| Brand | ABB |

| Model NO. | Self-powered single-phase recloser for up to 27 kV |

| Rated voltage | 27kV |

| Rated normal current | 200A |

| Rated frequency | 50/60Hz |

| Series | Eagle |

Product Range:Up to 27kV, 200A, 8kA

ABB’s Eagle is a single phase self-powered vacuum interrupting recloser. It can be mounted directly to the pole as a new installation or a replacement to oil filled single-phase reclosers. It can be installed separately on single phase laterals or in a group of three for a three-phase lateral circuit.

Eagle recloser drastically improves the reliability indices for utilities simply by eliminating the sustained interruptions experienced by the customers due to fuse-blowing schemes and momentary interruptions due to fuse-saving schemes. By reducing the number of truck rolls, the utility can save on operational costs and at the same time avoid revenue losses due to outages.

Eagle provides highest interrupting rating among its class with higher BIL (basic insulation level) and continuous current rating providing application from major three-phase feeder laterals to the end-of-line single phase laterals.

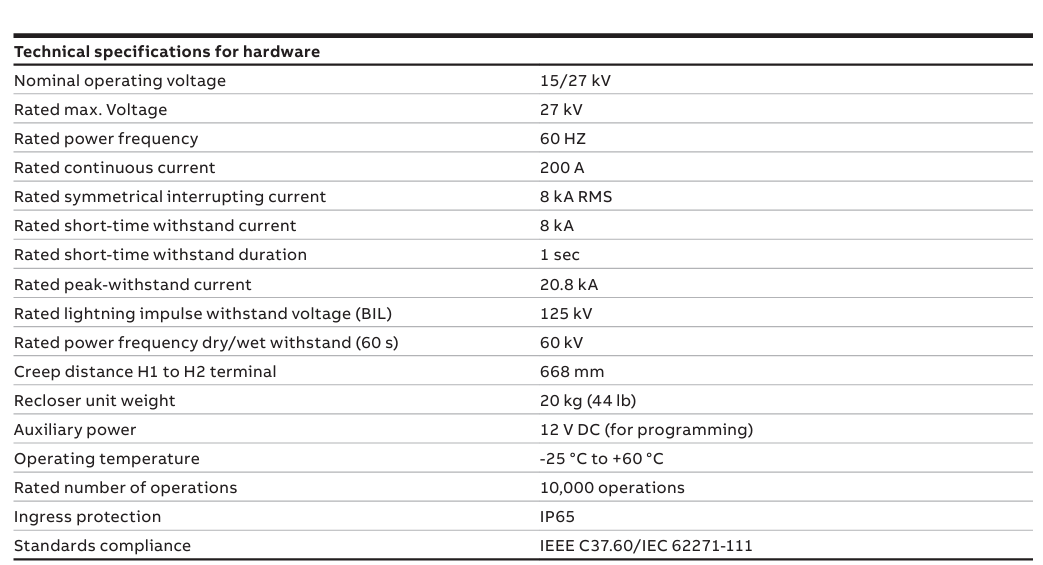

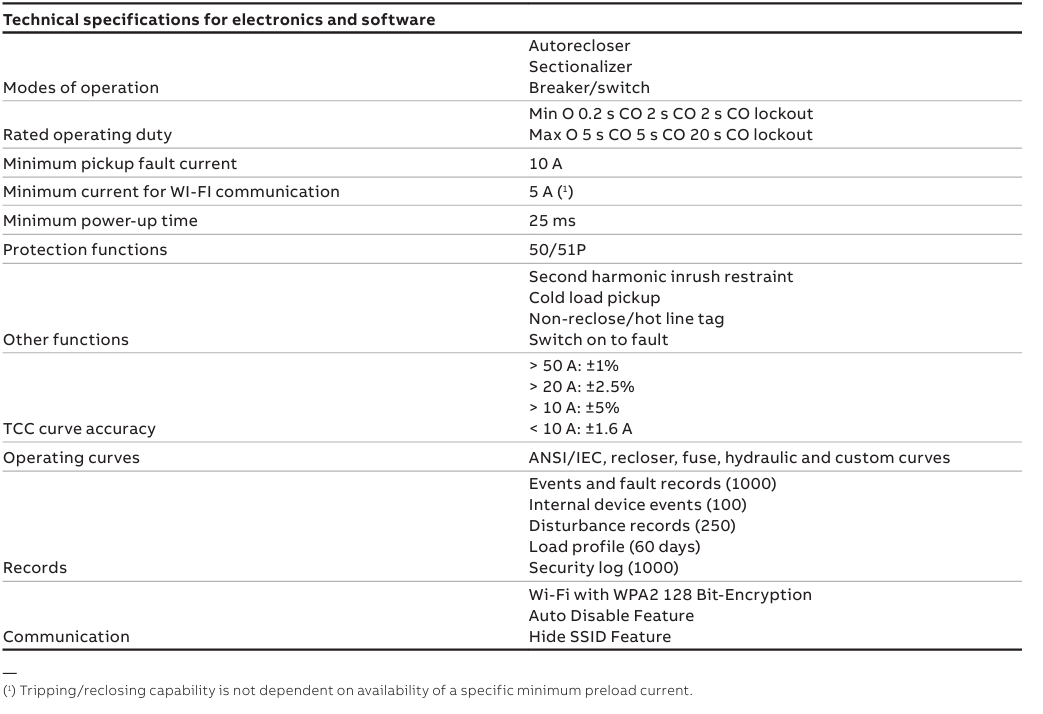

The following technical parameters fully present the product's electrical parameter configurations, mechanical performance parameters, and dimensional details to facilitate precise system integration and application planning.

Key features

Key features highlight the product’s innovative design, high-performance capabilities, and operational advantages, ensuring optimal suitability for diverse industrial and power system requirements.

Key benefits

Key benefits underscore the product’s reliability, efficiency, and cost-effectiveness, delivering tangible value for power distribution and industrial applications.