Technical Explanation of Sulfur Hexafluoride (SF₆) Circuit Breakers and Gas Liquefaction Challenges

SF₆ circuit breakers, which use sulfur hexafluoride gas—known for its excellent arc-quenching and insulating properties—as the arc-extinguishing medium, are widely applied in power systems. These breakers are suitable for frequent operations and scenarios requiring high-speed interruption. In China, SF₆ circuit breakers are basically used for voltage levels of 110kV and above. However, due to the physical properties of SF₆ gas, it may liquefy under certain temperature and pressure conditions, causing the density of SF₆ gas in the circuit breaker tank to decrease. When the density drops to a certain level, the circuit breaker will trigger a protection lockout. In some regions of China, such as Inner Mongolia, Northeast China, Xinjiang, and Tibet, where the ambient temperature can reach -30°C or even lower in winter, the phenomenon of lockout caused by SF₆ gas liquefaction occurs from time to time.

Brief Description of SF₆ Gas Liquefaction

SF₆ gas has extremely high chemical stability. It is a colorless, odorless, tasteless, and non-flammable gas at normal temperature and pressure, with excellent insulating and arc-quenching properties.

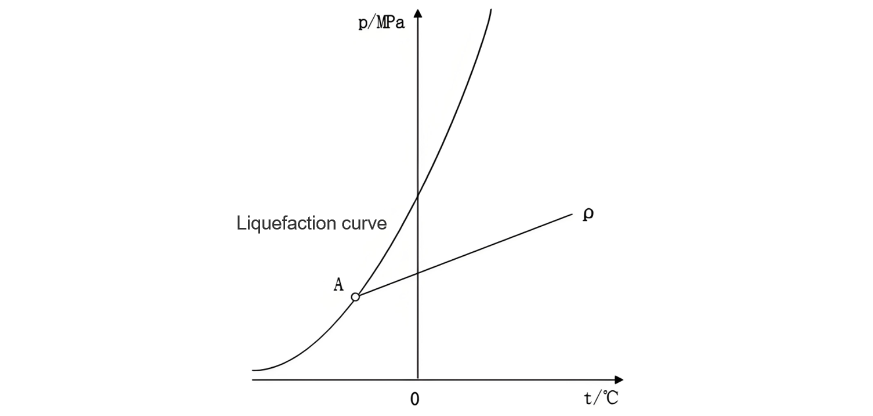

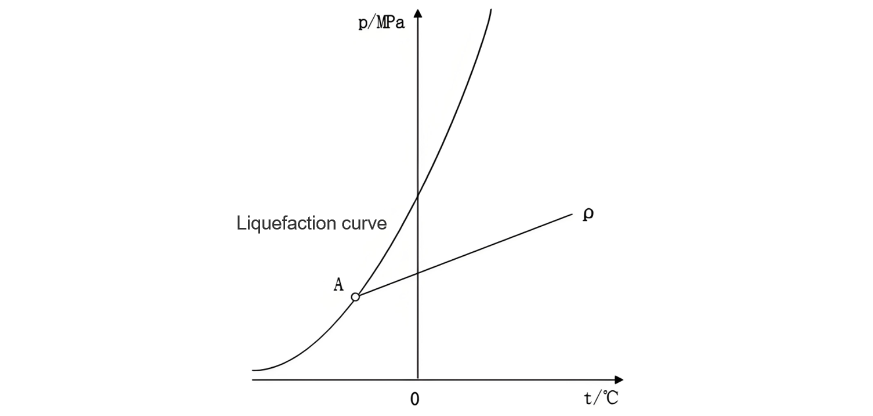

The critical temperature of a gas refers to the highest temperature at which the gas can be liquefied. When the temperature is higher than this value, the gas cannot be liquefied no matter how much pressure is applied.

For "permanent gases" such as oxygen, nitrogen, hydrogen, and helium, their critical temperatures are below -100°C, so gas liquefaction does not need to be considered at ambient temperatures. SF₆ gas is different; its critical temperature is 45.6°C. It can only maintain a constant gaseous state when the temperature is above 45.6°C. At ambient temperatures, it can be liquefied when the external pressure reaches a certain value. Therefore, for equipment filled with SF₆ gas, the problem of gas liquefaction needs to be considered.

The state parameter curve of SF₆ gas is shown in Figure 1. Under the condition of a constant gas density ρ, as the temperature decreases, the gas pressure decreases accordingly. When the temperature drops to the liquefaction point A corresponding to this gas density, the gas begins to liquefy, and the gas density then decreases.

