| Brand | Wone |

| Model NO. | PV&ESS integrate machine |

| Cooling mode | Forced air cooling |

| Rated Output Rating | 7KW |

| Energy storage capacity | 107kWh |

| Rated PV input power | 65kW |

| Series | Industrial&Commercial energy storage |

Peculiarity:

Modular storage parallel design concept, improve system stability, easy installation and maintenance, easy expansion.

Fast realization of grid-connected/off-grid PV collaboration.

Adjustable energy scheduling, users can change the charge and discharge logic according to the power consumption strategy of different periods in the area.

Multiple protection and safety devices to ensure the safety of use.

Energy Balance Management controllers are used to refine energy management of energy storage systems down to the battery PACK level.

Battery PACK horizontal energy balance management controller to avoid capacity loss caused by mismatches.

Outdoor modular energy storage converter cabinet design, high power density, easy maintenance.

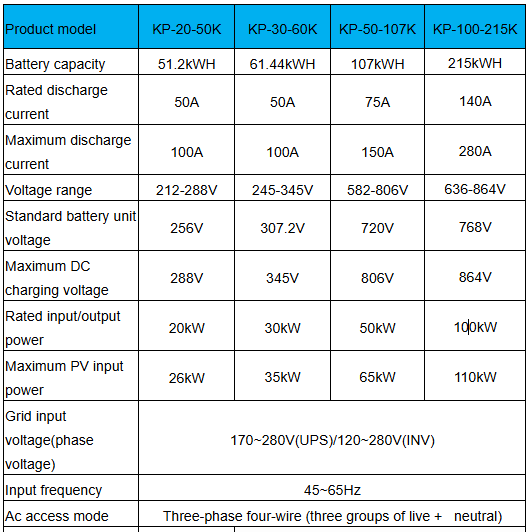

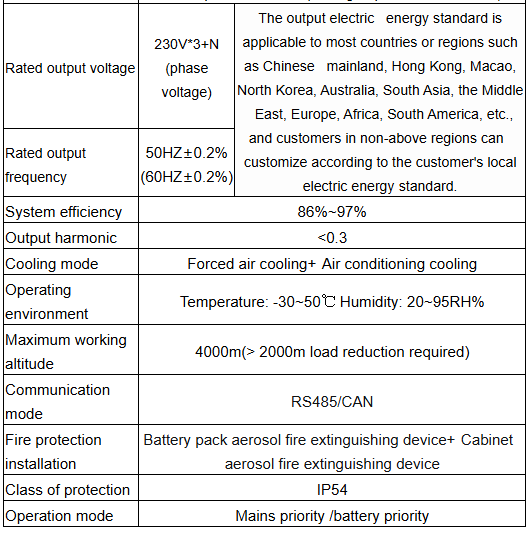

Technical parameter:

How does the photovoltaic energy storage machine work?

The photovoltaic and energy storage integrated machine is a solution that integrates a photovoltaic power generation system and an energy storage system. It is suitable for various application scenarios such as households, commerce, and industry. This type of integrated machine usually contains a photovoltaic inverter, energy storage batteries, a battery management system (BMS), an energy management system (EMS), and other necessary components.

Working principle:

Energy storage:When the photovoltaic system generates excess electrical energy, the alternating current (AC) is converted into direct current (DC) through the inverter and stored in the battery module.

Energy release:When power demand increases or supply is insufficient, the stored direct current is converted into alternating current through the inverter and transmitted to the power grid or directly used by users.

Intelligent scheduling:The EMS intelligently schedules the charging and discharging process of the energy storage system according to electricity prices, grid demands, and user settings to maximize economic benefits.