| Brand | Wone |

| Model NO. | LW58A Series Dead Tank circuit breaker |

| Rated voltage | 72.5KV |

| Rated normal current | 2500A |

| Rated frequency | 50/60Hz |

| Rated short circuit breaking current | 40kA |

| Series | LW58A-40.5(72.5)(145)(252) |

Product introduction:

LW58A-40.5/72.5/145/252 Dead Tank circuit breaker is a new generation of open high-voltage electrical equipment developed independently ,The tank type circuit breaker is composed of the entrance bushing, lead-out bushing, CT, arc extinguishing chamber, chassis, operating mechanism, etc. It can be used in the high-cold and high-altitude area, At present, the new generation of tank type LW58A-40.5/72.5 products have reached the leading domestic and international advanced level in advanced technology and quality reliability.

Main characteristic:

Good anti-seismic performance, the product is equivalent to the seismic grade of GlS.

(a)Horizontal arrangement of arc extinguishing chamber, low center of gravity.

(b)Auto seismic frequency: The porcelain column breaker is about 4.5 Hz, and the tank circuit breaker is about 13.5 Hz.

The electric tracing band solution can be used in the high-cold region, which can not be realized by the porcelain column circuit breaker.

The product can be used in an area of 5000m , the standard configuration of the arc extinguishing chamber & drive system can only be fixed with the height of the outlet casing.

The tank type circuit breakers integrates the straight through current transformer, the product covers a small area the quality is stable, and the on-site maintenance work is small. At the same time, it solves the problems such as the small margin of CT insulation ,the limitation of CT capacity and the high cost ,aging, cracking and explosion of the CT.

Design of an arc extinguishing chamber:Horizontal Structure, it adopts thermal expansion and auxiliary pressure gas extinguishing technology, which has small operation work, excellent breaking performance and more than 20 electrical life.

Environment adaptability:It is suitable for severe environment conditions (such as severe pollution, water fog, hall, etc.), high - altitude area, high altitude area, earthquake area, the box body is sealed with air bag type, and the body protection grade is lP66.

The CT of variable ratio and multi-level combination can be attached, high accuracy, easy to add capacity, and meet 80% or the operating frequency voltage under the value of 5Pc, can be configured with TPY.

Complete CT protection measures: CT shell is sealed at both ends of the shell and has special ant-condensation design.

The light spring operating mechanism adopts the overall cast aluminum frame. Breaking spring , closing spring and buffer are arranged in a centralized manner, and all adopt spiral double pressure spring, compact structure, not easy to fatigue.

The product is small, with integrated design, integrated supply, integrated installation conditions.

With the breaking capacity of the 4000A back-to-back capacitor bank.

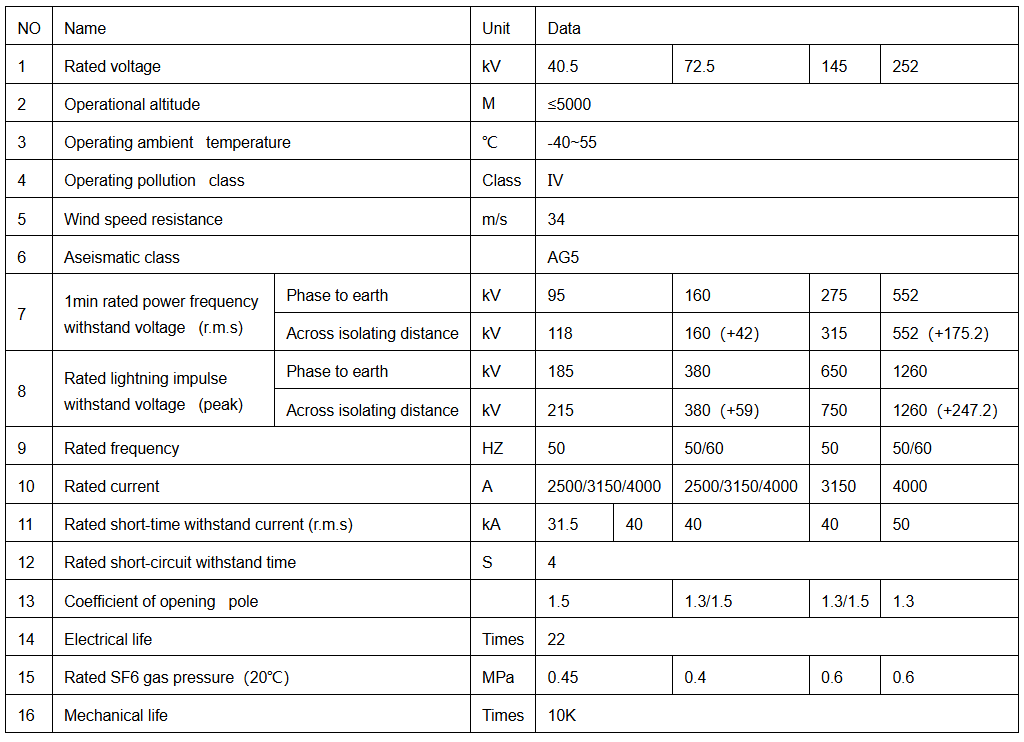

Main technical parameters:

Order Notice:

Model and format of circuit breaker.

Rated electrical parameters (voltage, current, break current, etc).

Working conditions for using (environment temperature, altitude, and environment pollution level).

Operating voltage of operating mechanism and motor voltage.

The number of current transformer, current ratio, class combination and secondary load.

Names and quantities of spare items needed, parts and special equipment and tools(to be otherwise ordered).

What are the structural characteristics of the tank circuit breaker?

Integral Tank Structure: The breaker's arc quenching chamber, insulating medium, and related components are sealed within a metal tank filled with an insulating gas (such as sulfur hexafluoride) or insulating oil. This forms a relatively independent and sealed space, effectively preventing external environmental factors from affecting the internal components. This design enhances the insulation performance and reliability of the equipment, making it suitable for various harsh outdoor environments.

Arc Quenching Chamber Layout: The arc quenching chamber is typically installed inside the tank. Its structure is designed to be compact, enabling efficient arc quenching within a limited space. Depending on different arc quenching principles and technologies, the specific construction of the arc quenching chamber may vary, but generally includes key components such as contacts, nozzles, and insulating materials. These components work together to ensure that the arc is quickly and effectively extinguished when the breaker interrupts the current.

Operating Mechanism: Common operating mechanisms include spring-operated mechanisms and hydraulic-operated mechanisms.

Spring-Operated Mechanism: This type of mechanism is simple in structure, highly reliable, and easy to maintain. It drives the opening and closing operations of the breaker through the energy storage and release of springs.

Hydraulic-Operated Mechanism: This mechanism offers advantages such as high output power and smooth operation, making it suitable for high-voltage and high-current class breakers.