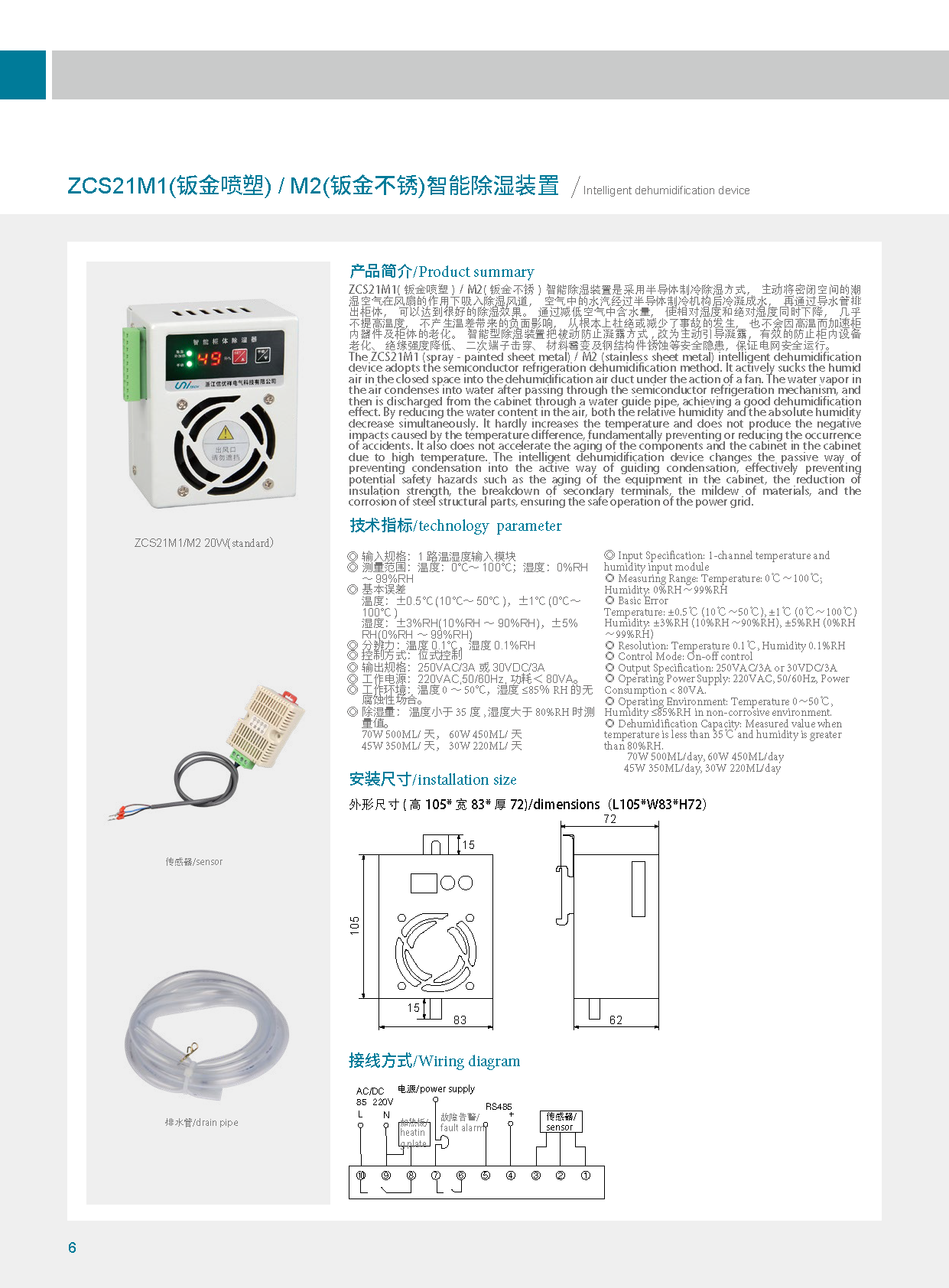

| Brand | Wone Store |

| Model NO. | Iron shell type Intelligent dehumidifier |

| Rated voltage | AC220V+10% |

| Rated frequency | 50/60Hz |

| Communication port support | RS485/RF |

| Rated power | 60W |

| cabinet type | iron plate |

| Series | ZCS21M1/M2 |

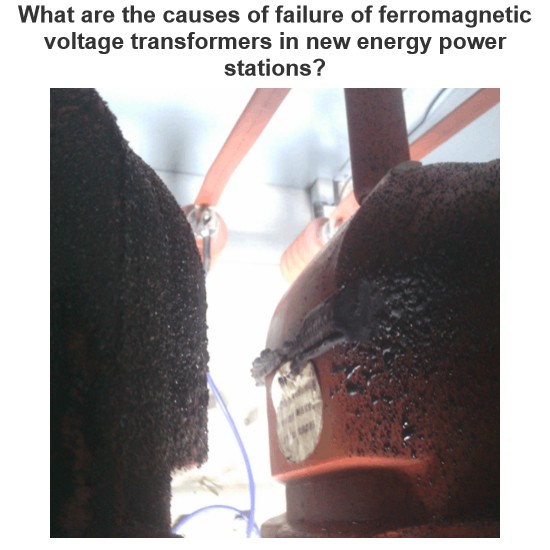

The semiconductor dehumidifier for switchgear is a reliable assistant to safeguard the stable operation of the switchgear, focusing on dealing with the problem of humidity inside the cabinet. In the power system, due to factors such as high environmental humidity and large temperature differences between day and night, the switchgear is prone to condensation inside. Excessive water vapor not only accelerates the corrosion and aging of electrical components, reduces insulation performance, but in severe cases, it may also cause short - circuit faults, threatening the safety and stability of power supply. This dehumidifier uses semiconductor refrigeration technology and operates based on the Peltier effect. The semiconductor refrigeration sheet inside, when powered on, cools rapidly on one side and heats up on the other side. When the humid air inside the switchgear is sucked into the dehumidification air duct by the fan and comes into contact with the cooling surface, the water vapor immediately condenses into liquid water upon cooling and drains out of the cabinet along the water guide pipe. The air passing through the heating surface has a slightly increased temperature and returns to the cabinet in a dry state, avoiding negative impacts caused by temperature differences. The semiconductor dehumidifier for switchgear has multiple practical features. It has low energy consumption, is energy - saving and environmentally friendly, and effectively reduces operating costs. It is small in size, light in weight, and easy to install, and can be flexibly adapted to the spatial layouts of various switchgears. At the same time, some products are equipped with high - precision humidity sensors and intelligent control systems, which can accurately monitor the humidity inside the cabinet in real - time. Once the humidity exceeds the preset safe range, the dehumidification operation is automatically started, and when the humidity reaches the standard, it stops automatically, achieving intelligent and unattended high - efficiency dehumidification, and creating a dry and stable operating environment for the switchgear in all aspects. All series come with a communication function and can be connected to the background monitoring system through the RS485 interface. Maintenance personnel can remotely and real - time monitor the operating status of the dehumidifier and the humidity data inside the cabinet, which is convenient for timely fault diagnosis and maintenance management, further improving the intelligence level and safety of power equipment operation and maintenance.