| Brand | ROCKWILL |

| Model NO. | 35kV Dry Type Grounding Transformer Cast Resin 3 Phase |

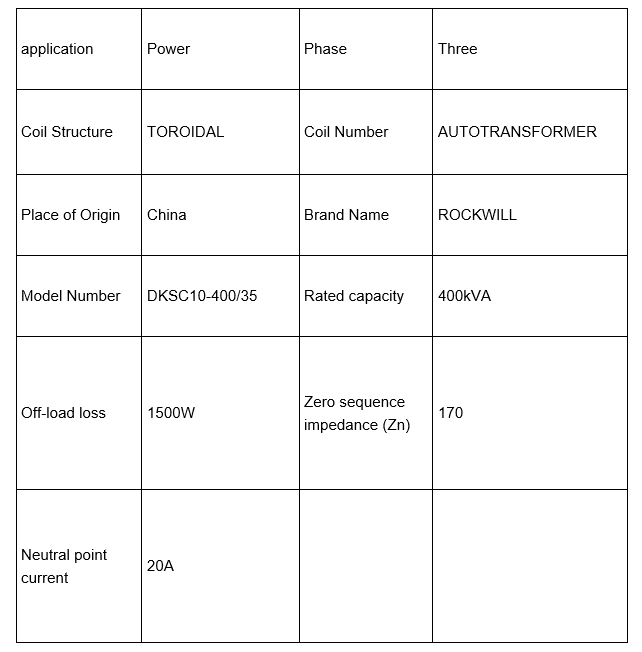

| Rated capacity | 400kVA |

| Phases | 三相 |

| Series | DKSC |

Rockwill Zigzag (Z-Type) Grounding Transformers provide a reliable artificial neutral grounding solution for power systems where the neutral point is unavailable, such as delta-connected or ungrounded star systems. These specialized transformers create a stable neutral point for connecting arc suppression coils (Petersen coils) or neutral grounding resistors, ensuring safe and effective system grounding.

Additionally, Rockwill grounding transformers can be equipped with a secondary winding to supply auxiliary power, offering a cost-effective alternative to separate station transformers.

Key attributes

Substations and distribution networks (35kV and below)

Industrial power systems requiring a neutral grounding point

Renewable energy plants (wind/solar farms) with ungrounded sources

Rated Capacity: 100kVA to 5500kVA

Rated Voltage: Up to 35kV

Insulation Class: Class F (compliant with IEC 60076)

Connection Type: Zigzag (Z-Type) for optimal zero-sequence performance

Zero-Sequence Impedance: Low impedance (~10Ω) for efficient fault current handling

Rockwill grounding transformers deliver superior performance, safety, and cost savings by combining neutral grounding and auxiliary power supply in a single unit. Their optimized design ensures enhanced system protection, reduced downtime, and lower installation costs—making them the ideal choice for modern power systems.