| Brand | POWERTECH |

| Model NO. | 35kV Low Loss Prefabricated Compact Substation for Grid |

| Rated voltage | 35kV |

| Series | YBW-35/0.4-2000 |

Description

An AC metal-enclosed shift switch cabinet is a three-phase, 50Hz indoor metal-enclosed switching device designed for power plants and substation systems. It operates at a rated voltage of 35kV, with a maximum current capacity of 2000A and a voltage limit not exceeding 40.5kV. Suitable for single-bus or single-bus segmented configurations, it serves as a reliable distribution solution.

This switchgear complies with standards such as DL/T 404-91, IEC 298, and GB 3906, incorporating essential safety features to prevent operational errors. These include protections against incorrect circuit breaker operation, live insertion or withdrawal of trolleys, grounding line faults, live grounding, and accidental energization of isolated sections (commonly referred to as the "five protections").

Compact substations are ideal for diverse applications, including residential communities, urban public distribution networks, busy downtown areas, and temporary construction power supply. Their versatility allows selection based on specific load requirements and environmental conditions. Since their introduction, compact substations have seen rapid adoption, with widespread use in developed countries—where they account for a significant share of distribution systems. In China, modernization and urban grid upgrades are driving their increasing deployment.

These substations are commonly employed in high-rise buildings, luxury residences, parks, residential complexes, small to medium industrial plants, mining operations, oil fields, and temporary construction sites, providing efficient power distribution within electrical networks.

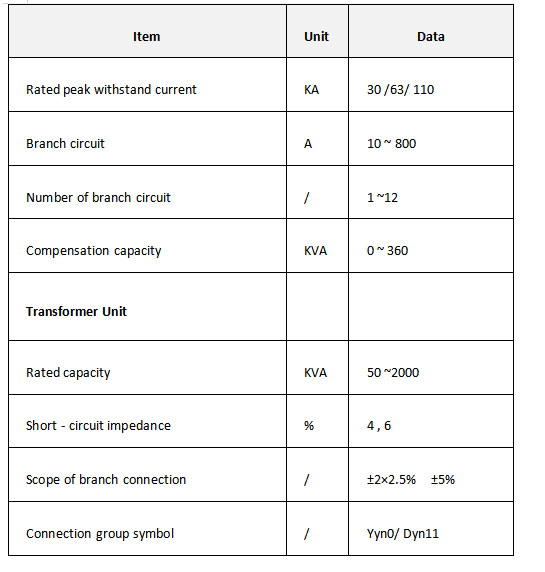

Parameter