What is Induction Motor Rotor?

What is Induction Motor Rotor?

Induction motor rotor definition

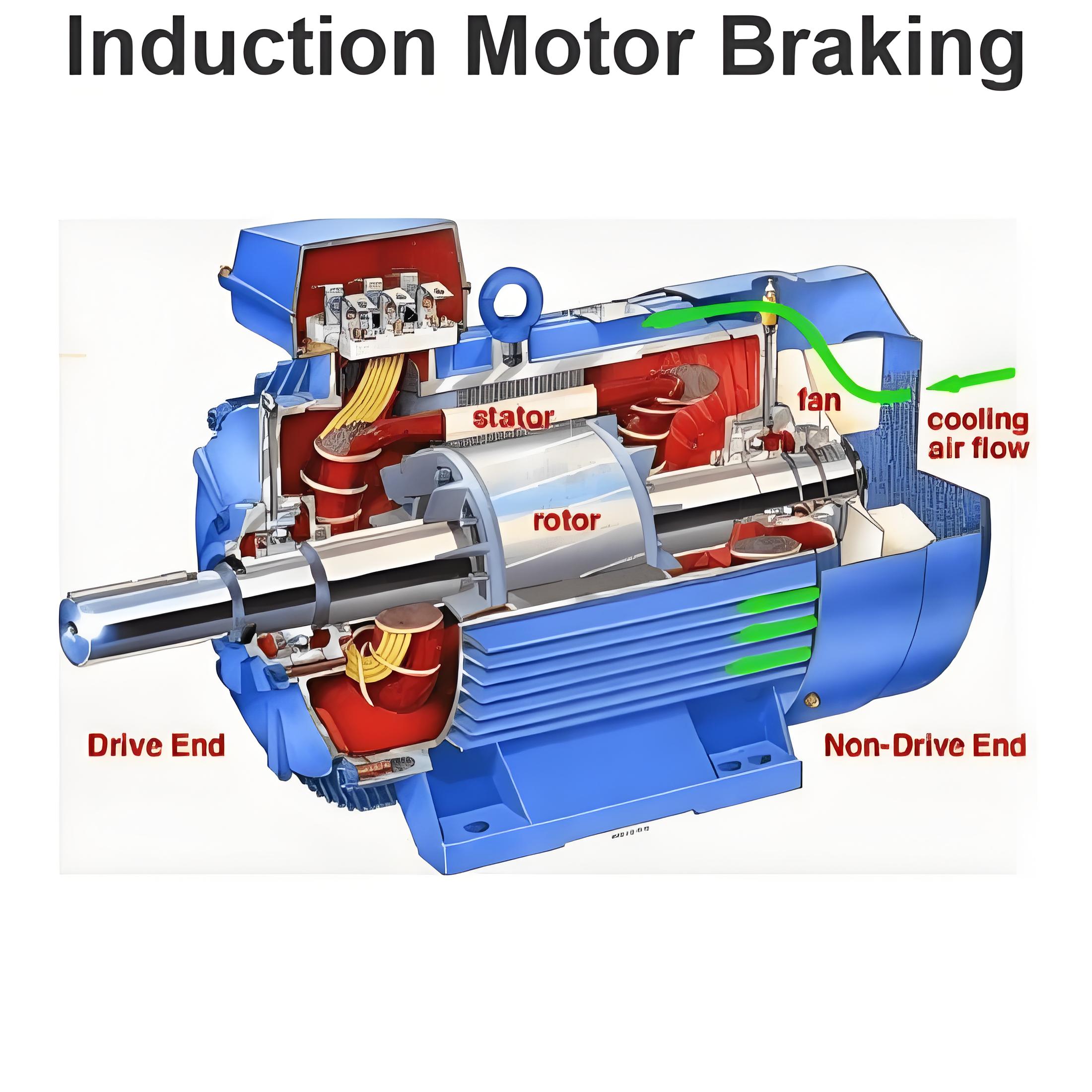

The rotor is a rotating part of a motor in which current is induced by a rotating magnetic field.

