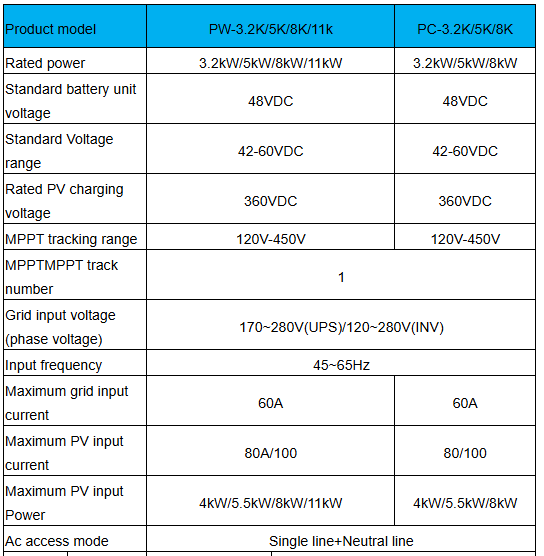

| Brand | Wone |

| Model NO. | PC/PW PV inverter |

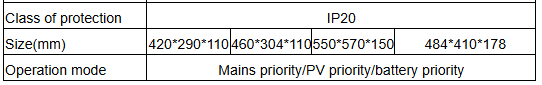

| Mounting type | rackmounting |

| Rated Output Rating | 8kW |

| Input Voltage | DC48V |

| Rated PV input power | 8kW |

| Series | PC/PW series |

Photovoltaic inverter

Peculiarity:

Dual phase inverter.

IP54 protection grade, support outdoor use.

Backward compatible with traditional lead batteries, colloidal batteries.

PC/PW up to 9 parallel, output power up to 45KW.

The panel integrates a variety of interfaces, supporting a variety of protocols of the host computer and battery pack.

Integrated MPPT, maximize the press of the remaining power of the photovoltaic panel.

Highly integrated, feature-rich, one machine at most.

Can be customized adjustment management battery charging and discharging strategy.

Modular design, easy maintenance.

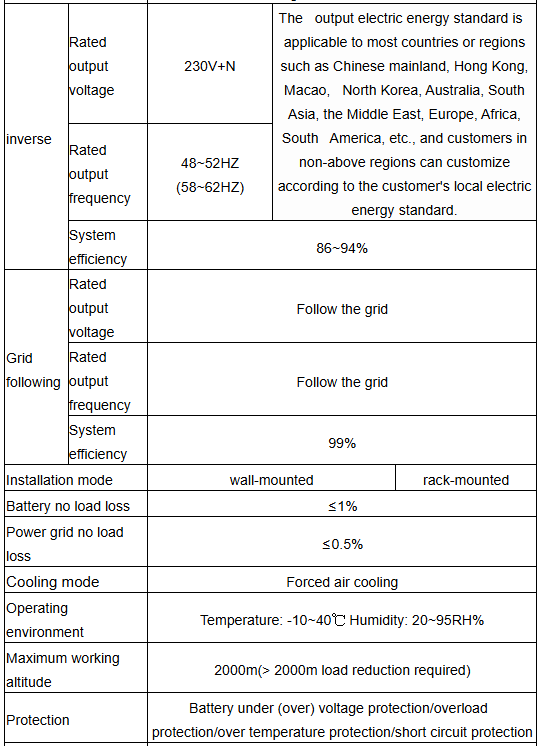

Technical parameter:

How does MPPT dynamically adjust the input voltage and current?