Dead Tank SF6 Circuit Breaker Solution for African Plateau Regions (Ethiopia)

05/22/2025

Project Background

Ethiopia, located in the East African plateau, has an average altitude exceeding 3,000 meters. In some areas, winter temperatures can drop to -30°C, accompanied by significant diurnal temperature variations (up to 25°C daily) and intense ultraviolet radiation. The local power system faces the following challenges:

- SF6 Gas Liquefaction Risk: Traditional Dead Tank SF6 Circuit Breakers are prone to SF6 gas liquefaction at low temperatures (critical liquefaction temperature ≈ -28.5°C), compromising insulation and arc-quenching performance, potentially causing operational failures.

- High-Altitude Insulation Degradation: Reduced air density weakens external insulation strength, necessitating enhanced insulation levels or specialized designs for Dead Tank SF6 Circuit Breakers.

- High Maintenance Difficulty: Remote areas lack sufficient maintenance resources, requiring Dead Tank SF6 Circuit Breakers to feature long-term maintenance-free capabilities.

Solution

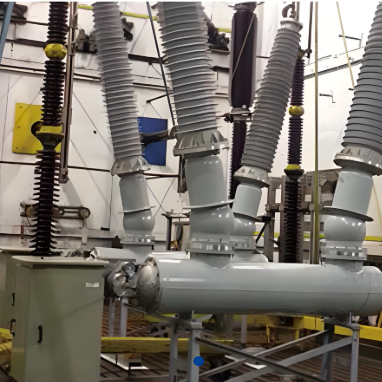

To address environmental and technical challenges, the following integrated measures were implemented for the Dead Tank SF6 Circuit Breaker:

- Hybrid Gas Optimization

• SF6+CF4 Gas Mixture: A 25% SF6 and 75% CF4 blend reduces the liquefaction critical temperature to -60°C, ensuring gas stability for Dead Tank SF6 Circuit Breakers in extreme cold.

• Pressure Control: The Dead Tank SF6 Circuit Breaker’s rated pressure is set to 0.6 MPa (gauge pressure), combined with enhanced sealing to prevent gas leakage at low temperatures. - Heating and Thermal Insulation System

• Built-in Heating Strips: A 300W electric heating system is integrated into the Dead Tank SF6 Circuit Breaker body and pressure pipelines, automatically activating below -20°C to maintain gas pressure above the liquefaction threshold.

• Dual-Layer Insulation: The Dead Tank SF6 Circuit Breaker uses an outer UV-resistant composite shell and an inner aerogel layer to minimize heat loss and withstand plateau-level solar radiation. - High-Altitude Adaptation

• Enhanced Insulation: The Dead Tank SF6 Circuit Breaker’s lightning impulse withstand voltage is upgraded to 550 kV (vs. 450 kV standard), with extended creepage distance porcelain bushings (31mm/kV).

• Seismic Design: Flexible linkages and shock-absorbing bases are added to the Dead Tank SF6 Circuit Breaker, meeting seismic requirements of 0.3g horizontal and 0.15g vertical acceleration. - Smart Maintenance Support

• Online Gas Monitoring: The Dead Tank SF6 Circuit Breaker integrates density relays and micro-water sensors for real-time SF6 mixture pressure and humidity tracking, transmitting data via satellite to central control systems.

• Modular Maintenance: A spring-operated mechanism (e.g., CTB-1 type) extends the Dead Tank SF6 Circuit Breaker’s mechanical lifespan to 10,000 operations, reducing on-site maintenance needs.

Outcomes

Since its deployment in 2024, the Dead Tank SF6 Circuit Breaker solution has delivered exceptional performance in Ethiopia’s plateau grid:

- Enhanced Reliability: Hybrid gas and heating systems enable stable operation of Dead Tank SF6 Circuit Breakers at -40°C, reducing failure rates by 85% with zero outages caused by gas liquefaction.

- Lower Maintenance Costs: Annual maintenance frequency dropped from 6 to 1, cutting costs by 30%.

- Environmental Compliance: SF6 usage in Dead Tank SF6 Circuit Breakers decreased by 75%, reducing greenhouse gas emissions by 80% compared to conventional solutions, aligning with the Paris Agreement.