Loss evaluation in transformers based on IEC 60076

I. Definitions of Losses in IEC 6007

IEC 60076-1 (General Requirements) and IEC 60076-7 (Loading Guidelines) specify two core types of losses:

No-load Loss (P0)

Definition: Losses measured when the primary winding is energized at rated voltage and the secondary winding is open-circuited (dominated by core losses).

Test Conditions

- Measured at rated frequency and voltage (typically sinusoidal power frequency).

- Corrected to reference temperature (75°C for oil-immersed transformers, 115°C for dry-type).

Load Loss (Pk)

Definition: Losses measured when the secondary winding is short-circuited and rated current flows through the primary winding (dominated by copper losses).

Test Conditions:

- Measured at rated current and frequency.

- Corrected to reference temperature (75°C for oil-immersed; varies for dry-type based on insulation class).

II. Testing and Calculation of Losses

No-load Loss Test (IEC 60076-1 Clause 10)

Method

- Direct measurement using a power analyzer (instrument losses must be subtracted).

- Test voltage: rated voltage ±5%, with the lowest value used.

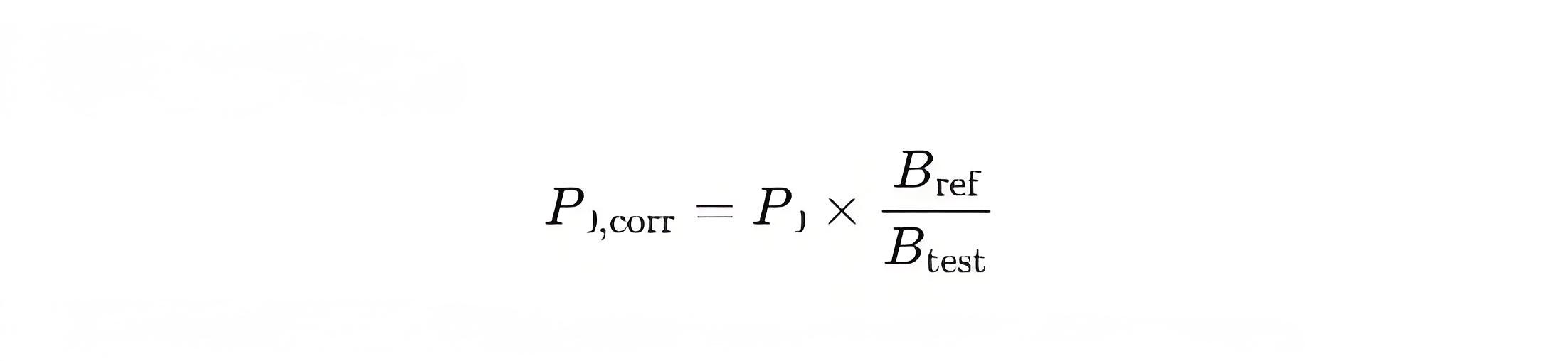

Temperature Correction Formula:

Bref: Flux density at reference temperature; B test : Measured flux density.

2. Load Loss Test (IEC 60076-1 Clause 11)

Method:

- Measured during short-circuit impedance testing.

- Test current: rated current; frequency deviation ≤ ±5%.

Temperature Correction Formula (for copper windings)

Tref: Reference temperature (75°C); T test : Winding temperature during testing.

Key Parameters and Tolerances

Loss Tolerances (IEC 60076-1 Clause 4.2):

- No-load loss: +15% allowed (measured value must not exceed guaranteed value).

- Load loss: +15% allowed (measured value must not exceed guaranteed value).

