What is Armature Reaction in DC Machine?

What is Armature Reaction in DC Machine?

Armature reaction definition

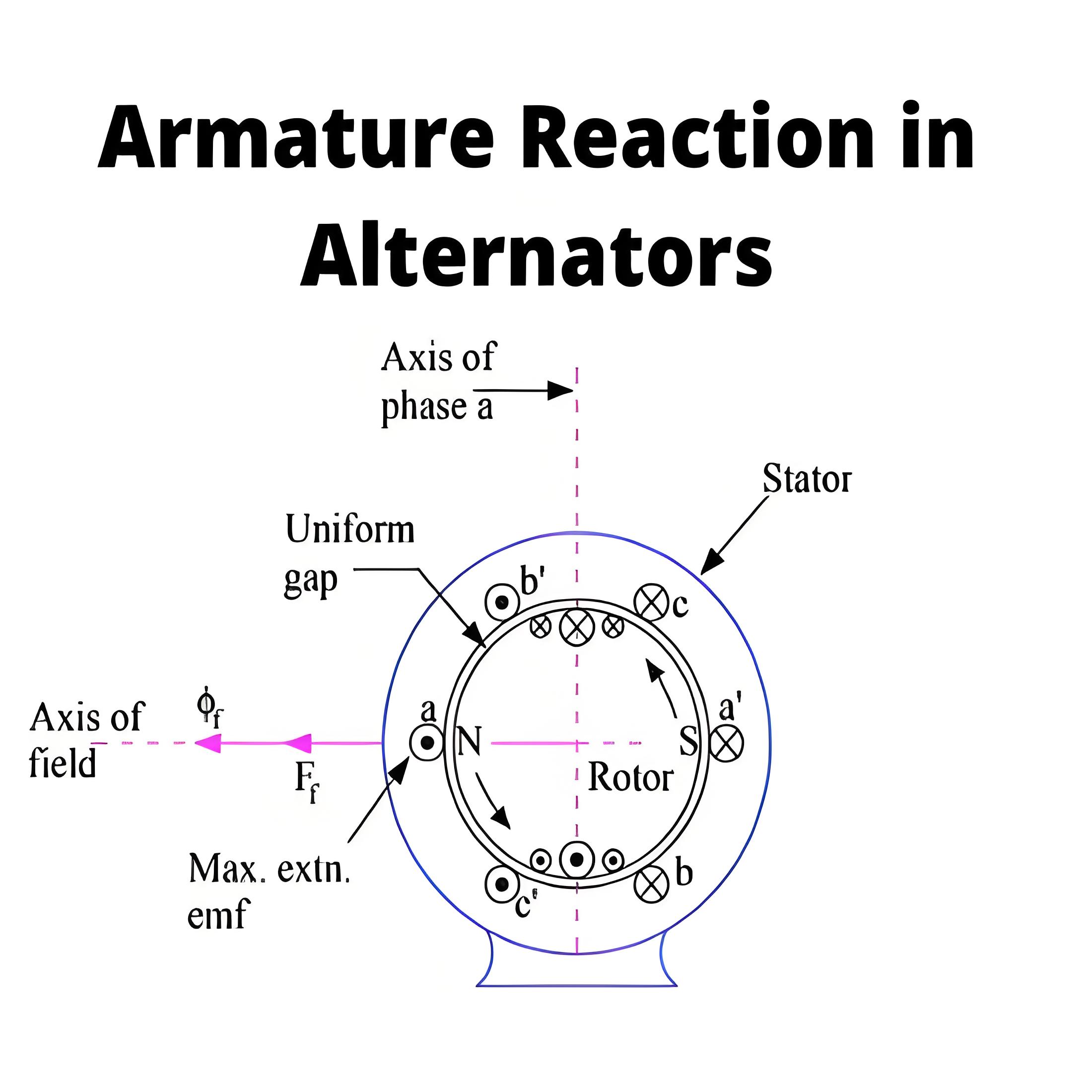

The armature reaction in a DC motor is the effect of the armature magnetic flux on the main magnetic field, changing its distribution and intensity.

Cross magnetization

Cross-magnetization due to the armature current affects the magnetic field by moving the magnetic neutral axis, resulting in efficiency problems.

Brush Shift

A natural solution to the problem appears to shift the brushes along the direction of rotation in generator action and against the direction of rotation in motor action, this would result into a reduction in air gap flux. This will reduce the induced voltage in generator and would increase the speed in motor. The demagnetizing mmf (magneto motive force) thus produced is given by:

Where,

Ia = armature current,

Z = total number of conductors,

P = total number of poles,

β = angular shift of carbon brushes (in electrical Degrees).

Brush shift has serious limitations, so the brushes have to be shifted to a new position every time the load changes or the direction of rotation changes or the mode of operation changes. In view of this, brush shift is limited only to very small machines. Here also, the brushes are fixed at a position corresponding to its normal load and the mode of operation. Due to these limitations, this method is generally not preferred.

Inter Pole

The limitation of brush shift has led to the use of inter poles in almost all the medium and large sized DC machines. Inter poles are long but narrow poles placed in the inter polar axis. They have the polarity of succeeding pole (coming next in sequence of rotation) in generator action and proceeding (which has passed behind in rotation sequence) pole in motor action. The inter pole is designed to neutralize the armature reaction mmf in the inter polar axis. Since inter poles are connected in series with armature, the change in direction of current in armature changes direction of inter pole.

This is because the direction of armature reaction mmf is in the inter polar axis. It also provides commutation voltage for the coil undergoing commutation such that the commutation voltage completely neutralizes the reactance voltage (L × di/dt). Thus, no sparking takes place.

Inter polar windings are always kept in series with armature, so inter polar winding carries the armature current; therefore works satisfactorily irrespective of load, the direction of rotation or the mode of operation. Inter poles are made narrower to ensure that they influence only the coil undergoing commutation and its effect does not spread to the other coils. The base of the inter poles is made wider to avoid saturation and to improve response.

Compensating Winding

Commutation problem is not the only problem in DC machines. At heavy loads, the cross magnetizing armature reaction may cause very high flux density in the trailing pole tip in generator action and leading pole tip in the motor action.

Consequently, the coil under this tip may develop induced voltage high enough to cause a flash over between the associated adjacent commutator segments particularly, because this coil is physically close to the commutation zone (at the brushes) where the air temperature might be already high due to commutation process.

Compensating windings major drawbacks

In large machines subject to heavy overloads or plugging

In small motors subject to sudden reversal and high acceleration.

The Electricity Encyclopedia is dedicated to accelerating the dissemination and application of electricity knowledge and adding impetus to the development and innovation of the electricity industry.