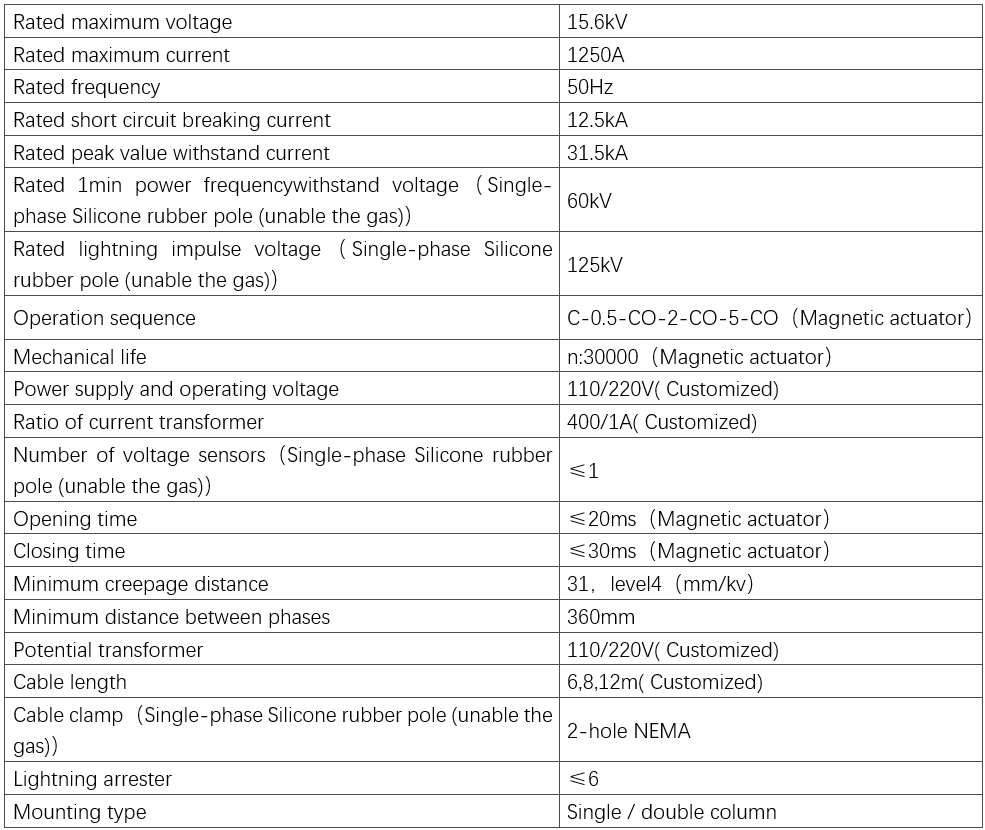

Parameters:

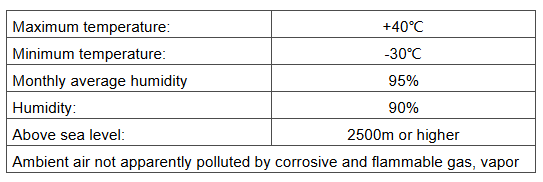

Environmental requirement:

Product show:

What are the technical parameters of the outdoor vacuum recloser?

Rated Voltage: 38kV, indicating the voltage level at which the recloser can operate normally. This ensures that the insulation and electrical performance of the device meet the required standards at this voltage.

Rated Current: Available in various specifications, such as 800A, 1200A, etc. This represents the maximum current that the recloser can carry continuously during normal operation. The appropriate rated current value should be selected based on the load current of the line.

Rated Short-Circuit Breaking Current: Reflects the breaking capability of the recloser during short-circuit faults. Common specifications include 16kA, 20kA, etc. A higher short-circuit breaking current indicates that the recloser can more reliably interrupt short-circuit currents, protecting the safety of the power system.

Rated Short-Circuit Making Current: Represents the maximum peak current that the recloser can close during a short-circuit fault. This value is typically greater than the rated short-circuit breaking current to ensure that the recloser can reliably close and withstand the impact of short-circuit currents at the moment of fault.

Reclosing Time Interval: Generally adjustable between 0.5 seconds and several seconds. Depending on the requirements of different power systems and types of faults, an appropriate reclosing time interval can be set to enhance the reliability and continuity of power supply.