| Brand | Wone |

| Model NO. | 252KV 363 KV SF6 Circuit Breaker |

| Rated voltage | 363kV |

| Rated normal current | 4000A |

| Series | LW10B |

Description:

SF6 circuit-breaker, the circuit-breaker adopts SF6 gas as insulation and arc extinguishing medium, and its arc extinguishing chamber is a single voltage variable opening distance, which is mainly used to meet the rated current and fault current, convert the line, and realize the control and protection of the transmission line. It is equipped with a spring energy storage hydraulic operating mechanism for opening, closing and automatic reclosing. The circuit breaker is divided into two kinds of products: break without closing resistance and break with closing resistance.

Main Features:

The arc extinguishing chamber structure design of the circuit breaker is reasonable, the breaking ability is strong, the contact electric life is long (rated short circuit breaking up to 20 times), and the maintenance interval is long.

The mechanical reliability of the product is good, to ensure the mechanical life of 5,000 times.

The circuit breaker operation noise is low.

The new hydraulic operating mechanism has no exposed pipeline, reducing the oil leakage link.

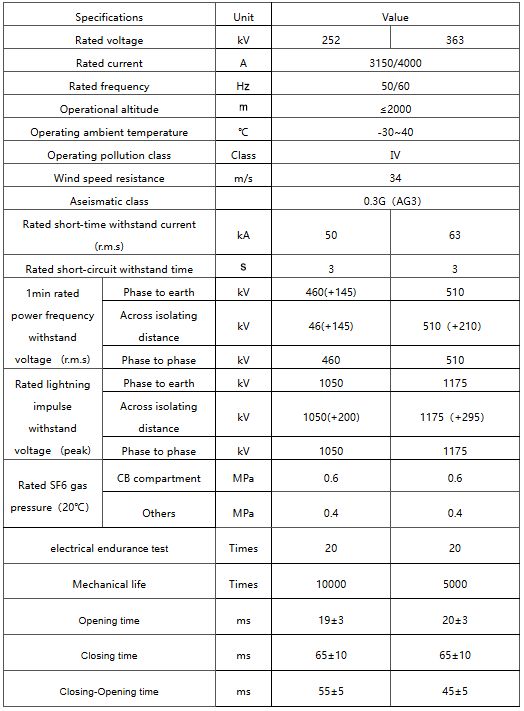

Technical parameter:

How to deal with the circuit breaker quickly when it fails?

Fault Handling:

Establish a fault handling procedure to quickly take action once a fault is detected, minimizing downtime.

Record the details of the fault and the handling process for subsequent analysis and improvement.

Emergency Response Plan:

Develop an emergency response plan that includes steps for emergency shutdown, fault diagnosis, repair, and recovery, ensuring a swift response in case of unexpected situations.

Conduct regular emergency drills to enhance the emergency response capabilities of the operating personnel.