Type of rotor

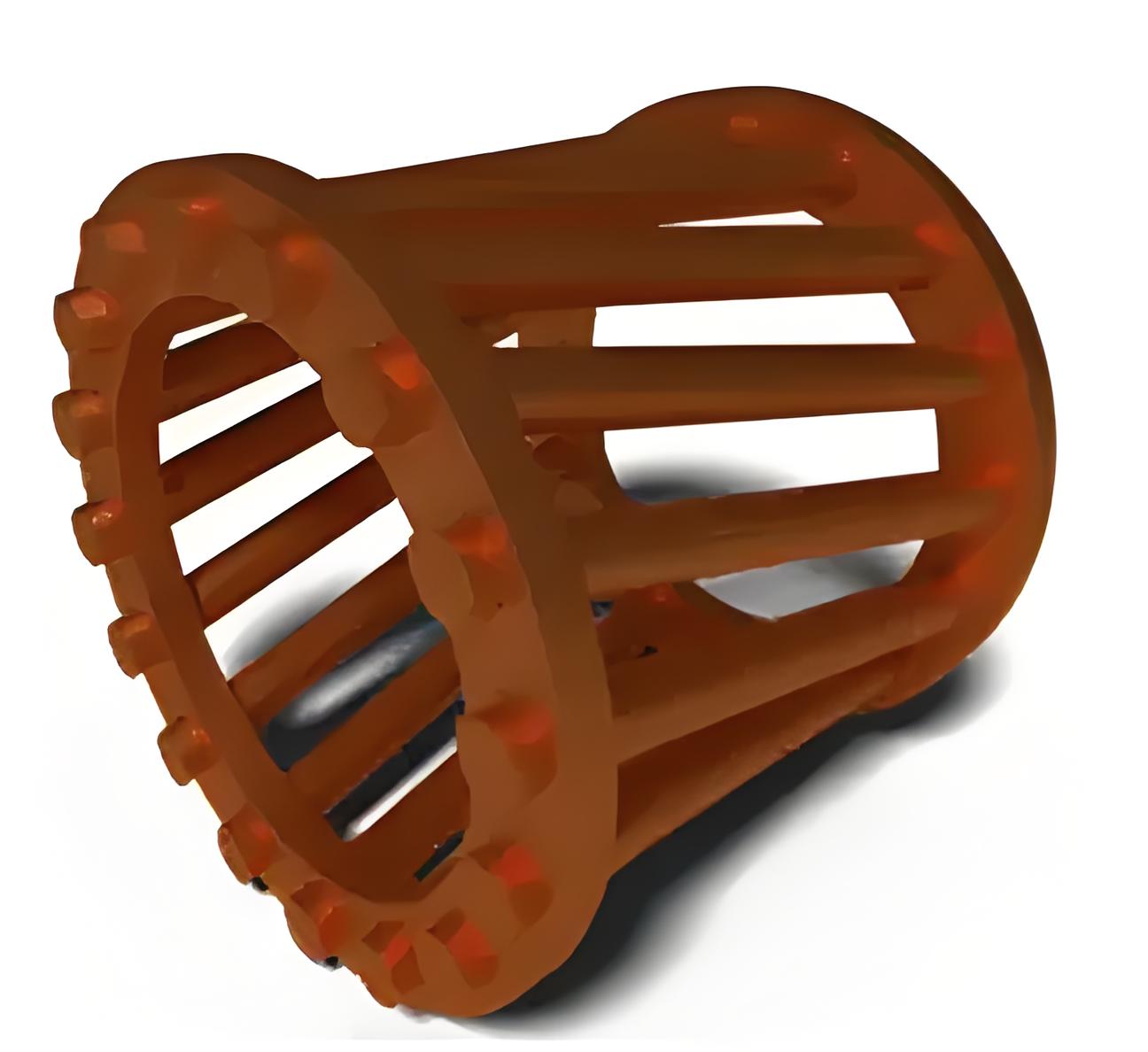

Squirrel cage rotor

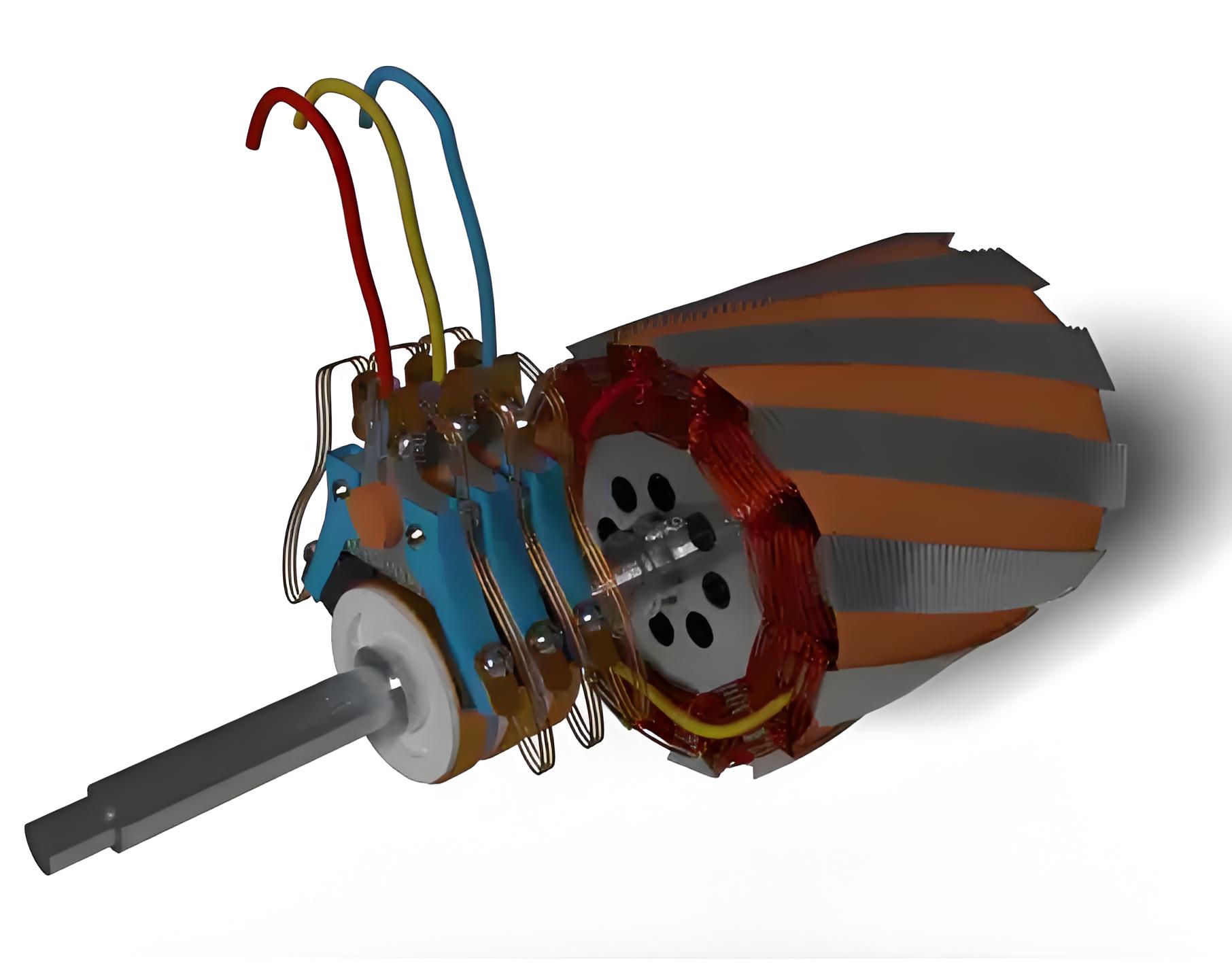

Wound rotor

Squirrel cage rotor features

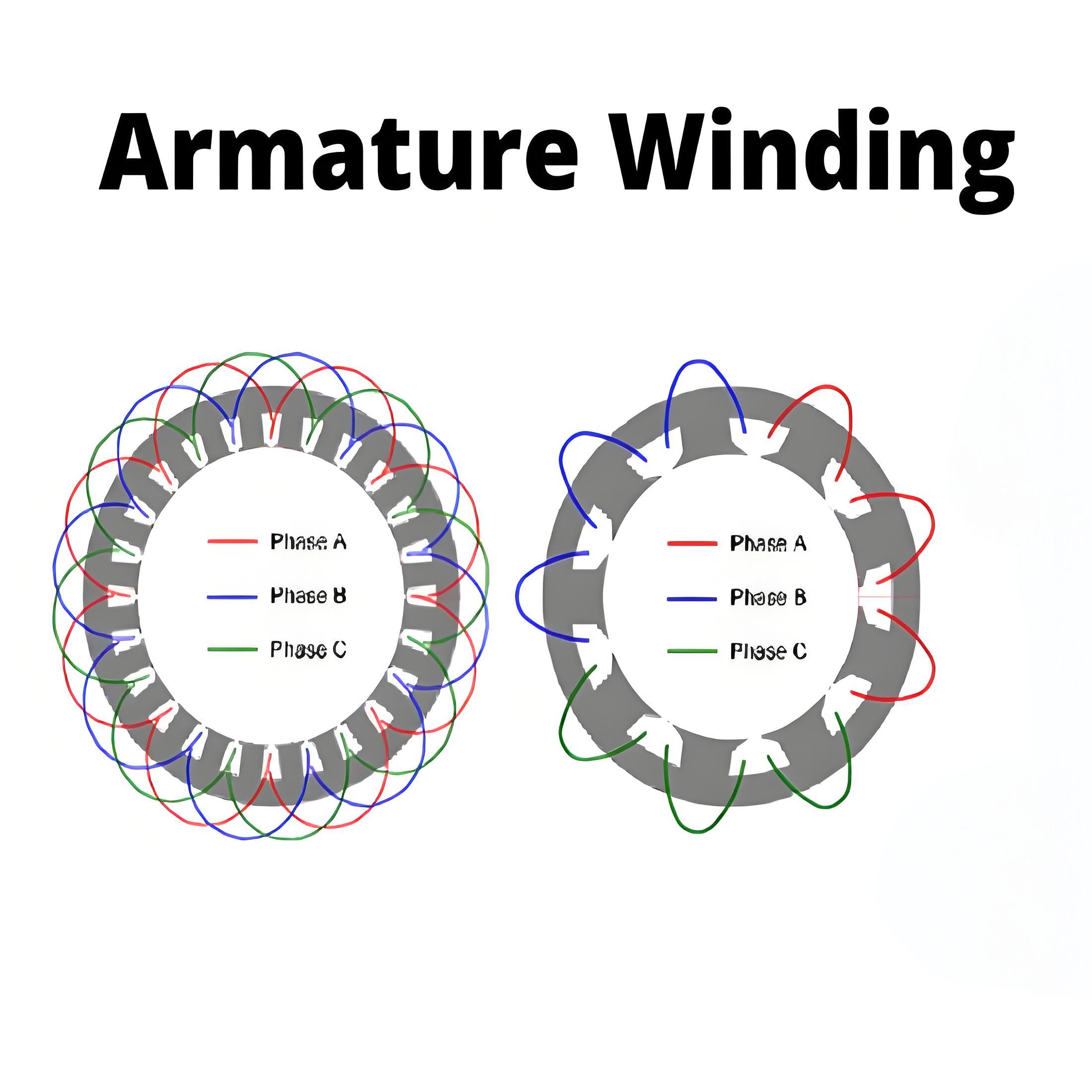

In this type of rotor, the rotor winding consists of conductors that are embedded in semi-closed slots in the form of copper or aluminum strips in the laminated rotor core. In order to facilitate the formation of a closed path in the rotor circuit, both sides of the rotor rod are shorted through the end ring.

Characteristics of the squirrel cage rotor

This type of rotor does not have a definite number of poles, but through induction, the rotor will automatically sense the same number of stator poles. Therefore, for the squirrel cage rotor in order to increase the starting torque, we need to increase the rotor resistance by adding a resistor in series with the rotor winding. However, this is not possible in squirrel cage rotors because their rotor rod is short-circuited by the end ring. Therefore, the squirrel cage rotor has good running performance, but poor starting performance.

