| Brand | Vziman |

| Model NO. | 2500KVA 11KV Oil-immersed distribution transformer three-phase |

| Rated voltage | 11kV |

| Rated capacity | 2500kVA |

| Series | S |

Description:

Oil immersed transformer ,use our company special calculation and validation procedures to make sure theperformance of products. superior process equipment ,elaborate materialselecting and efficient manufacturing make the transformer have smallvolume,light weight,low loss,low partial discharge,low noise characteristics.

The product is stable,reliable,economic, environmental protection. lt can beapplied to many places such as power plants,transformer substation ,largeindustrial mining and petrochemical enterprise and so on.

Features:

Ultralow no-load loss

Energy saving and great power consuming efficiency

Copper coil winding, strong short circuit resistance ability

Dyn11 coil connection decrease the influences of harmonic wave

Fully sealed structure for maintenance free

Slow insulation aging & longer serving life

Parameters:

Oil-immersed distribution transformer three-phase |

|

Model NO. |

S-2500-11 |

Product classification |

Distribution transformer |

Rated capacity |

2500kVA |

Primary voltage |

11kV |

Secondary voltage |

0.4kV |

Number of phase |

3 |

Number of winding |

2 |

Rated frequency |

50Hz |

Tap changer |

OCTC |

Tap range |

±2×2.5% |

Vector group |

Yd11(400v delta ,11kv star ) |

Cooling system |

ONAN |

No-load loss |

3800+10% |

Load loss |

19000+10% |

Standard |

IEC60076 |

Impedance |

4.75±10% |

Basic insulation level |

75/28kv |

Winding material ( H.V & L.V) |

Copper |

The way the bushing appears |

Porcelain |

Power frequency withstand voltage |

—— |

Lightning impulse |

—— |

The temperature rise—Winding |

—— |

The temperature rise --Top oil |

—— |

Tank color |

—— |

Creepage distance |

—— |

Environmental requirement |

—— |

Transformer structure |

Sealed |

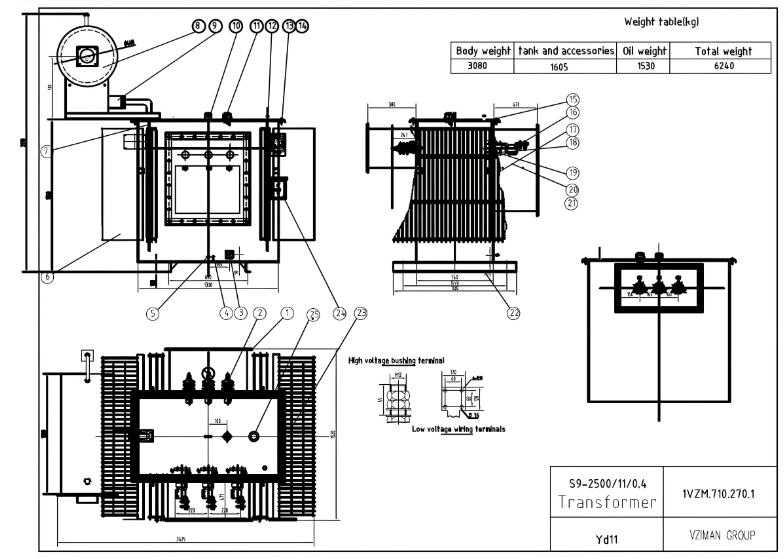

External dimensions:

Size |

2425mm×1520mm×2170mm |

Weight |

3080KG |

Environmental requirement:

Max. ambient temperature |

|

Altitude |

Product show:

What are the structural characteristics of oil-immersed distribution transformers?

Oil-Immersed: It means that the iron core and windings of the transformer are immersed in insulating oil, and the oil plays a dual role of cooling and insulation.

Distribution Transformer: It is used to convert high-voltage electrical energy into low-voltage electrical energy for users' use.

Three-Phase: Usually, it means that the transformer has three independent windings and is applicable to three-phase alternating current systems.

Iron Core: It is usually made by laminating high-quality silicon steel sheets, featuring low loss and low noise.

Windings: The primary winding and the secondary winding are usually wound with copper wires, possessing excellent electrical conductivity and mechanical strength.

Insulating Oil: The inside of the transformer is filled with insulating oil. The oil not only plays a cooling role but also provides good insulation performance.

Oil Tank: The iron core and windings of the transformer are installed in the oil tank. The oil tank is usually made of steel plates and has good sealing performance.

Cooling System: Depending on the power level, oil-immersed transformers can adopt natural cooling, air cooling or forced oil circulation cooling methods.

Bushing: The high-voltage and low-voltage leads are led out through the bushing. The bushing has good insulation performance to ensure safe operation.