| Brand | Rockwell |

| Model NO. | LVB Oil immersed current transformer |

| Rated voltage | 40.5kV |

| Series | LVB |

Product introduction:

The LVB series current transformers feature oil-impregnated paper insulation and an inverted structure, complying with IEC/IEEE standards. Installed in power lines, these series-connected transformers enable functions including energy measurement, metering, relay protection, and transient protection.

Product features:

Robust Primary Winding Design

The through-type conductive rod structure ensures exceptional dynamic and thermal stability, with a maximum thermal stability current of 63kA/3s (in series configuration).

Ultra-Precise Measurement

The primary winding passes through the center of the secondary winding, eliminating magnetic flux leakage and achieving measurement accuracies of 0.2S and 0.1.

Enhanced Secondary Protection

Secondary windings are encapsulated in an aluminum-shielded housing with organic materials, safeguarding measurement and protection circuits from electrical breakdown.

Advanced Capacitor Screen Bushing

Wound by a high-performance computer-controlled automatic wrapping machine using imported wide-width cable paper, the bushing ensures minimal process variation and excellent insulation. Partial discharge tests are conducted under power frequency voltage to guarantee reliability.

German-Made Vacuum Drying Technology

Utilizing a LEYBOLD imported fully automatic vacuum drying system, the transformer undergoes variable-pressure vacuum drying and oil injection after assembly. Fully imported insulating materials ensure the overall dielectric loss factor (tanδ) remains below 0.3%.

Uniform Insulation Wrapping

The head insulation is applied by an automatic binding machine, ensuring consistent, tight, and uniform wrapping for optimal performance.

Weatherproof Secondary Outlet Box

The one-piece aluminum alloy casting features a dust-proof, waterproof, and breathable sealing structure for reliable outdoor operation.

Leakage-Proof Construction

All component connections use argon arc welding, and the assembly is leak-tested with high-pressure nitrogen, eliminating oil leakage issues typical in oil-immersed products.

Corrosion-Resistant Materials

The shell, base, and junction box are crafted from aluminum alloy, while the expander and nameplate use stainless steel—all exposed parts are rust-proof for lifelong durability.

Maintenance-Free Operation

Designed for minimal upkeep, the transformer reduces long-term operational costs and downtime.

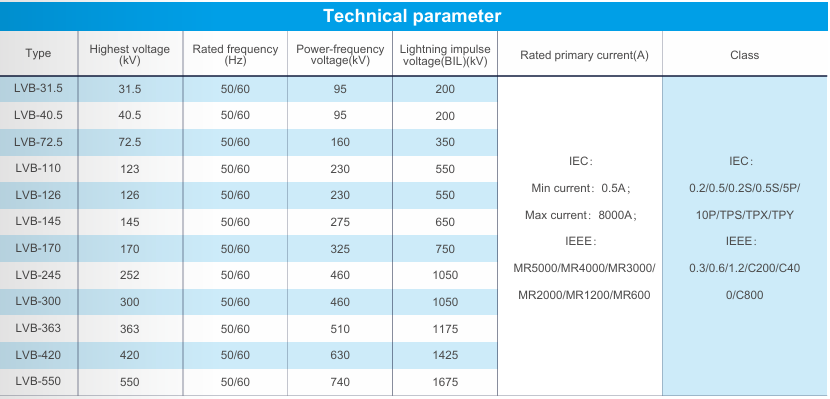

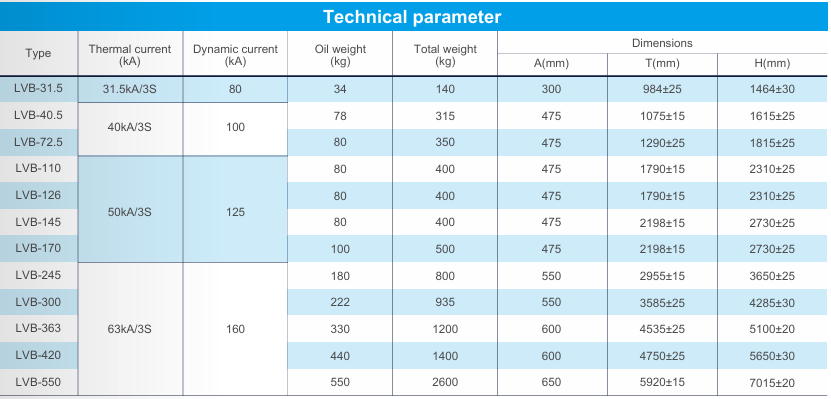

Technical parameter:

Remark: Approximate dimensions and weights for special requirements, please consult us.