Armature Winding

Armature winding definition

The armature winding in an alternator is the arrangement of coils to generate electricity and is essential to its operation.

Type of armature winding

Single-phase armature winding

Single-phase armature windings can be centralized or distributed.

Centralized armature winding

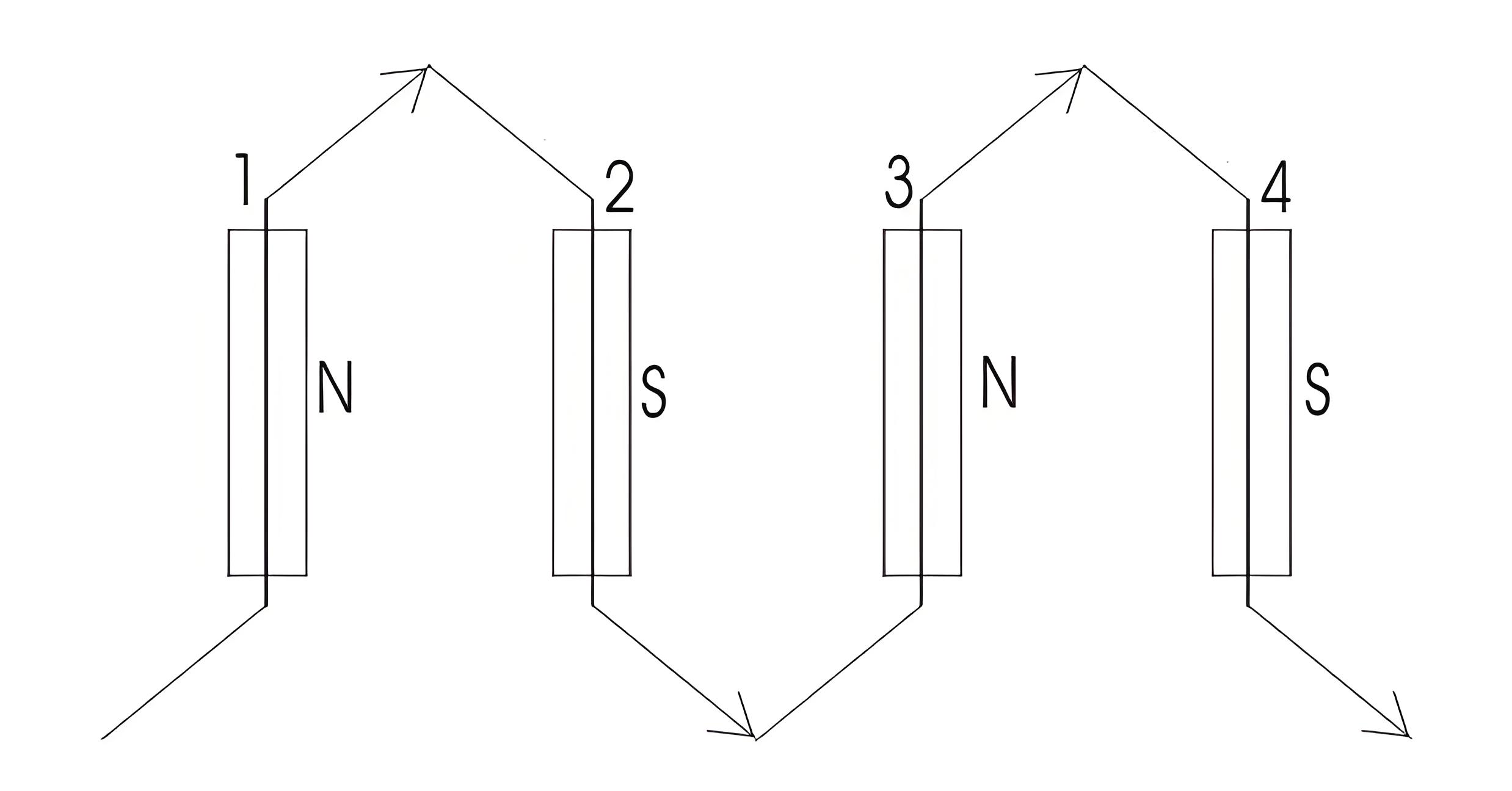

When the number of slots on the armature equals the number of poles in the machine, the central winding is used. This winding type provides maximum output voltage, but is not always fully sinusoidal. The simplest single-phase winding is shown in Figure 1 below. Here, number of poles = number of slots = number of coil sides. Here, one coil side is located in a slot under one pole and the other coil side is located in the other slot under the next pole. The electromotive force induced on one coil side is added to the electromotive force on the adjacent coil side.

