| Brand | ROCKWILL |

| Model NO. | Outdoor RPS-27kV/630A SF6 load break switch |

| Rated voltage | 27kV |

| Rated normal current | 630A |

| Power frequency withstand voltage | 50Hz |

| Mainly active load breaking current | 1250A |

| Series | SF6 |

Description:

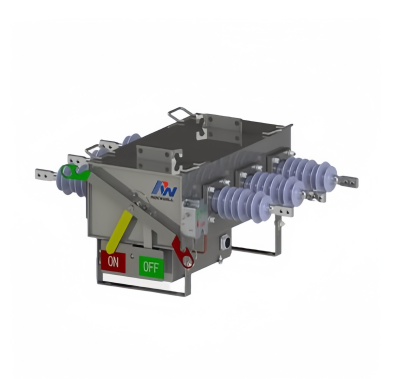

This is a high standard design SF6 gas load break switch which is suit for pole mounted.

RPS type load break switch is KEMA type tested.

RPS type load break switch can combined as below different functions switchgear.

Manual type load break switch.

Motorize type load break switch.

Remote control load break switch.

Automatic sectionalizer.

Features:

the high quality 3 mm stainless steel are used for tank.

minimum welding line to minimize corrosion, and specifically to guarantee the safety of the operation personnel.

even with the internal arc faults at the maximum fault capacity of the tank the RPS can withstands an internal fault without venting hot gases.

the independent spring operation mechanism adopt ROCKWILL® patent spiral spring, provides a guaranteed load break fault make capability by ensuring. the opening and closing speed of the switch.

provided with light reflecting position indicator which are directly connected to the switch operating shaft providing clear and unambiguous switch position. indication

indicator made of light reflecting material, which is easily visible from ground level even at night in driving rain.

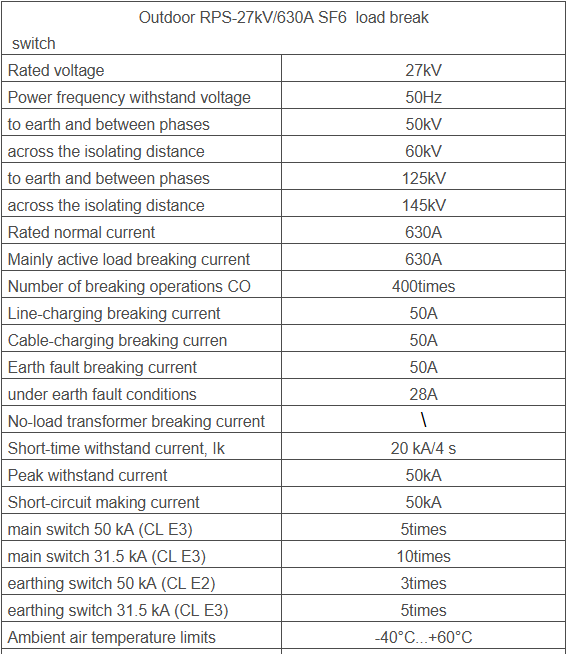

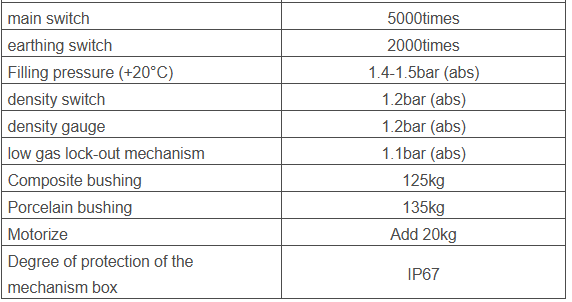

Parameters:

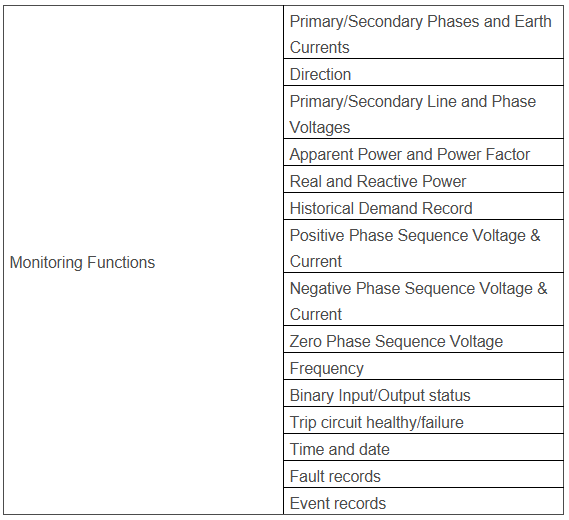

Monitoring Functions:

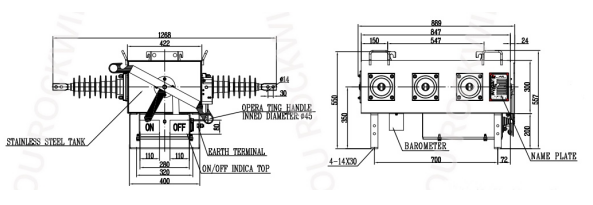

External dimensions:

Size |

889mmx1268mmx557mm |

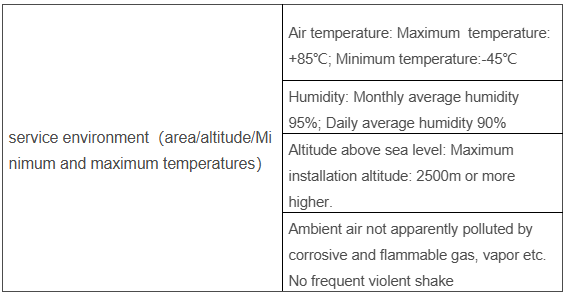

Environmental requirement:

Product show:

How to maintain and manage the outdoor load disconnect switch?

Visual Inspection: Conduct regular visual inspections to ensure that the switchgear's housing, connection points, and seals are free from obvious damage or corrosion.

Internal Inspection: Perform regular internal inspections, particularly of critical components such as the arc quenching chamber, contacts, and insulating parts, to ensure they are in good condition.

Functional Testing: Carry out regular functional tests, including opening and closing operations, insulation resistance testing, and dielectric strength testing, to ensure all functions of the switchgear are operating correctly.

Pressure Monitoring: For outdoor load break switches using SF6 gas, regularly monitor the SF6 gas pressure in the arc quenching chamber to ensure it remains within the specified range.

Leakage Detection: Use leakage detection equipment to regularly check for SF6 gas leaks, and address any detected leaks promptly.

Temperature Control: Control the installation environment's temperature to avoid high or low temperatures that could affect the performance of the switchgear.

Moisture Protection: Implement moisture protection measures to prevent water from entering the switchgear, which could impact its insulation performance and the normal operation of mechanical components.