| Brand | POWERTECH |

| Model NO. | 35kV/0.69 kV Compact New Energy Substation for Innovative Wind Energy Applications |

| Rated voltage | 35kV |

| Series | ZGS |

Description

ZGS/ZFS Series American-style box substations feature fully insulated, compact designs with Dyn11 winding for stable power distribution. Ideal for urban and industrial applications, they support ring/radial networks with weatherproof, low-noise operation. These substations feature a fully enclosed, insulated structure that eliminates external insulation distance requirements while maintaining operational safety.

Utilizing a Dyn11 winding configuration, the units provide stable voltage output with effective neutral point grounding. The design incorporates noise reduction measures for low operational sound levels. The compact construction allows for installation in various environments including industrial zones, urban areas, and commercial facilities.

These substations support both ring main and radial network configurations. The modular design facilitates installation and maintenance while ensuring reliable power distribution. The units are constructed with durable materials suitable for long-term outdoor operation under varying climatic conditions.

Standard features include weatherproof enclosures, passive ventilation systems, and accessible cable connection compartments. The design meets typical requirements for urban and industrial power distribution applications, balancing space efficiency with operational reliability.

Features

Compact & Space-Saving Design

High Protection & Durability

Efficient Heat Dissipation & Overload Capacity

Reliable Electrical Components

Environmental Adaptability & Aesthetic Integration

Enhanced Sealing & Protection

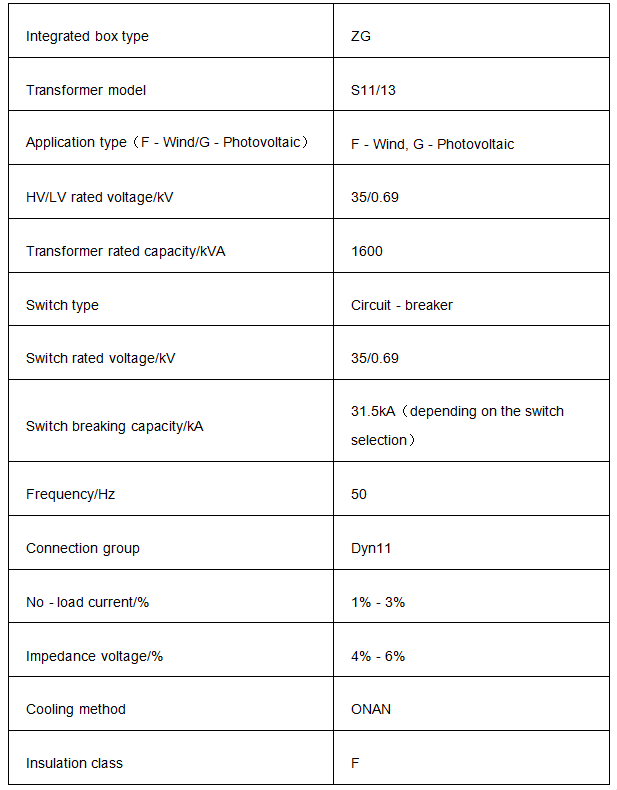

Parameter