What is are the Types of Single Phase Induction Motors ?

What is are the Types of Single Phase Induction Motors ?

Single phase induction motor definition

A single-phase induction motor is an electric motor that operates in a single AC phase and requires additional mechanisms to initiate rotation.

According to the extra flux single-phase induction motor can be divided into

Split phase induction motor

Capacitance starts induction motor

Capacitor start Capacitor run induction motor

Permanent shunt capacitor (PSC) motor

Shaded pole induction motor

Separate phase operation

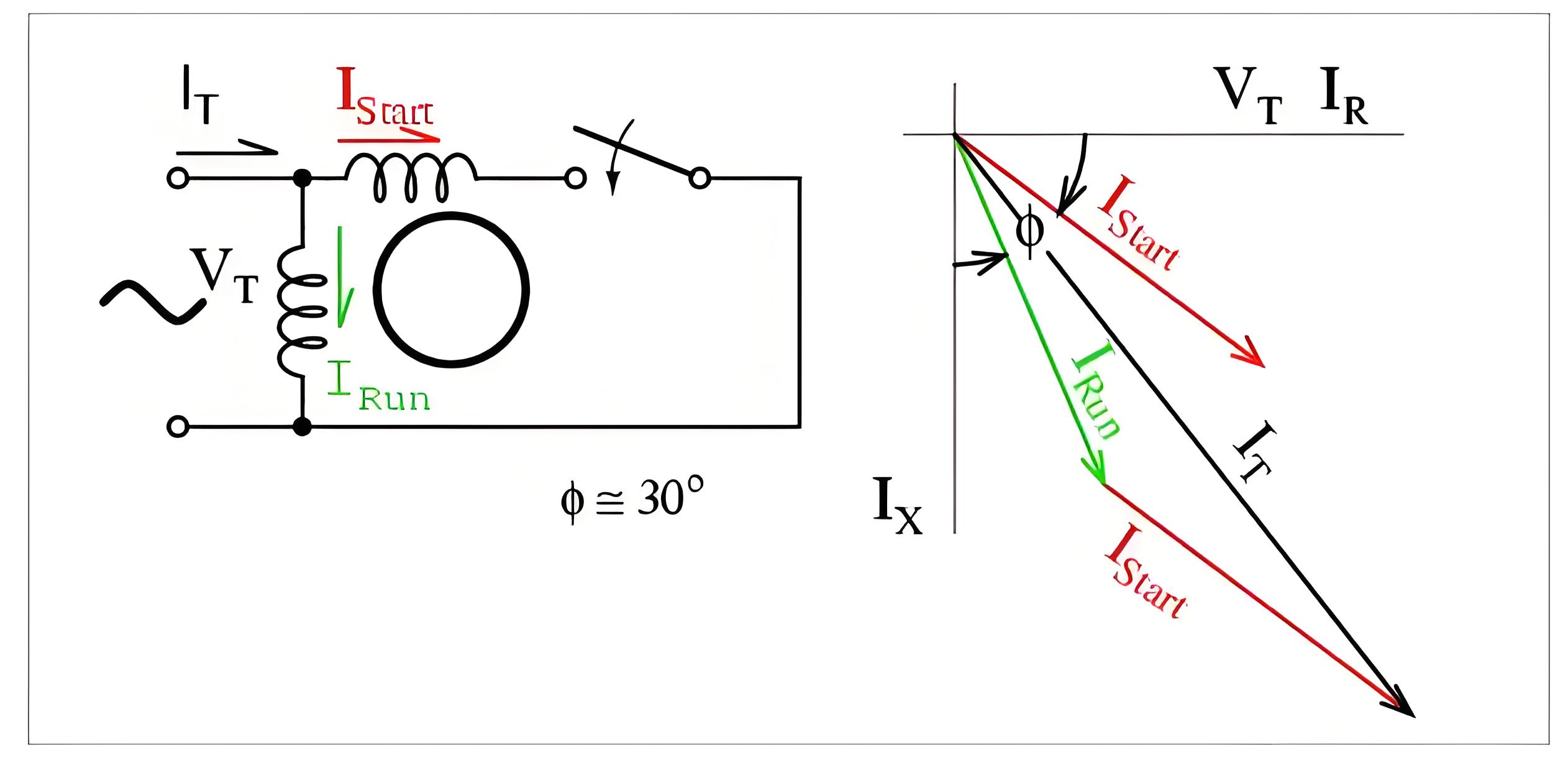

The split-phase motor uses an auxiliary winding with high resistance and a centrifugal switch that disengages at 75-80% of the synchronous speed to facilitate motor start-up.

