| Brand | RW Energy |

| Model NO. | General Protection Device |

| Rated voltage | 230V ±20% |

| Rated frequency | 50/60Hz |

| Electric energy consumption | ≤5W |

| Series | RWH-15 |

Description

General Protection Device is a microprocessor as the core, combined with modern electronic technology, computer technology, communication technology, to realize the power system fault detection, protection control and operation monitoring function of intelligent equipment. As the key line of defense for the safe and stable operation of the power system, it replaces the traditional electromagnetic protection device and significantly improves the reliability, sensitivity and speed of protection.

The device is mainly composed of data acquisition system, microprocessor unit, input/output interface, communication module and power module. When working, the data acquisition system collects analog signals such as current and voltage in real time, and transmits them to the microprocessor after analog-to-digital conversion; the microprocessor analyzes and calculates the data according to preset protection algorithms and logic programs, and determines whether a fault or abnormality occurs in the power system; once a fault is detected, it quickly drives the circuit breaker to trip and removes the faulty equipment through the output interface and uploads the fault information to the monitoring center through the communication module. Upload the fault information to the monitoring center through the communication module

Support communication protocols: IEC 60870-5-101 IEC 60870-5-104 Modbus DNP3.0

Main function introduction

1. Protection relay functions:

1) 49 Thermal Overload,

2) 50 Three-section of Overcurrent (Ph.OC) ,

3) 50G/N/SEF Sensitive Earth Fault (SEF),

4) 27/59 Under/Over Voltage (Ph.OV/Ph.UV),

5) 51C Cold load pickup (Cold load).

2. Supervision functions:

1) 60CTS CT Supervision,

2) 60VTS VT Supervision,

3. Control functions:

1) 86 Lockout,

2) 79 Auto reclose,.

3) circuit-breaker control,

4. Monitoring Functions:

1) Primary currents for Phases and Zero sequence current,

2) Primary PT Voltage,

3) Frequency,

4) Binary Input/Output status,

5) Trip circuit healthy/failure,

6) Time and date,

7) Fault records,

8) Event records.

5. Communication functions:

a. Communication interface: RS485X1,RJ45X1

b. Communication protocol: IEC60870-5-101; IEC60870-5-104; DNP3.0; Modbus-RTU

c. PC software: RWK381HB-V2.1.3,The address of the information body can be edited and queried by PC software,

d. SCADA system: SCADA systems that support the four protocols shown in "b.”.

6. Data Storage functions:

1) Event Records,

2) Fault Records,

3) Measurands.

7. remote signaling remote measuring, remote controlling function can be customized address.