On - site Actual Situation

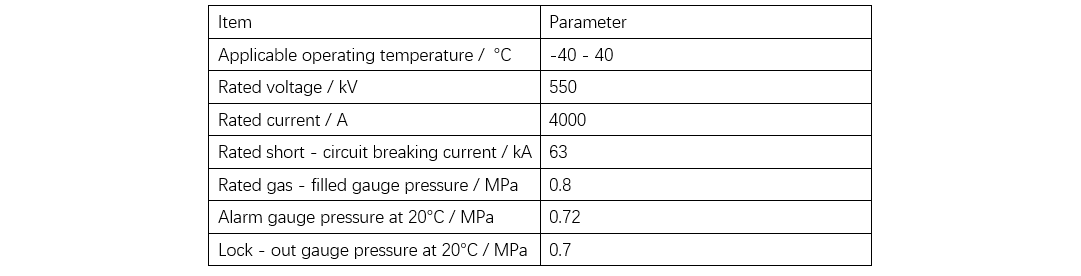

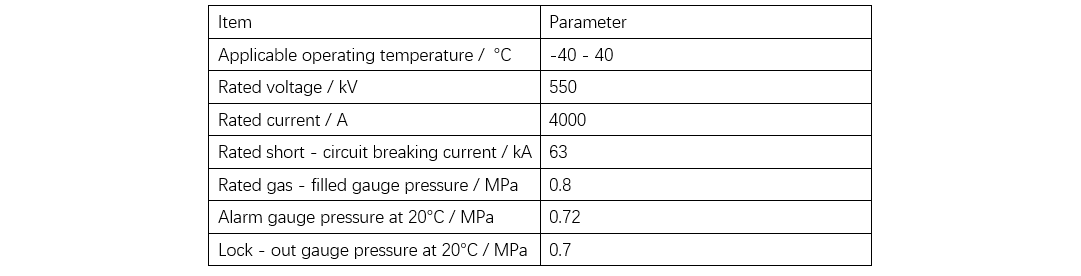

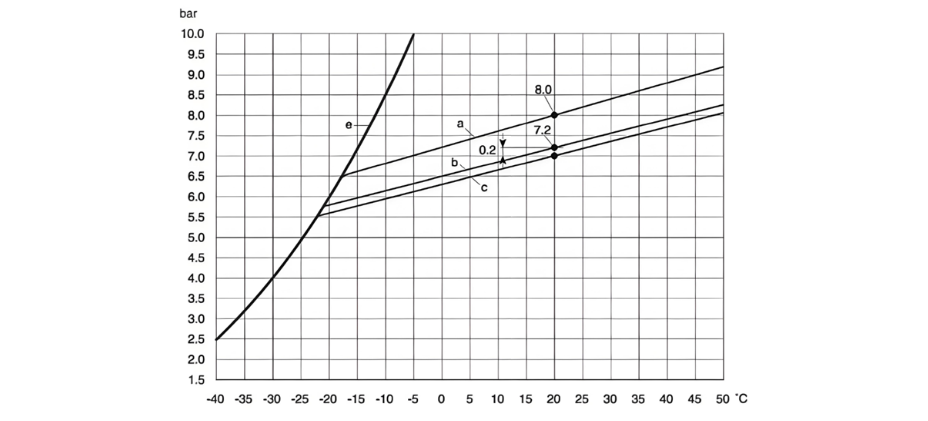

The Ximeng Converter Station is located in Chaoke Wula Sumu, Xilinhot City, Xilingol League, Inner Mongolia Autonomous Region. With an altitude of 914 meters and a latitude of 44.2°, it has a heating period of up to seven months and is classified as a severe cold region in China. In the station's AC filter yard, 20 sets of 3AP3 DT tank - type circuit breakers manufactured by Hangzhou Siemens are installed, with a rated voltage of 550 kV. These circuit breakers are equipped with density relays that have a temperature - compensation function, and their indications reflect the change in gas density rather than pressure change. The main parameters of the circuit breakers are shown in Table 1.

