| Brand | Schneider |

| Model NO. | Power-Zone Load Center Unit Substations |

| Rated capacity | 1000kVA |

| Series | Power-Zone Model III |

Power-Zone Model III package unit substations combine a primary switch, dry-type transformer, and I-Line™ distribution section into a single, compact unit. All components are engineered, manufactured, and tested by Schneider Electric. The substation is available with a UL listing.

The Model III is only 49 inches deep and 90 inches high, which allows the entire substation to pass through standard size doorways and narrow hallways.

The Model III is front accessible; the transformer taps are accessible from the side. For proper ventilation, a minimum distance of 12 inches should be maintained on the transformer side of the equipment.

Model III package unit substations are ideal for renovations and high rise applications requiring increased customer electrical demand as well as new construction requiring multiple zones and a small footprint.

Most Model IIIs are supplied with a Square D™ brand fused HVL/cc 600 A load interrupter switch. The HVL/cc offers the smallest footprint in the industry and is an exclusive sealed interruption type compartmentalized switch. Where switching and overcurrent protection are provided elsewhere, a full-height air-filled terminal chamber can be provided in place of the switch.

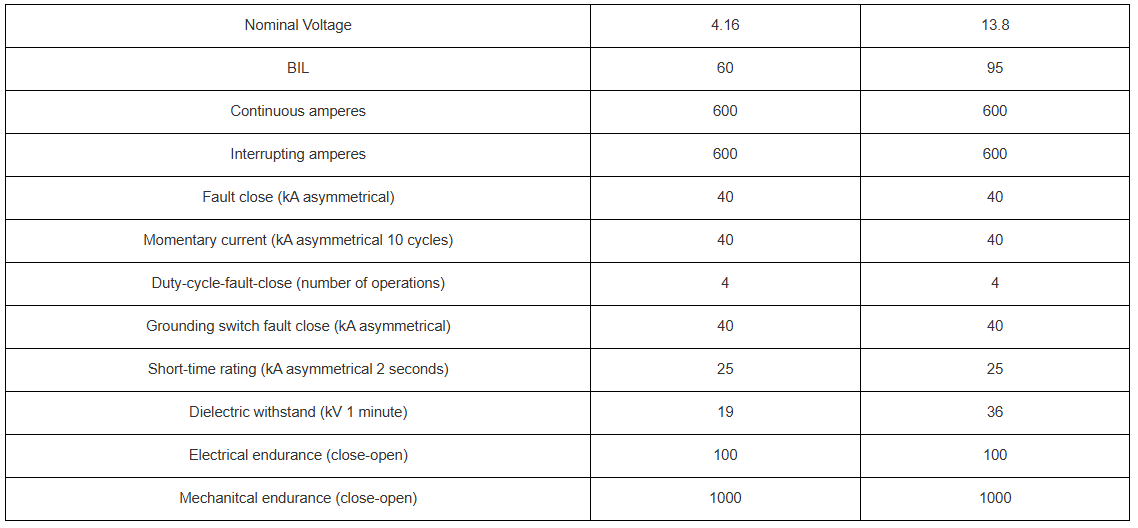

Primary Switch Ratings, Type HVL/cc

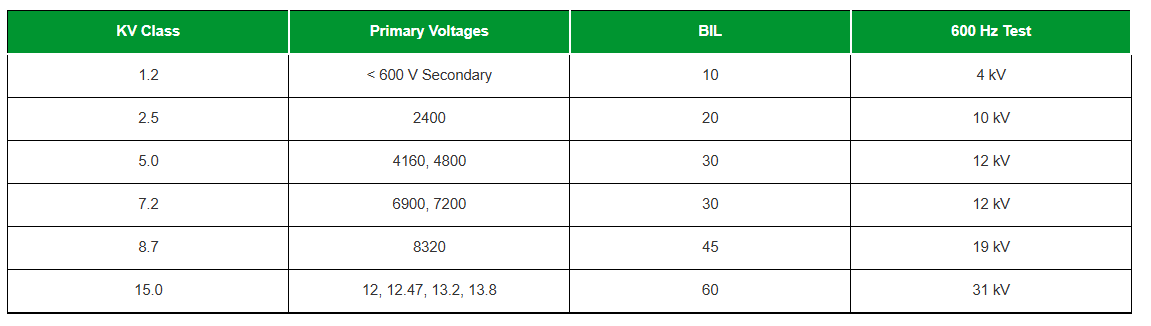

Special barrel wound dry-type transformers employing resin encapsulated VPI (Vacuum Pressure Impregnation) techniques are used to achieve the low-loss, compact design necessary for the space-saving package substation concept. Class H, 220 °C insulation is used throughout. Temperature rise is 150 °C as standard, although 80°C or 115 °C low temperature premium transformers are available through 750 kVA. Aluminum windings are standard with copper as an option. Four full capacity 2-1/2 percent taps are provided-two above nominal voltage and two below.