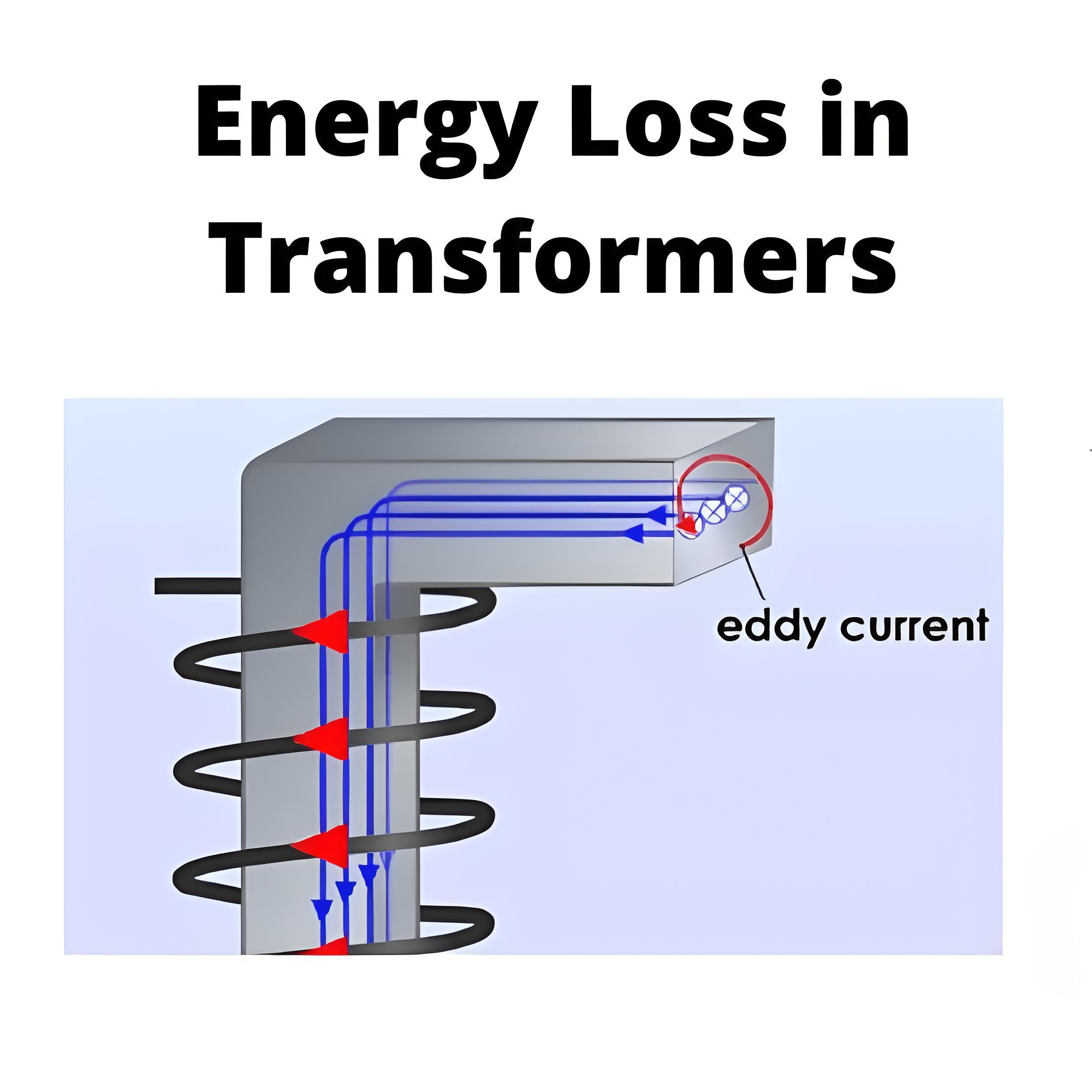

Stray Losses:

Losses caused by leakage flux in structural components, evaluated via high-frequency component separation or thermal imaging.

Energy Efficiency Classes and Loss Optimization

Per IEC 60076-14 (Energy Efficiency Guidelines for Power Transformers):