Distributed armature winding

To obtain a smooth sinusoidal electromotive force wave, the conductor is placed in several slots under the unipole. This kind of armature winding is called distributed winding. Although the distributed armature winding in an alternator reduces the electromotive force, it is still very usable for the following reasons.

It can also reduce the harmonic electromotive force, thus improving the waveform.

It also reduces armature reactions.

The evenly distributed conductors contribute to better cooling.

Because the conductors are distributed in slots on the periphery of the armature, the magnetic core is fully utilized.

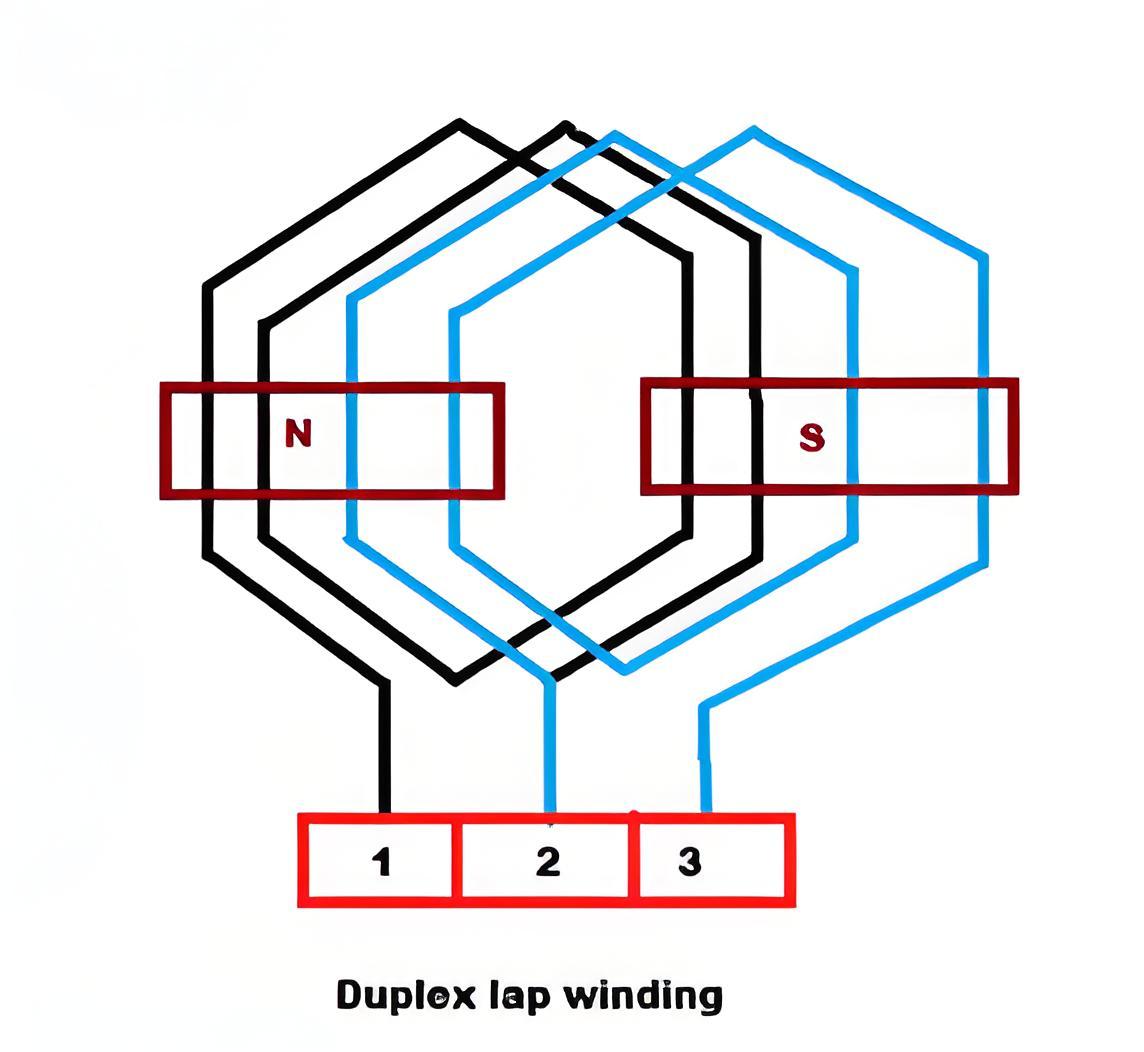

Alternator lap winding

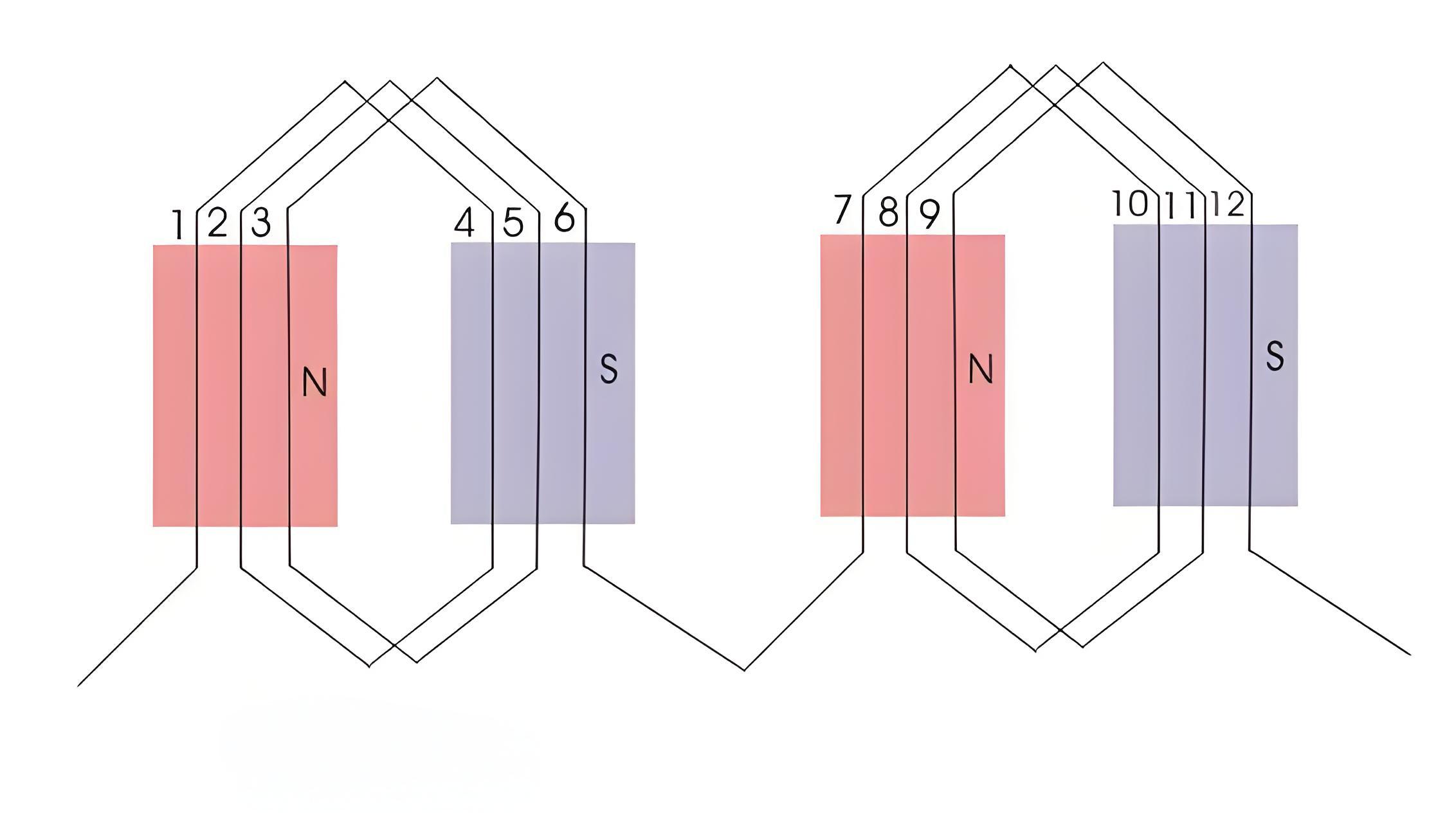

The 4-pole, 12-slot, 12-conductor (one conductor per slot) full-pitch lap winding of the alternator is shown below.