Fan cooling is optional. When selected, it increases the capacity rating of the transformer an additional 33 percent. The Model 98 digital controller is employed. This system provides precision control through the use of three high accuracy thermocouple type sensors—one in each phase of the windings.

The controller has a membrane front panel for displaying the temperature of all three phases with individual readings. The hottest phase is automatically displayed. The Model 98 digital controller features simple three-button operation with fan, alarm and trip function settings and is Powerlogic™ compatible.

Distribution Section

I-Line™ Mounted Molded Case Circuit Breakers

Molded case circuit breakers are group mounted in an I-Line panelboard section offering the inherent ease of installation for which the plug-on I-Line circuit breaker has become known. All circuit breakers are quick-make, quick-break, thermal magnetic, permanent trip type and are factory-calibrated and sealed for accurate overcurrent response and maximum short-circuit strength. PowerPact™ P and R circuit breakers are available with solid-state MicroLogic™ trip units. Current limiting high interrupting capacity FI, KI, and LI circuit breakers are also available. Circuit breakers may be safely back-fed for use as main circuit breakers. All circuit breakers are UL listed and carry integrated equipment rating when used exclusively with other Square D™ brand circuit breakers in intended assemblies.

I-Line panel is available in 1200 A. Maximum mounting space is 108 inches.

Tin-plated copper bus is standard.

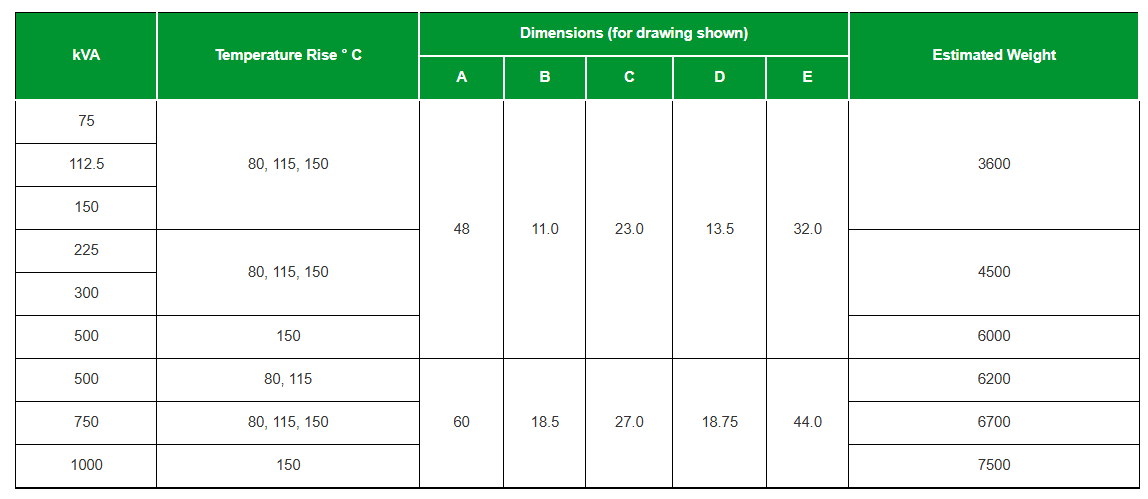

Substation Dimensions and Approximate Weights