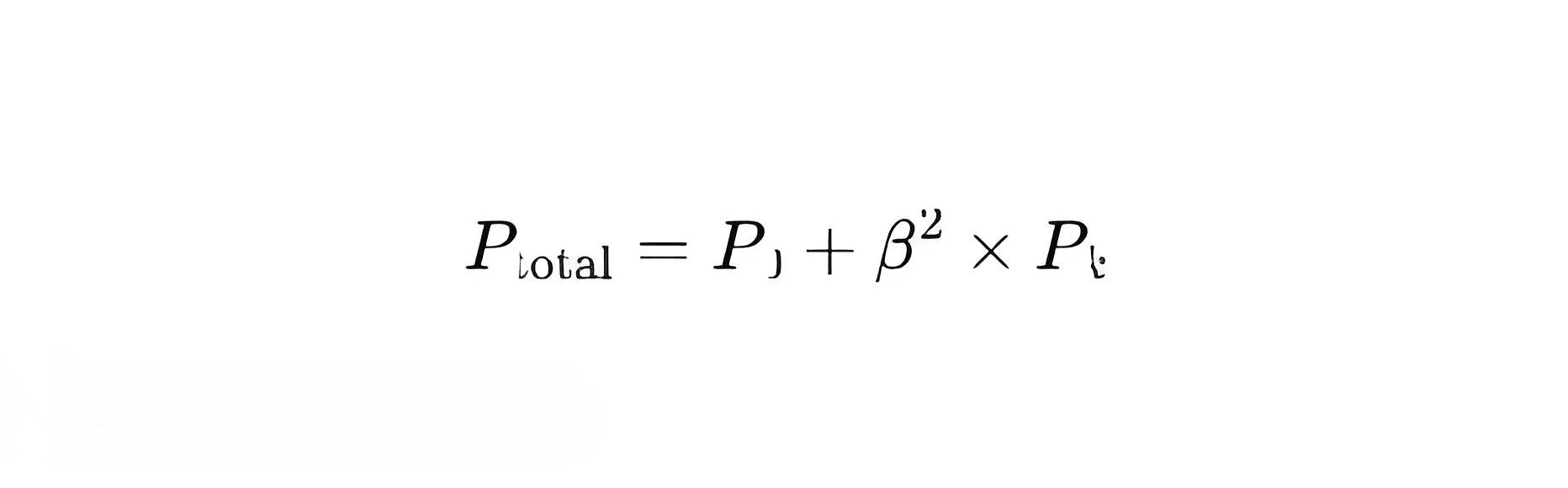

Total Losses (P total):

β: Load ratio (actual load / rated load).

Efficiency Classes (e.g., IE4, IE5) require total losses reduced by 10%~30%, achieved via:

- High-permeability silicon steel (reduces no-load losses).

- Optimized winding design (minimizes eddy current losses).

Practical Application Example

Case: 35kV Oil-Immersed Transformer (IEC 60076-7)

Rated Parameters:

- Capacity: 10 MVA

- Guaranteed no-load loss: 5 kW

- Guaranteed load loss: 50 kW (at 75°C).

Test Data:

No-load loss: 5.2 kW (within +15% tolerance → 5.75 kW limit).

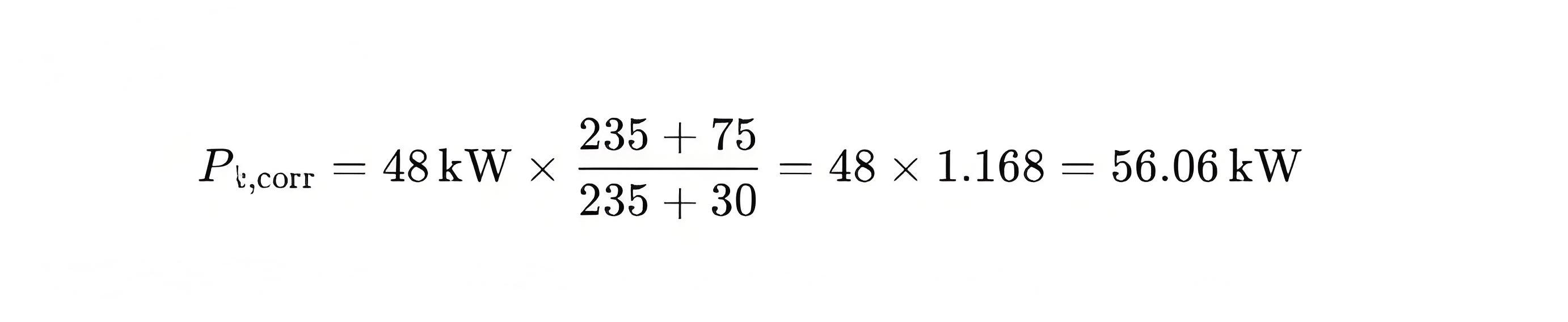

Load loss (tested at 30°C):

Conclusion: Load loss exceeds tolerance? Verify against 50 × 1.15 = 57.5 kW.

VI. Common Issues and Considerations

Ambient Temperature:

Tests must be conducted between -25°C to +40°C; corrections required outside this range.

Harmonic Losses:

Evaluate additional harmonic losses under non-sinusoidal loads per IEC 60076-18.

Digital Testing:

Use IEC 61869-calibrated sensors for accuracy.