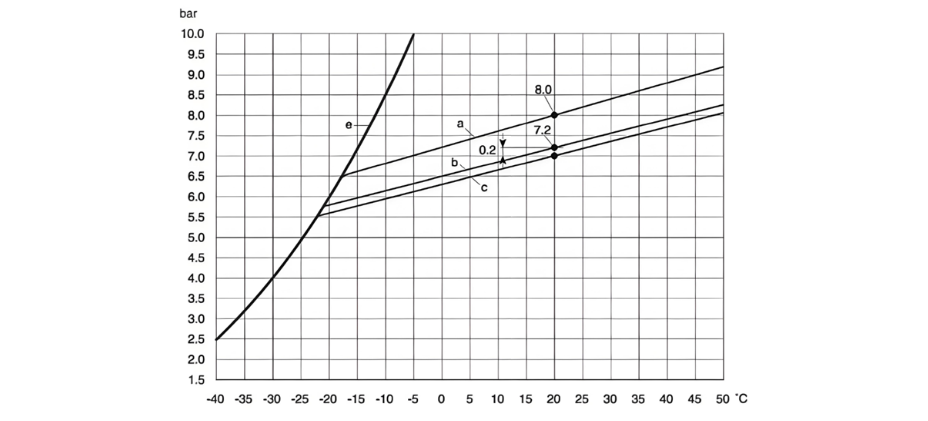

During the installation process, gas charging was carried out in strict accordance with the parameters provided by the manufacturer. The rated gas - charging pressure was set at 0.8 MPa, the alarm pressure at 0.72 MPa, and the lock - out pressure at 0.7 MPa (gauge pressure at 20°C). The state parameter curve of SF₆ gas is shown in Figure 2. As can be seen from the figure, when the tank is well - sealed and there is no gas leakage, the gas inside the tank will liquefy when the temperature drops to - 18°C; an alarm will be triggered when the temperature reaches - 21°C; and the circuit breaker will be locked out when the temperature drops to - 22°C. The actual on - site situation is shown in Figure 3.

The actual situation on site is consistent with the results obtained from the state parameter curve.

According to the on - site material supply situation and equipment installation progress, the tank - type circuit breakers completed the installation, vacuum - pumping, and gas - filling operations at the end of November. The equipment handover tests and commissioning work were concentrated in the first ten days of December. At this time, the ambient temperature had dropped below - 22°C, and all the installed circuit breakers were locked out, making it impossible to carry out the circuit breaker equipment handover tests normally and thus affecting the construction schedule nodes of the entire station.

Solutions

In view of the above - mentioned lock - out phenomena on - site, the following solutions are proposed:

Reducing Gas - filling Quantity

It can be seen from the SF₆ gas parameter characteristic curve that when the gas - filling quantity inside the tank decreases, the gas liquefaction temperature will drop, and the corresponding lock - out temperature will also decrease accordingly. For example, when the rated gas - filling pressure is adjusted to 0.56 MPa, the liquefaction temperature is - 28°C, and the lock - out temperature is - 32°C. At this time, the liquefaction temperature is lower than the ambient temperature, and there will be no lock - out phenomenon. However, after reducing the gas - filling quantity, the arc - extinguishing performance and insulating performance of the circuit breaker will both decline. Such methods involving changes to the final state of the equipment and affecting its performance need to be thoroughly studied and demonstrated by the design unit and the manufacturer before implementation.

If the final state of the equipment is not to be changed, that is, reducing the gas - filling quantity to a certain value (such as 0.6 MPa) before the handover test and replenishing the gas - filling quantity to the rated value after the test and commissioning are completed. This method may seem feasible, but in fact, it is not. First, after reducing the gas - filling quantity, the insulating performance of the circuit breaker deteriorates. Without accurate demonstration, there is a possibility that the circuit breaker break may be punctured during the withstand voltage test. Second, even if the test is passed smoothly, the test results are of no reference value. The equipment handover test is an inspection of the production quality of the manufacturer and the installation quality of the installer, and it should be carried out after the equipment installation is completely finished. And the gas - filling process is clearly a step in the equipment installation process.

Using Mixed Gas

Currently, at home and abroad, there are practices of reducing the liquefaction temperature by mixing a certain proportion of other gases (such as CF₄, CO₂, and N₂) into SF₆ gas. However, the insulating and arc - extinguishing performances of the mixed gas cannot reach the level of pure SF₆ gas. Under the same gas - filling pressure, the current - breaking capacity of a circuit breaker filled with mixed gas will be about 20% lower than that of a circuit breaker filled with pure SF₆ gas. If the same insulating performance is to be achieved, the gas - filling pressure of the mixed gas must be higher than that of pure SF₆ gas.

Taking the SF₆/N₂ mixed gas as an example, the following calculation formula can be used:

Pm=PSF6(100/x%)0.02

In the formula, Pm is the gas - filling pressure of the mixed gas to achieve the same insulating performance, PSF6 is the gas - filling pressure of pure SF₆ gas, and x% is the percentage content of SF₆ gas in the mixed gas.It can be seen from the above formula that for the SF₆/N₂ mixed gas containing 20% SF₆ gas, the required gas - filling pressure is about 1.4 times that of pure SF₆ gas. For the on - site circuit breaker, the gas - filling pressure needs to reach 1.12 MPa, which poses new requirements for the entire structure of the circuit breaker.