Irun is the current flowing through the main or running winding,

Istart is the current flowing in starting winding,

VT is the supply voltage.

In high resistance windings, the current is closely aligned with the voltage. In contrast, in high induction windings, the current lags behind the voltage significantly.

The starting windings are highly resistive, so the current flowing in the starting windings lags behind the applied voltage by a very small Angle, while the running windings are highly inductive in nature, so the current flowing in the running windings lags behind the applied voltage by a large Angle.

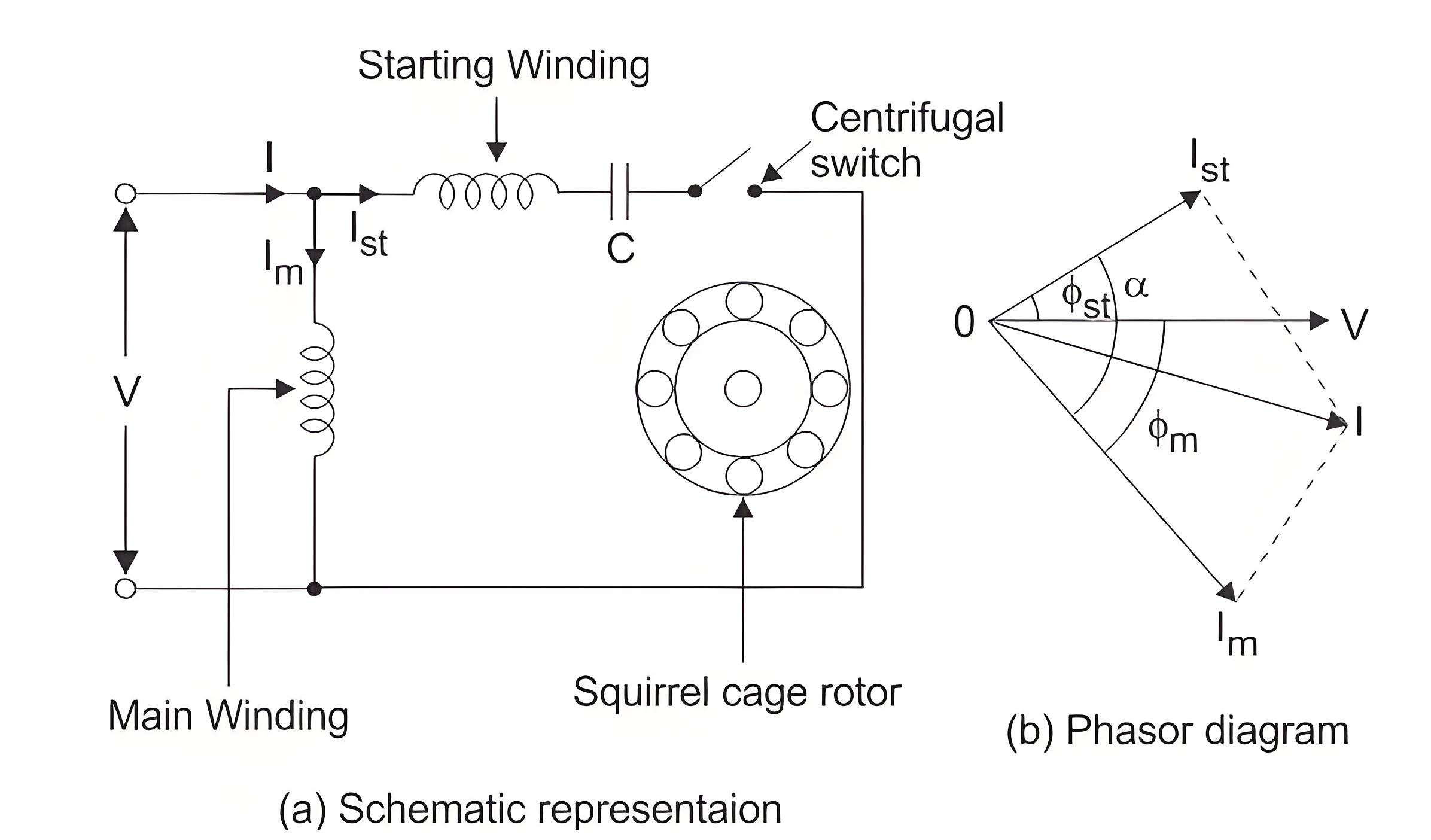

Capacitor up and running

These motors use capacitors to generate the necessary phase difference, which creates a strong starting torque and improves the power factor during operation.

Advantages of permanently separating capacitors

PSC motors maintain a constant capacitor connection, eliminating the need to start switches and increasing efficiency.

