| Brand | Vziman |

| Model NO. | Amorphous alloy dry-type transformer 200KVA 250KVA 315KVA 400KVA |

| Rated capacity | 400kVA |

| Voltage grade | 15KV |

| Series | SC (B) H15 |

Description

The amorphous alloy dry-type transformer represents a mature energy-saving solution in dry-type transformer technology. This product stands out for its low no-load loss, flame-retardant self-extinguishing properties, moisture resistance, crack resistance, and maintenance-free operation. Ideal for replacing conventional dry transformers, it is widely applicable in high-rise buildings, commercial centers, subways, airports, stations, industrial and mining enterprises, and power plants. Specifically designed for installation in fire-sensitive environments, it is particularly suitable for flammable or explosive zones, meeting strict fire protection requirements with optimal safety and reliability.

Key Advantages

Energy Efficiency: Significantly reduces no-load loss, contributing to lower operational costs and environmental sustainability.

Safety Features: Self-extinguishing and flame-retardant design minimizes fire risks, while moisture and crack resistance ensure stable performance in diverse conditions.

Versatile Application: Compatible with all scenarios using traditional dry transformers, including high-density urban infrastructure and industrial settings with strict safety norms.

Low Maintenance: Engineered for hassle-free operation, eliminating the need for regular upkeep and enhancing system durability.

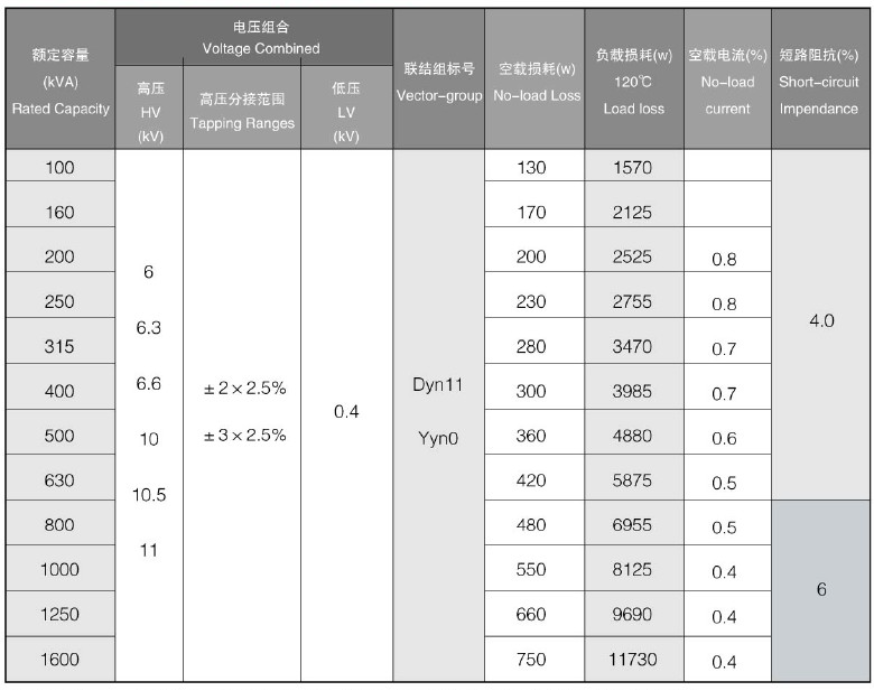

Parameter:

What is an amorphous alloy dry-type transformer?

Amorphous Alloy Dry - type Transformer is a kind of dry - type transformer that uses amorphous alloy material as the iron core. The amorphous alloy material has unique physical and chemical properties, which enable it to exhibit excellent performance in transformer applications. This kind of transformer is widely used in situations where high energy - efficiency and environmental - protection requirements are emphasized.

Amorphous Alloy: An amorphous alloy is a metallic material with an amorphous structure, usually composed of elements such as iron, boron, and silicon. The atomic arrangement of this material does not have a fixed lattice structure, thus possessing unique physical and chemical properties.

Dry-type Transformer: A dry-type transformer is a type of transformer that does not use a liquid cooling medium (such as transformer oil). It usually adopts natural air cooling or forced air cooling.

Iron Core: The iron core made of amorphous alloy material has extremely low hysteresis loss and eddy current loss.

Coil: Usually wound with copper or aluminum wires, it has good electrical properties.

Insulation Materials: High-quality insulation materials such as epoxy resin are used to ensure the safety of the transformer operating under high voltage.

Cooling Methods: Generally, natural air cooling (AN) or forced air cooling (AF) is adopted. The appropriate cooling method is selected according to specific application requirements.