| Brand | Wone |

| Model NO. | MC Series Flexible Cable For Coal-mining |

| Rated voltage | 0.38/0.66kV |

| 芯数 | 3+1+3-core |

| alloy code | TU2 |

| Series | MC |

Application

It is suitable for rated voltage Uo/U 1.9/3.3KV coalmining machine and the similar equipments.

Application conditions

The long-term permissible working temperature of cable conductor for rated voltage up to and including 0.38/0.66kV is 90 ,Black jacket.

The long-term permissible working temperature of cable conductor for rated voltage up to and including 0.66/1.44kV is 90 ,Yellow jacket . and that of the cable conductor of rated voltage1.9/3.3kV is 90℃ It’s smallest bending radiusis 6 times than the size of cable diameter. The yellow sheathed cables can’t be exposed in the sun for a long time.

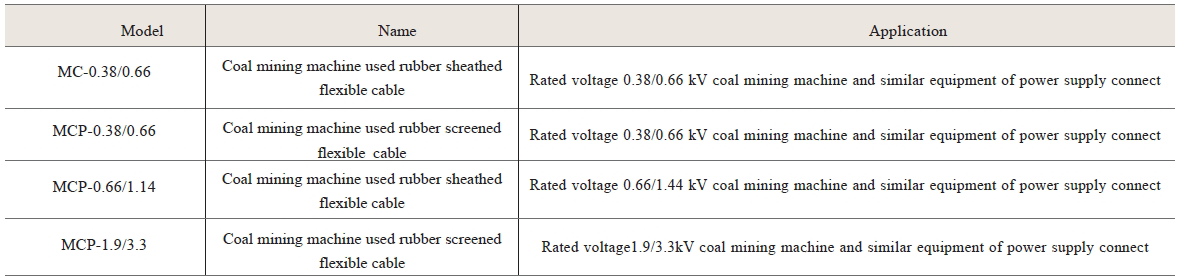

Model and names

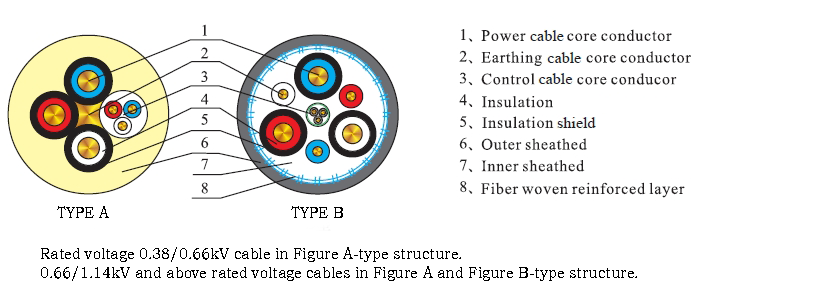

Structure diagram

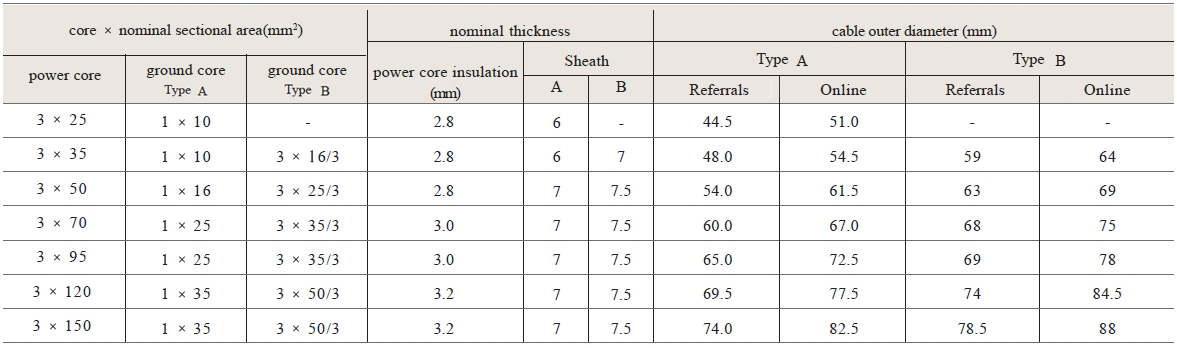

Specification size

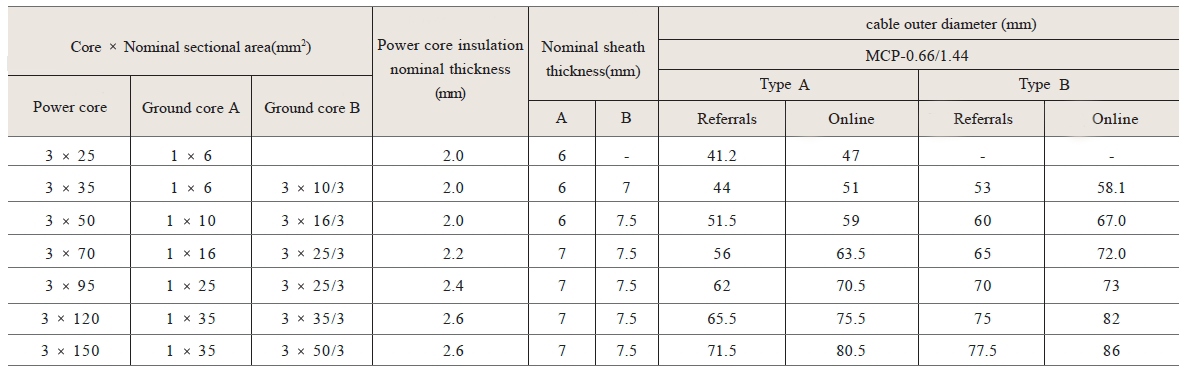

Rated voltage 0.66/1.14kV cable dimensions

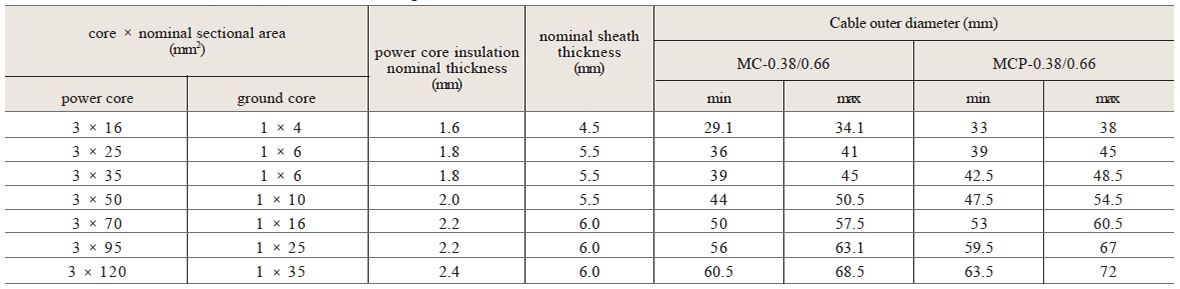

Rated voltage 0.38/0.66kV cable dimensions

Rated voltage 1.9/3.3kV cable dimensions

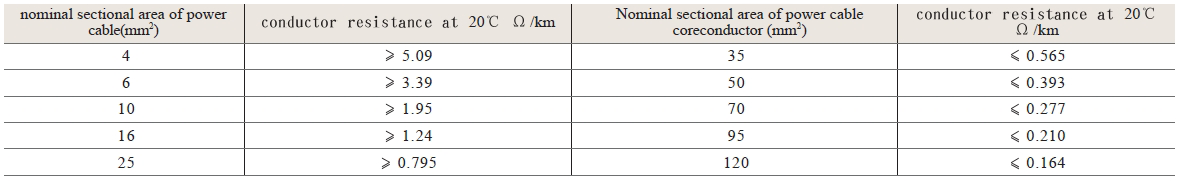

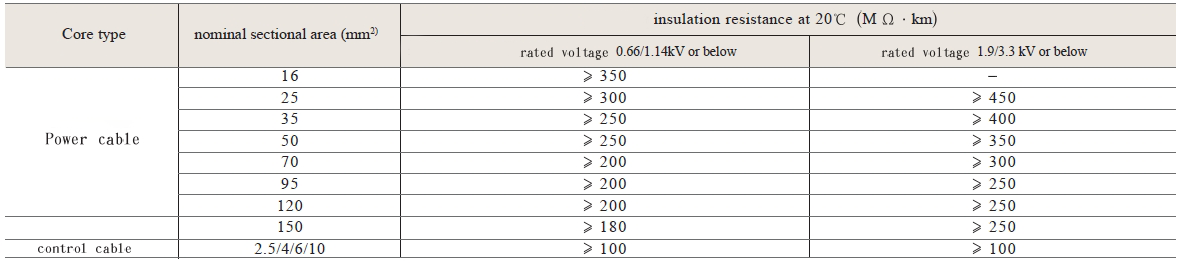

Technical parameter

Finished DC resistance

Finished insulation resistance

a. Conductor temperature of 90℃ to allow work;

b. it has the anti-bending characteristics;

c. it has the anti-extrusion and anti-pressure characteristics;

d. Insulation tensile strength greater than 6.5Mpa, more than 200% elongation;

