36kV/38kV Indoor Vacuum Servo Motor Controlled Switching Circuit Breaker

discuss personally

Model

| Brand | ABB |

| Model NO. | 36kV/38kV Indoor Vacuum Servo Motor Controlled Switching Circuit Breaker |

| Rated voltage | 38kV |

| Rated normal current | 1250A |

| Rated frequency | 50/60Hz |

| Series | VD4-CS |

Description:

VD4-CS is the unique solution based on new vacuum interrupter technology and an innovative actuation systems up to 38kV, 1250A, 31.5kA and with superior noise-free performances, to support your business needs in reactive power compensation.Noise-free power quality by safe and reliable switching and protection of capacitor banks.

Key benefits:

Key features:

The CB comprises of:

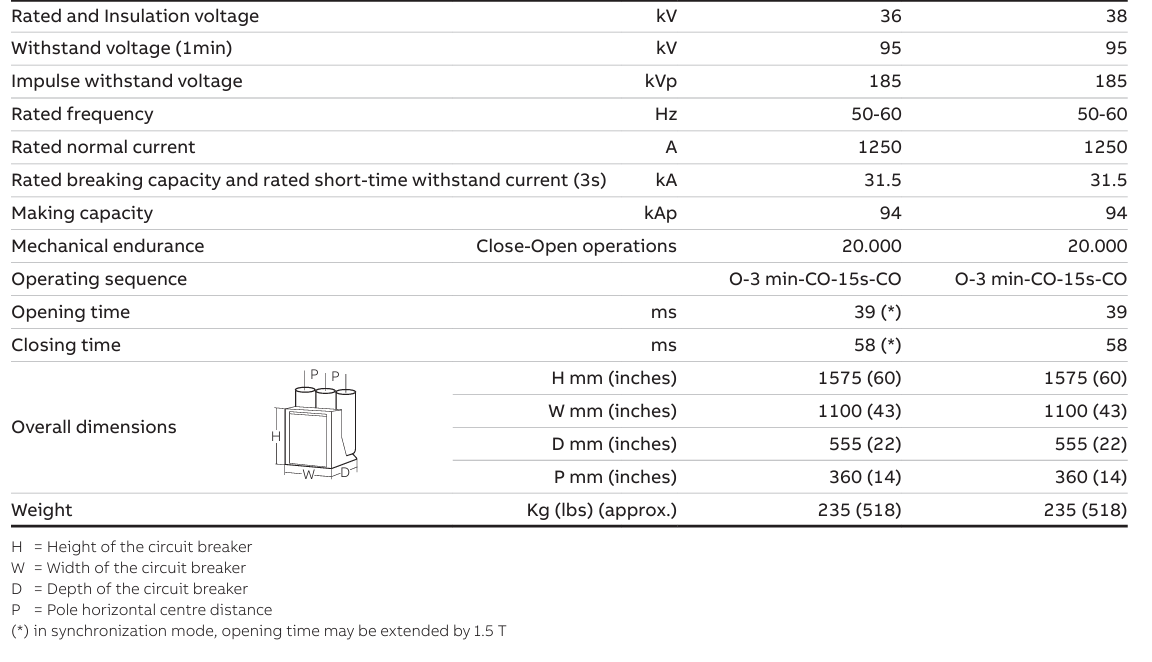

Technical Characteristics:

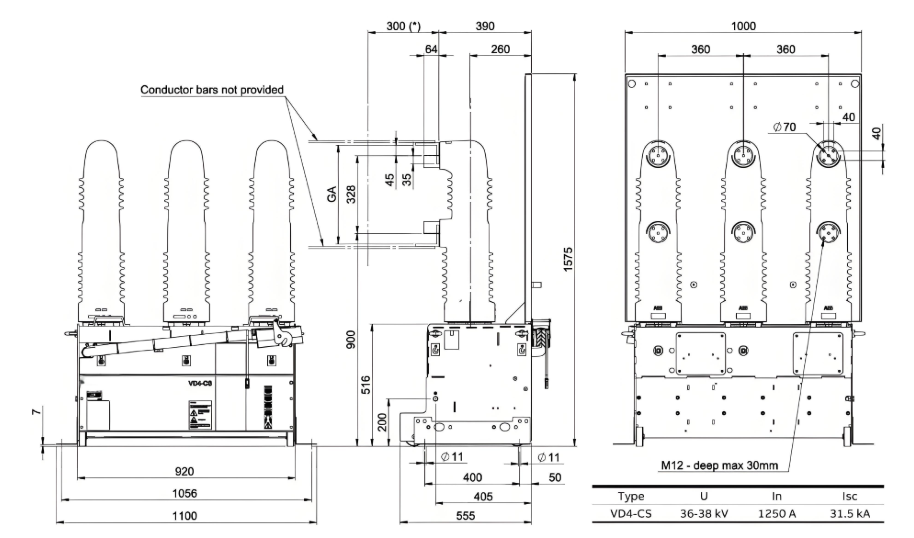

Dimension drawing: