| Brand | Vziman |

| Model NO. | Ladle refining furnace transformer |

| Rated capacity | 20000kVA |

| Series | Ladle refining furnace transformer |

Description:

In recent years, with the increase of transformer manufacturers in developed countries and electric furnace steel smelting furnace, make our transformers matched with LF furnace changed, which is less than LF of 40t furnace still choose the traditional type, more than 40t of LF furnace transformer structure, mainly by Demag and Dunelli as typical,Demag requires the selection of transformer transformer as a way into the top two as triangle, triangle side water-cooling tube type high pressure water cooler outlet, cooler is hanging in the transformer on the host, and Dan Neely required transformer as a way into the top two copper bars before and after staggered, internal sealing triangle the outlet box cover,Other requirements are basically similar, but the integrity of the transformer. Free maintenance is the same, and the transformer loss requirements are very strict, so my company production of LF furnace transformer has the performance of developed countries and international products have been consistent, even better than the level of imports, because the number of products and specifications there is now a series of reference and user usage, by the relevant departments of our company drafting organization formed by discussion, the national standard of LF furnace transformer, the details of the product introduction as follows:

In line with the requirements of energy saving and consumption reduction in iron and steel industry, transformers, which are the main equipments used in iron and steel smelting, are aiming at reducing the power consumption per ton of steel and other factors. Our company pursues the following four goals in transformer equipment and manufacturing.

Transformer itself has good energy saving characteristics, that is, no-load loss, no-load current and load loss. As far as possible, reduce the percentage of impedance voltage and choose the right capacity on the commonly used capacity. By using the existing high-quality raw materials and using advanced technology such as small oil gap, the transformer will truly become an energy-saving type, and the performance level is consistent with that of the developed countries.

Transformer has very stable reliability and long service life. The design technology of new structure should be verified by operation test and type test, and the design life is no less than thirty years.

Requires a certain load capacity to ensure that the user in the excess nominal capacity, 20% load conditions, the operation of the appropriate operation.

Reduce the maintenance workload of users, users no longer in the long-term use of the core, the design of maintenance free time is not less than ten years. The free repair time is twenty years.

Selection of material, structure and technology of transformer: the following six parts are introduced as a brief introduction

That is: iron core, winding, body, oil tank, assembly, accessories. The following are introduced:

core: from the material we have chosen Baowu Steel Group 30Z130 silicon steel or the Japanese Nippon Steel Corporation 30Q130, the basic material and international developed countries use the material is the same.In the structure, the fully oblique joint type is adopted, the upper and lower clamping parts are connected with the pull plate structure of the low magnetic steel plate, which changes the former square iron structure, makes the iron chip without holes, and the magnetic flux density of each section of the iron core is consistent.Without distortion, imported from Germany Georg shear line in the shearing process, control cutting burr (standard <0.05 <0.02mm for qualified products) per meter length tolerance <0.2mm thereby increasing the lamination coefficient reduces the gap clearance, to avoid the core local overheating, reduces noise and no-load loss and no-load current.

The use of oxygen free copper wire winding from the material, control the P <0.017241 20 degrees, in addition to control the paper packaging materials and degree of insulation, the purpose is to make the coil has better axial and radial stability, coil with small oil gap, inside and outside the oil covering plate, guide, cooling cylinder structure, the compact overload capacity and thermal stability improved. The loss also declined.

All wooden parts of the body are changed into laminated wood, which improves the rigidity of the lead frame. The upper and lower pressboards are pressboard or epoxy molded parts. Compared with the iron plate, the insulation distance between the electric conductor and the ground is increased, and the size of the window height can be reduced.The one or two main insulation used imported cardboard, increased the strength of the main insulation, the multi coil adopted a whole suit, and improved the reliability of the product. The drying equipment of the body is used in Norway steam - producing drying equipment, which is completely dry and does not damage the insulation, and has the function of the flushing body.

The tank tank is made of folded plate, minimize weld, increase the strength for positive and negative pressure test, to ensure the reliability of sealing products, the use of low magnetic steel or magnetic shielding in the proper position to reduce the additional loss of wire bus field generated on the tank wall. This work has achieved very good results in seepage prevention and loss reduction.

General Assembly: after the body is dried, the winding loosening is achieved by the hydraulic equipment compaction. The vacuum oil injection is applied to reduce the bubbles in the product windings, reduce the partial discharge and increase the life of the products. A new type of sealing material with anti aging has been used to improve the original leakage problem.

Appendix: the main accessories water cooler is tube type or spiral plate type oil and water cooler, or dispersed installation, or directly fixed to the main engine of transformer. In addition to the use of imported ABB, MR or Changzheng one, there is a remote control interface, except for remote display. The transformer oil is a naphthenic antiaging transformer oil produced in Karamay, and the oil is protected by a full closed structure (the pressure release valve and diaphragm storage cabinet structure).

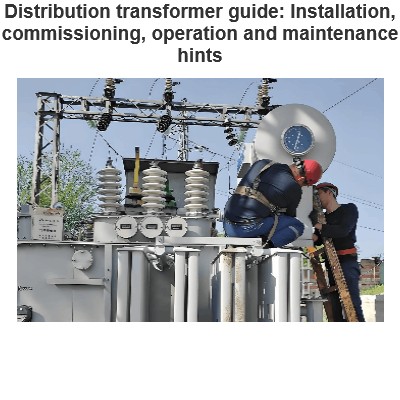

on the maintenance of transformer:

For hanging core products after arrival as long-distance transport is necessary, mainly to resolve the fastener transport loose and users of manufacturers product acceptance, but a routine overhaul, we think of those mechanical wear parts according to the original overhaul cycle check replacement is necessary.

Quality assurance measures:

Quarantee the long-term overload of 20%. For example, the capacity of LF furnace transformer is 20000kVA, the design reference capacity of the winding shall be set to 24000kVA, especially the current density and switch selection. According to 24000kVA, the impedance voltage is no more than 8% at 24000kVA. With good external characteristics and economy, the heat load calculation of transformer is set to 24000kVA. According to the margin of 24000kVA, we choose the matching parts such as lead, two outlet, cooler and so on.

Technical measures against impact and short-circuit resistance:

Our company due to the production of electric furnace transformer for a long time, especially the impact state of electric arc furnace, the furnace is worse than LF, the main technical measures used by our company is to improve the axial stability of the transformer coil, radial, so as to reduce the impact on each transformer coil damage accumulation.

Specific measures:

select a high voltage grade and wrap the paper tightly on the surface of the electromagnetic line.

The electromagnetic wire is dried first, then the coil insulation paper is wet, which affects the amplitude of the coil.

And padding blocks are used after confidentiality to reduce the pressure margin of the axial coil.

Stay to hair treatment, to reduce the stay and block "friction dovetail" between the axial pressing force of the coil in the transfer resistance is small.

And coils are dried by constant pressure.

Inside the ring adopts multi support, outside circle with struts, ensure short-circuit line displacement of small cake.

And steam phase drying are used. H, the body is pressed to use the hydraulic device.

Guarantee the free overhaul of technical measures within 20 years:

Our products mainly consider the first transformer winding with stable and reliable, which have been described, followed by the protection of transformer oil aging and seal aging, transformer oil, we choose Xinjiang Karamay naphthenic oil, anti-aging ability, structure and closed,Diaphragm storage cabinet with pressure relief valve, the oil is not in contact with air, so 20 years of oil under normal operating conditions available in the anti leakage on the main sealing surface in addition to the use of anti aging pad, to do machine processing, the metal pad and the three surface pressure, contact with air is also reduced normal users every 6 months of chromatographic analysis, and stored in a file, to distinguish the normal aging oil,And fault operation, to ensure safe use of the product, recommended load switch transformer, according to the number of operations often do a switch breakdown voltage of oil, should make its value in the design is in line with the switch to consider the body all the fasteners used butterfly locking washers, strengthening anti loose reliability.

The characteristics of appearance: the product is compact in design, and all kinds of transformer control lines are connected to the unified junction box, indicating the use, making the appearance beautiful and easy to operate.Such as iron core flux density, winding current density, transformer weight and so on, if it is not to be rejected, it will bring adverse effects to the overall efficiency of the product, because the progress of material and structure, some constraints are often contrary to expectations.Such as iron core flux density, winding current density, transformer weight and so on, if it is not to be rejected, it will bring adverse effects to the overall efficiency of the product, because the progress of material and structure, some constraints are often contrary to expectations.In recent years, the requirements of users have been greatly changed, and the development of new energy saving calcium carbide furnace transformers has been promoted. Now, as our transformer manufacturers, there are four points for pursuing:

First, the low load and load loss of products;

The two is product reliability and longevity.