e. Max anti-bending 11.0 N/mm2, Max anti-tensible force>250%;

f. No damage under rated voltage 0.38/0.66kV for 3.0kV/5min,0.66/1.14kV for 3.7kV/5min, 1.9/3.3kV for 6.8kV/0.5min respectively;

g. It complies with fire-proof feature based on MT386-1995.

Q: What is MC cable?

A: MC Cable is Metal Clad Cable. It consists of a combination of insulated wires and is covered with a metal sheath. This cable has good mechanical protection performance and can resist external physical damage such as extrusion and collision to a certain extent.

Q: What are the main application scenarios of MC cables?

A: MC cable is often used in commercial buildings, industrial facilities, mining sites and other places. In commercial buildings, such as shopping malls, office buildings, etc., it can be used for electrical wiring systems to power lighting, sockets and other equipment. In industrial facilities, such as factory floors, due to the complex environment, the metal sheathing of MC cables can provide additional protection and is suitable for connecting power to various types of machines and equipment. Because of its excellent defensive performance, it is often used in mining, metallurgy and other fields.

Q: What are the advantages of MC cable?

A: Its advantages include high safety, metal sheath can be used as a grounding path; The installation is relatively flexible, and can be laid under a variety of ways such as bridge and cable trough. And has a good electromagnetic compatibility, can reduce the electromagnetic interference to the surrounding equipment.