| Brand | Vziman |

| Model NO. | 100KVA Step Up All Copper Three Phase Dry Type Distribution Transformer |

| Rated capacity | 100kVA |

| Voltage grade | 20KV |

| Series | SC(B) |

Description:

Dry-type transformers rely on natural or forced air cooling to dissipate the heat generated during operation. Proper ventilation and airflow around the transformer are essential to prevent overheating and maintain optimal efficiency.

Dry-type transformers are less susceptible to environmental factors than oil-immersed transformers, but certain environmental conditions still need to be taken into account.

The installation site should have protection against exposure to moisture, dust, corrosive agents, or other contaminants that could potentially degrade the transformer's insulation and components.

In harsh environments, such as coastal areas or industrial settings, additional protection measures, such as weatherproof enclosures or specialized coatings, may be necessary.

Proper electrical connections, including the primary and secondary windings, as well as the grounding of the transformer, must be carried out according to relevant electrical codes and manufacturer's specifications.

Feature:

The magnetic core has a miter step joint to ensure optimum performance and minimum sound levels by using step lap technology.

Windings are cast under vacuum with epoxy resin. Transient analysis tests have been performed to verify the electrical stress distribution.

Air-cooling system adopts top-blowing cross flow fan, which has the characteristics of low noise, high wind pressure, beautiful look, etc.

Intelligent temperature controller improves the safety and reliability of the transformer.

Supply various Enclosure options in IP20, IP23, etc.

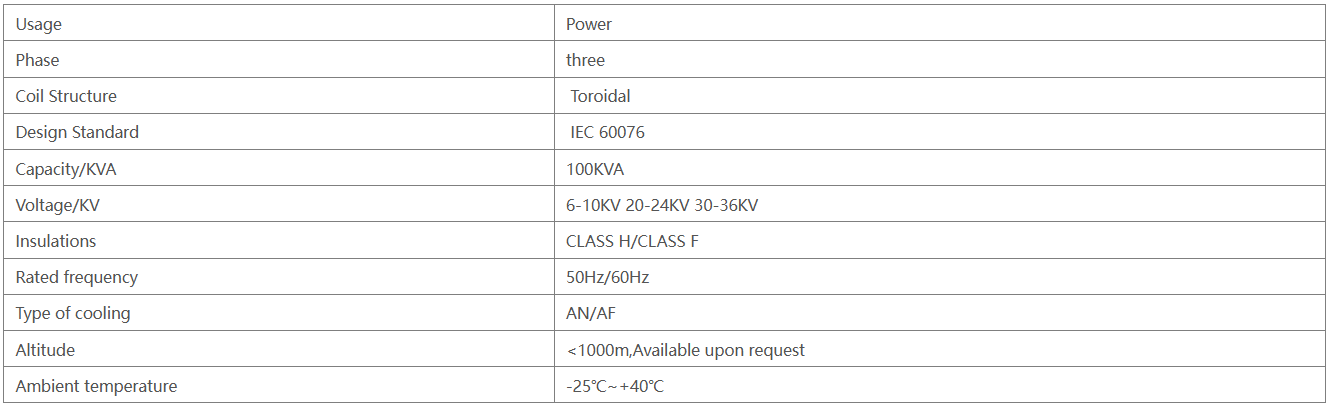

Parameter:

Installation Location:

Installed in places without fire, explosion hazard, serious pollution, chemical corrosion and cluster vibration, indoor or outdoor.

Supply Ability:500 Set/Sets per Month.

Customized Service:

E2 Environmental Class.

C2 Climate Class.

F1 Fire Resistance Class.

Product Advantages:

Vacuum-Casting

Our product is manufactured with vacuum casting process using a metal pattern, producing a thick resin layer with a smooth surface.

Partial Discharge Free

Lower partial discharge characteristics.

All units are subjected to partial discharge test.

Voltage that is twice that of the operating system is applied to ensure safety.

Partial discharge is less than 10 pC.

Shop Test Items.

Routine test:

Routine test is a must test for all transformers in our workshop.

Type test (as requested).

Lightning impulse test.

Temperature-rise test.

Measurement of sound level.

What is a step-up all-copper three-phase dry-type distribution transformer?

Definitions and Characteristics:

Voltage Boosting: It means that a transformer converts the input low-voltage electrical energy into high-voltage electrical energy.

All-Copper: The windings of the transformer are all made of copper wires, which possess excellent electrical conductivity and mechanical strength.

Three-Phase: It indicates that the transformer has three independent windings and is applicable to three-phase alternating current systems.

Dry-Type: It means that the transformer does not use a liquid cooling medium (such as transformer oil), and usually adopts natural air cooling or forced air cooling.

Working Principle:

Input Voltage: The low-voltage power source is applied to the transformer through the primary winding.

Generating Magnetic Field: The current in the primary winding generates an alternating magnetic field in the iron core.

Transferring Magnetic Field: The alternating magnetic field is transferred to the secondary winding through the iron core.

Inducing Electromotive Force: The alternating magnetic field induces an electromotive force in the secondary winding, generating a high-voltage output voltage.

Output Voltage: The secondary winding outputs the required high-voltage electrical energy for the load to use.