Installing Heating Devices

The main external factor for SF₆ gas liquefaction is that the ambient temperature is lower than its liquefaction temperature. If a tracing heater is installed around the tank to heat the tank and increase its temperature, the liquefaction problem can be solved.

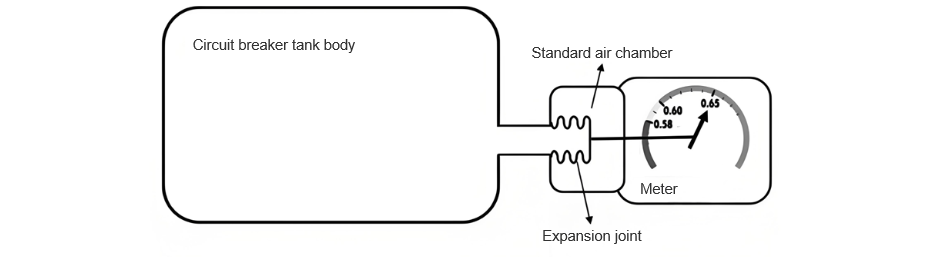

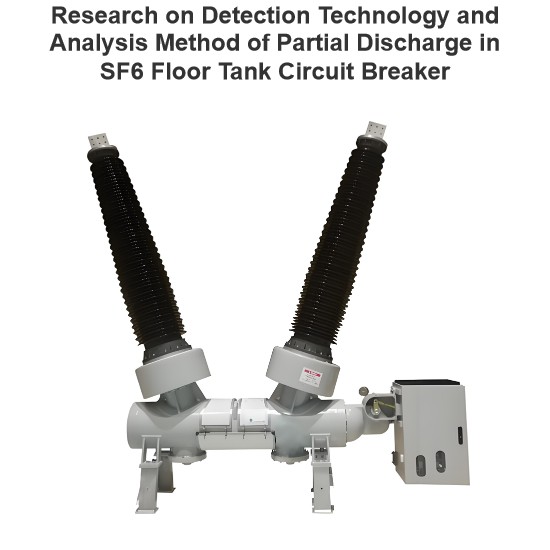

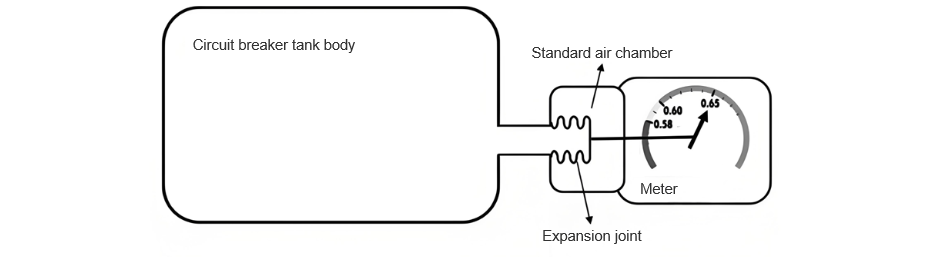

The tank - type circuit breakers of Hangzhou Siemens use the Swiss trafag density relay, which has a temperature - compensation function and its indication reflects the change in gas density rather than pressure change. The indication principle of this density relay is to monitor the gas density by comparing the pressure difference between the gas in the circuit breaker tank and the standard gas carried by the density relay. As shown in Figure 7, when the ambient temperature changes within the range above the liquefaction temperature, the gas pressures in the two gas chambers change simultaneously, the pressure difference is zero, the expansion joint does not act, and the meter pointer does not move; when the gas in the tank liquefies or leaks, the pressure of the standard gas relatively increases, the expansion joint acts, causing the meter pointer to move.

When the ambient temperature drops to the liquefaction temperature, the tracing heater activates, and the temperature of the tank rises accordingly. This creates a temperature difference between the gas inside the tank and the gas inside the expansion joint, resulting in a deviation in the meter's indication and preventing it from accurately reflecting the actual condition of the gas within the tank.

Conclusion

This paper briefly describes the liquefaction process of SF₆ gas. Regarding the SF₆ gas liquefaction problem that occurred during the installation of the tank - type circuit breakers in the AC filter yard of the Ximeng Converter Station, three solutions were proposed and discussed: reducing the gas - filling quantity, replacing with mixed gas, and adding heating devices. Through analysis and comparison, it was found that both reducing the gas - filling quantity and replacing with mixed gas would affect the insulating and arc - extinguishing performances of the gas, so they are not suitable. The method of using a tracing heater to heat the tank to prevent gas liquefaction, although it will cause a certain error in the meter's indication, can ensure the smooth progress of the equipment handover test, so it is a more appropriate solution.