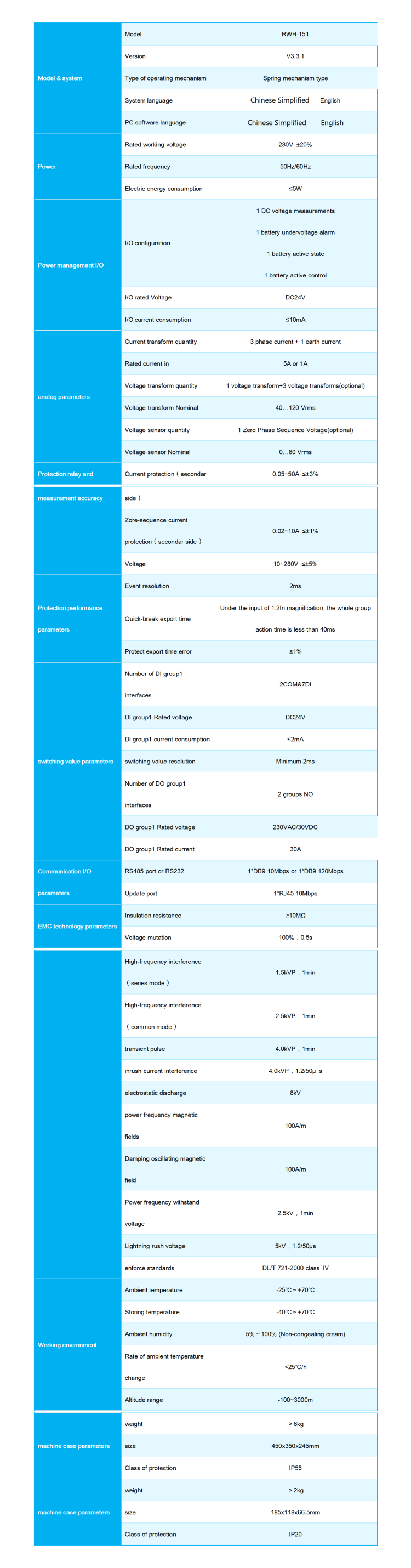

Technology parameters

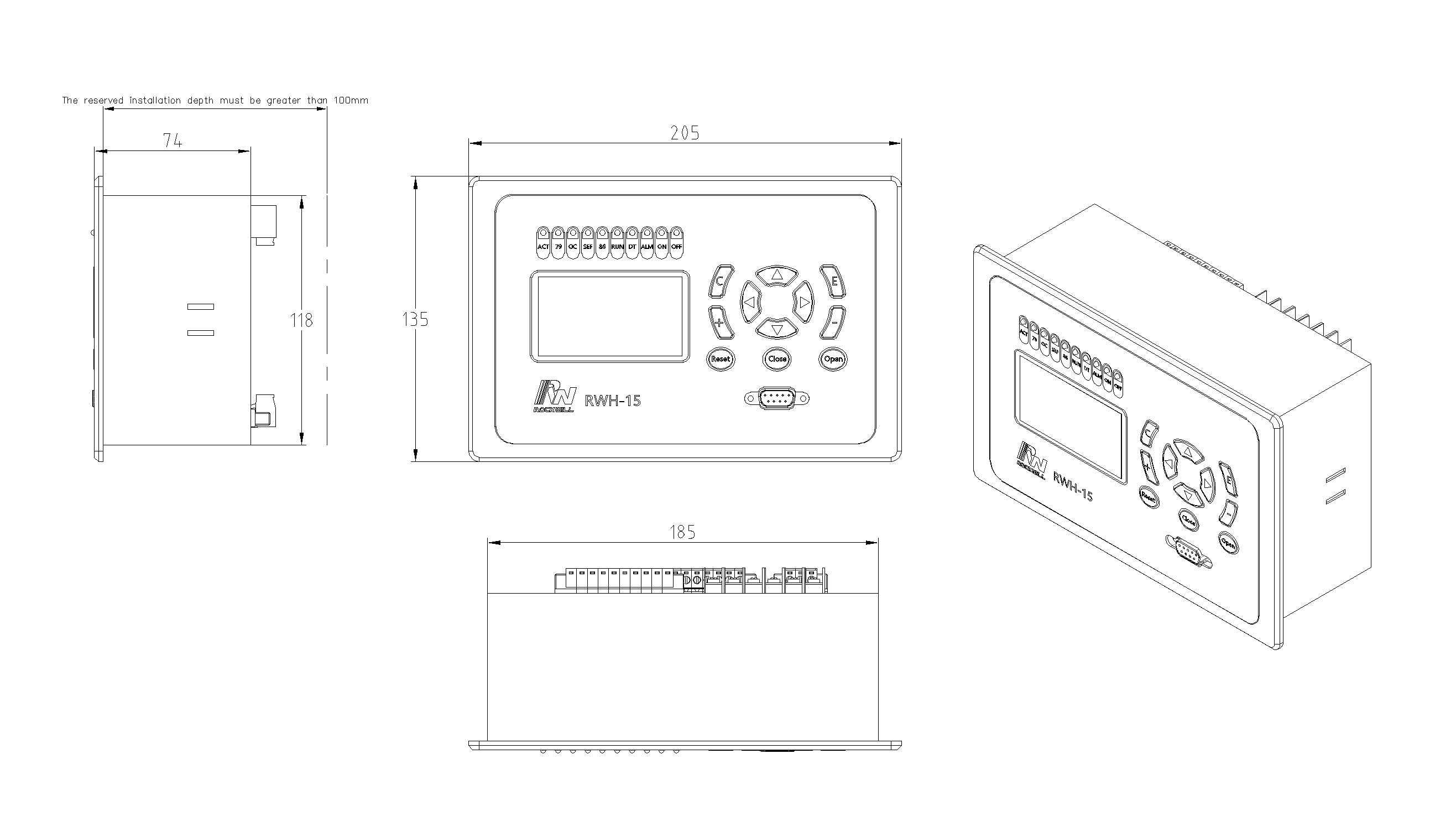

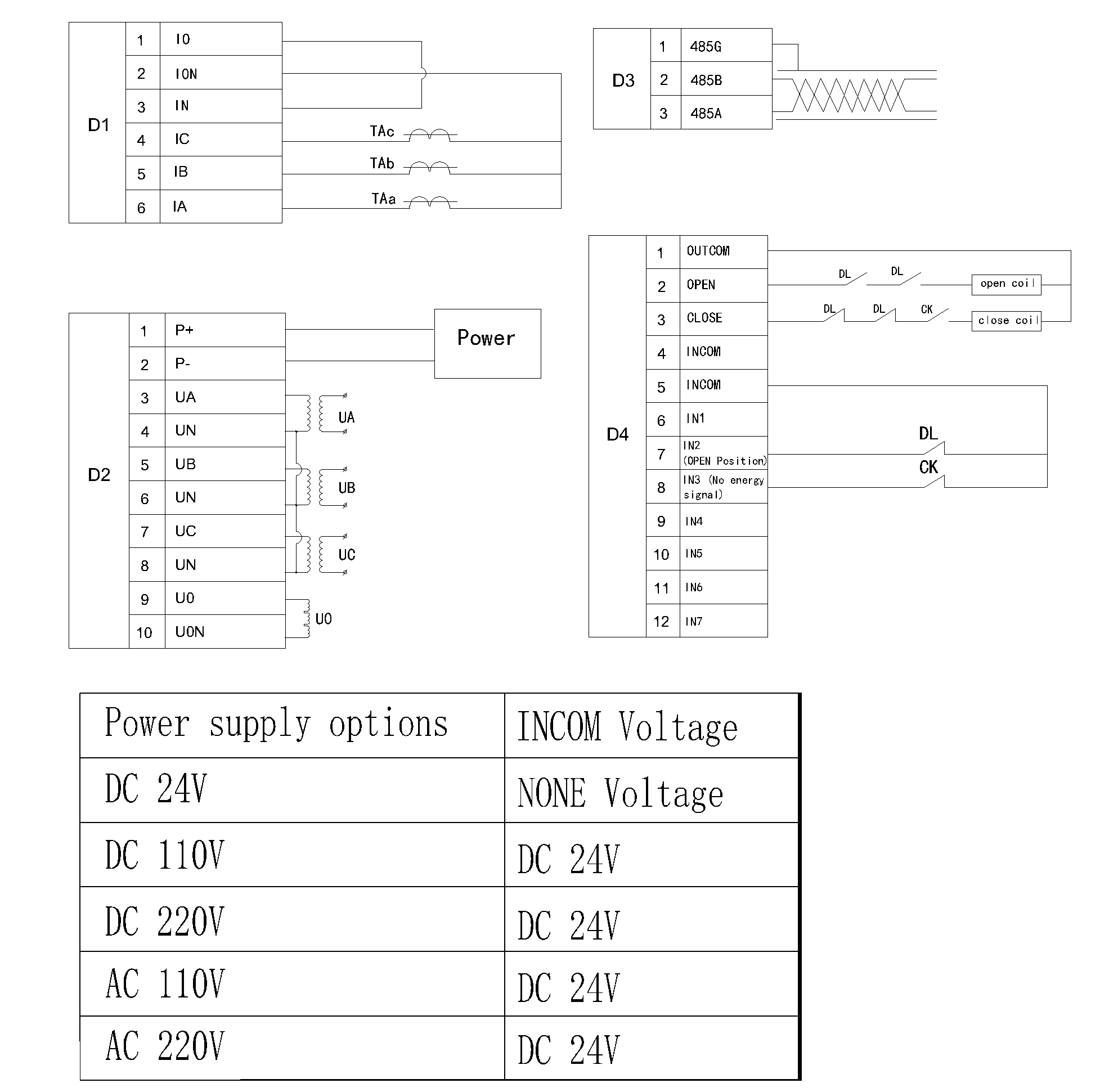

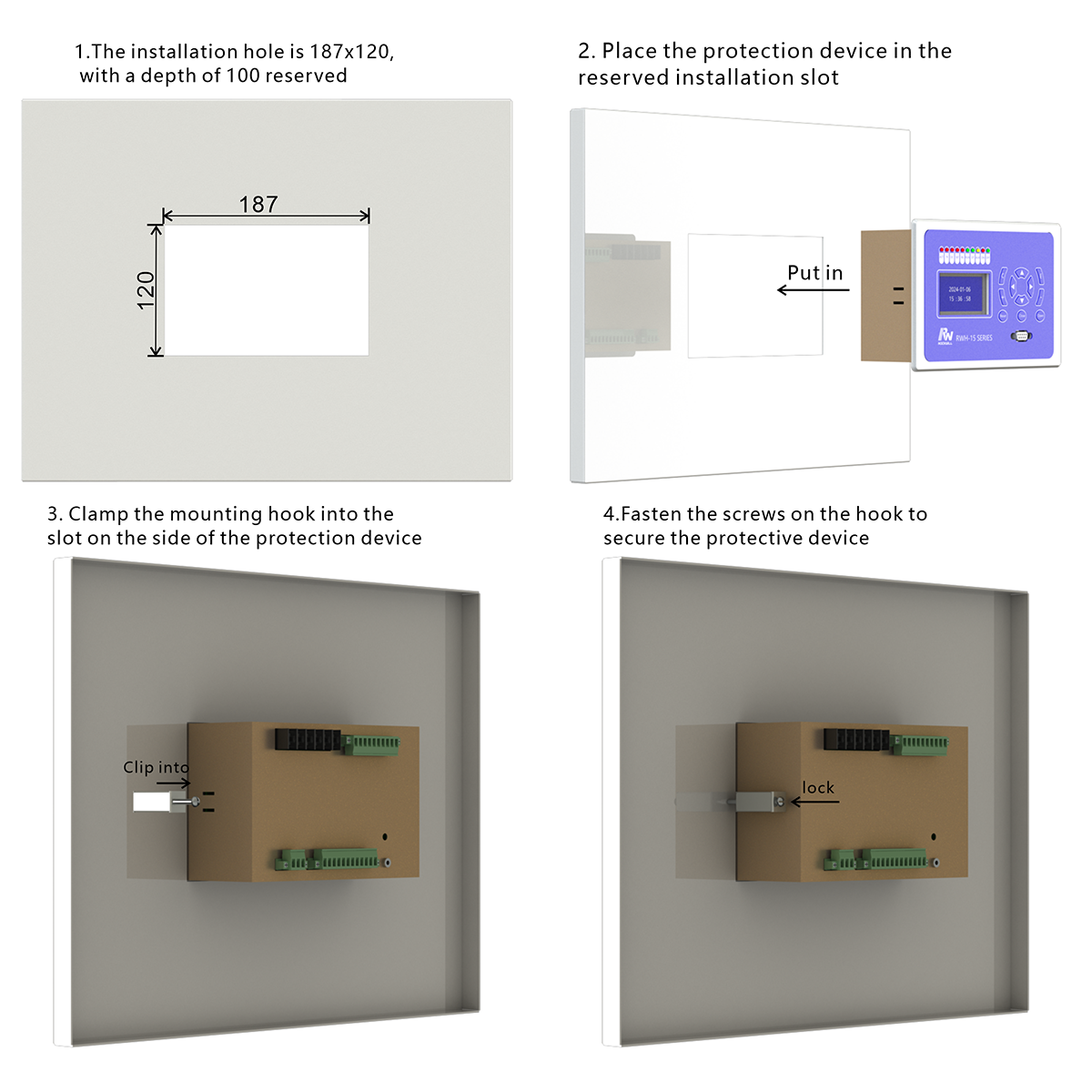

Device structure

About customization

The following optional functions are available: GPRS communication module. Upgrade SMS Function.

For detailed customization, please contact the salesman.

Q: What is the function of Microcomputer protection device?

A: The microcomputer protection device is mainly used to protect the electrical equipment in the switchgear. It can monitor electrical parameters such as current and voltage in real time. When there is overcurrent, overvoltage, undervoltage and other fault conditions, the rapid response, such as tripping to cut off the circuit, to prevent equipment damage, to ensure the safe and stable operation of the power system.

Q: What are its advantages over traditional protection devices?

A: The precision of The microcomputer protection device is higher, and the electric quantity can be measured accurately. It has the function of self-diagnosis, can find its own fault in time for maintenance. Moreover, the protection parameters can be set flexibly to adapt to different power system requirements. It can also realize remote communication and facilitate remote monitoring and operation, which is difficult to do with traditional protection devices.