The back pitch of the winding is equal to the number of conductors per pole, that is, = 3, and the front pitch is equal to the back pitch minus 1.

Wave winding of alternator

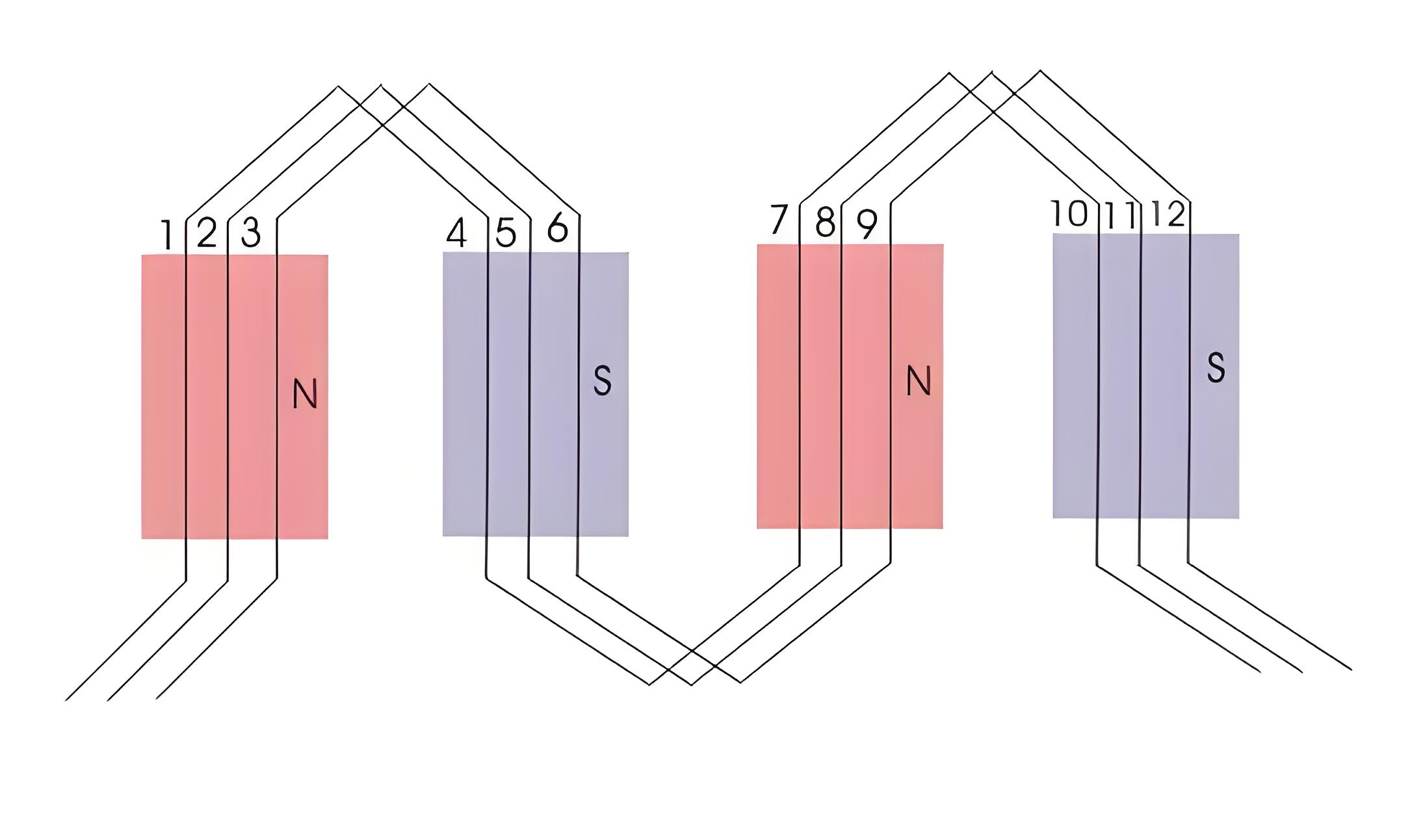

The waveform winding of the same machine, that is, four poles, 12 slots, 12 conductors, is shown in Figure e below. Here, both the back and front spacing are equal to a number of conductors per pole.

Polyphase armature winding

Used in polyphase alternators to ensure balanced performance and efficient power generation between different phases.

The Electricity Encyclopedia is dedicated to accelerating the dissemination and application of electricity knowledge and adding impetus to the development and innovation of the electricity industry.