Disadvantages of the squirrel cage rotor

Low starting torque

High starting current

Power factor difference

Skewed rotor rod

Skewed rotor rods increase their length, which increases their resistance and improves starting torque. Resistance is proportional to length, so a longer rod means higher resistance and better torque.

Winding rotor or slip-ring rotor

This type of rotor is also made of laminated cold-rolled grain-oriented silicon steel to reduce eddy current losses and hysteresis losses. The rotor windings are distributed at short intervals to obtain a sinusoidal electromotive force output.

Induction motors are not possible when the number of stator and rotor poles is not equal, and this type of rotor does not automatically respond to changes in the number of stator poles. Therefore, the number of rotor poles must equal the number of stator poles.

If the rotor is equipped with a 3-phase winding; Whether the stator windings are star connections or triangle connections, the rotor windings must be star connections.

Features of winding rotor or slip-ring rotor

The main difference between a squirrel cage rotor and a wound rotor is the presence of a slip ring in the wound rotor, so it is also called a slip ring rotor. The three terminals connecting the star rotor winding are extracted and connected to the external resistor through the slip ring.

Slip rings are made of high-resistance materials, such as phosphor bronze or brass. Brush contacts are used to connect the rotor windings to the external circuit, and brushes are made of carbon or copper material, but carbon is preferred due to its self-lubricating properties. Therefore, the use of carbon brush friction loss is less.

In order to increase the starting torque, an external resistor is used. The external resistor also limits the starting current consumed by the motor at startup. As a result, the power factor is improved.

The Electricity Encyclopedia is dedicated to accelerating the dissemination and application of electricity knowledge and adding impetus to the development and innovation of the electricity industry.