Three is to have a certain load capacity (overloading 20% long term use); Four is a complete set of maintenance as little as possible. According to the requirements of users, our company has eliminated all the products produced three years ago. Most of the new orders have been changed on the user's orders, which has changed the appearance of the products and made the users get good economic benefits.

The improvement of the material, structure and process of the transformer:

A complete transformer of the ore heating furnace is divided into six parts: iron core, winding, body, tank, assembly and accessories.

From the core material we have chosen BaoWu steel group 30Z130 silicon steel or the Japanese Nippon Steel Corporation 30Q130, the basic materials and international developed countries use the material is the same.The structure adopts full inclined joint sheet type, pull plate structure under the clamp connection with low magnetic steel sheet, change the iron structure before, make the iron chip without holes intact, each section of iron core magnetic flux density, without distortion, imported from Germany Georg shear line in the shearing process. <0.02mm (standard <0.05 control of cutting burrs for qualified products) per meter length tolerance <0.2mm thereby increasing the lamination coefficient reduces the gap clearance, to avoid the core local overheating, reduces noise and no-load loss and no-load current.

Winding material from the copper electromagnetic wire little progress, I mainly control the P <0.017241 20 degrees, in addition to the main control of the paper packaging materials and degree of insulation, the purpose is to make the coil has better axial and radial stability, coil with small oil gap, inside and outside the oil covering plate. The guide, cooling cylinder structure, compact structure, stable thermal overload ability strong, the loss also declined.

For the large load voltage regulation and 110kV grade products, the "8" type coils are all wound in one time, increasing the strength of the coil and reducing the eddy current loss.

All wood parts of the body are laminated wood, which improves the rigidity of the lead frame. The upper and lower pressboards are made of pressboard or epoxy molding parts. Compared with the iron plate, the insulation distance between the conductor and the ground is increased, and the "window height" dimension is reduced. The one or two main insulation used imported cardboard, increased the strength of the main insulation, the multi coil adopted a whole suit, and improved the reliability of the product. The drying equipment of the body is used in Norway steam - producing drying equipment, which is completely dry and does not damage the insulation, and has the function of the flushing body.

Fuel tank using folded plate, minimize weld, increase the strength for positive and negative pressure test, to ensure the reliability of sealing products, the use of additional loss of low magnetic steel or magnetic shielding in the proper position to reduce the bus conductor in magnetic field generated on the wall of the box. This work has achieved very good results in seepage prevention and loss reduction.

General Assembly: after the drying of the body, the winding is relaxed and the hydraulic equipment is pressed to achieve good results. The vacuum oil injection is applied to reduce the bubbles in the product windings, reduce the partial discharge and increase the life of the products. A new type of sealing material with anti aging has been used to improve the original leakage problem. All control lines, such as gas relay, signal thermometer, resistance thermometer, pressure relief valve, magnetic oil meter and CT, are all integrated into the box on the box, and the overall appearance of the transformer is improved.

Annex a selection of main water cooler YS1 type water cooler, or stainless steel spiral plate cooler, high voltage bushing with pollution type increases the creepage distance. The OLTC uses advanced manufacturers "type M" or "V" in addition to the requirements of the remote display, and remote control interface when necessary, can be added to the oil in the switch device online. Transformer oil is made from naphtha based anti aging transformer oil in Karamay, Xinjiang. The protection of oil is totally closed structure, that is, pressure release valve and diaphragm storage tank structure.

Discussion on the development trend of the transformer in the ore heat furnace:

Due to the improvement of production process of smelting furnace, also had a great impact on the structure of the transformer, such as the development of closed smelting, led to transformer above 15000kVA, designed for single-phase transformer, water-cooling tube (adjustable tube) side outlet, OLTC, uniform structure cooling, such products have been produced set.

Some views on transformer maintenance:

For hanging core products after arrival as long-distance transport is necessary, mainly to resolve the fastener transport loose and users of manufacturers product acceptance, but a routine overhaul, we think of those mechanical wear parts according to the original overhaul cycle check replacement is necessary. For example, the running parts such as pumps, but for a relatively static transformer, there is no need to suspend the core for long time. Only monitoring the change of the gas chromatographic value of the oil is enough to grasp the situation of the body, so as to save maintenance costs and reduce the pollution of the core to the body and oil.