Mask characteristic

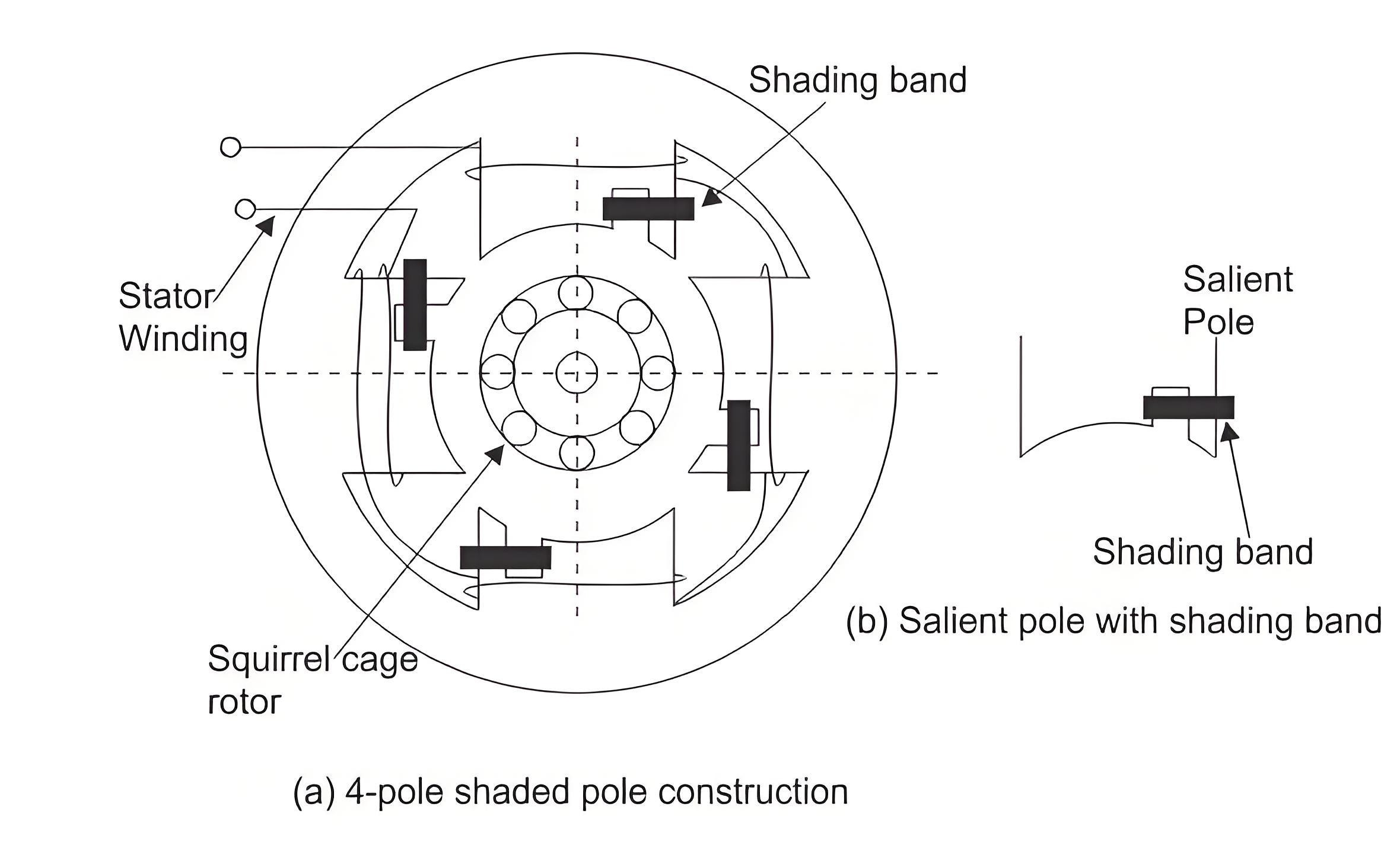

Covered pole motors use copper rings to sense phase shifts in a portion of the magnetic poles, resulting in a rotating magnetic field suitable for small, low-power devices.

Advantages and disadvantages of shaded pole motor

Very economical and reliable.

Because there is no centrifugal switch, the structure is simple and strong.

Disadvantages of shaded pole induction motor

Low power factor.

The starting torque is poor.

Due to the presence of copper strip, copper loss is high, so the efficiency is very low.

Speed reversal is also difficult and expensive because it requires another set of copper rings.

The Electricity Encyclopedia is dedicated to accelerating the dissemination and application of electricity knowledge and adding impetus to the development and innovation of the electricity industry.