| Brand | POWERTECH |

| Model NO. | 30-2000kVA for Electricity Generation Electric Power Prefabricated Compact Box Substation |

| Rated voltage | 12V |

| Series | ZGS-12H |

Description

A substation is a facility that integrates equipment to cut off or switch on circuits, transform or regulate voltage. In the power system, substations serve as hubs for power transmission and distribution, primarily categorized into step-up substations, main grid substations, secondary substations, and distribution substations.

As a vital component of the power system, substations undertake key tasks such as power transmission, transformation, and distribution, playing a critical role in ensuring the stability, safety, and efficiency of China's power supply. Substation products with excellent performance and reliable quality, leveraging advanced technology, have become the preferred equipment for power systems.

American/European-style prefabricated compact box substations with a capacity of 30-2000kVA for power generation are evolving toward a more automated and intelligent future in power equipment development.

The substation integrated automation system employs advanced computer technology, modern electronic technology, communication technology, and information processing technology to reorganize and optimize the functions of secondary equipment in substations (including relay protection, control, measurement, signaling, fault recording, automatic devices, and telecontrol devices, etc.). This comprehensive automation system monitors, measures, controls, and coordinates the operation of all equipment within the substation. By exchanging information and sharing data among (substation) equipment, it completes the task of substation operation monitoring and control. It replaces conventional secondary equipment, simplifies secondary wiring in substations, and serves as an important technical measure to enhance the safe and stable operation level of substations, reduce operation and maintenance costs, improve economic benefits, and provide high-quality power to users.

Integrated System Design

High-voltage switchgear, transformer, and low-voltage switchgear are integrated as a trinity, featuring strong integrity. It offers benefits such as a small footprint, reduced investment, short production cycle, and convenient mobility.

Optimal Layout & Safety

The high and low voltage chambers are reasonably and compactly arranged for easy operation and maintenance. The high-voltage switchgear is equipped with anti-error interlock functions, ensuring safe and reliable operation with simple maintenance.

Diversified Types & Layouts

Available in various types, including multipurpose, villa-style, and compact models. It can be divided into "needle"-shaped and "wood"-shaped layouts to meet different requirements.

Intelligent Temperature Control

The transformer room is equipped with a thermostat that automatically controls the transformer temperature, ensuring the transformer operates at full load efficiently.

Advanced Fault Detection & Automation

An FTU (Feeder Terminal Unit) can be installed in the high-voltage ring network cabinet to reliably detect short-circuit and single-phase ground faults. With "four remote" functions (remote measurement, control, signaling, and regulation), it facilitates the upgrading of distribution network automation.

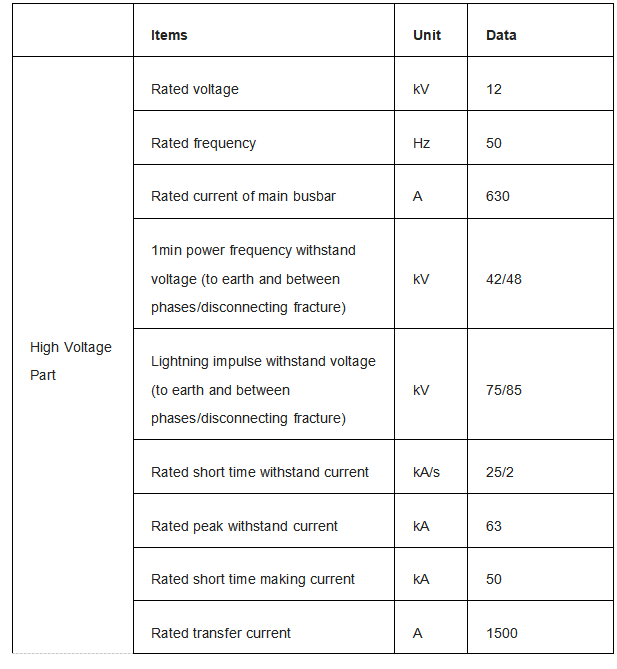

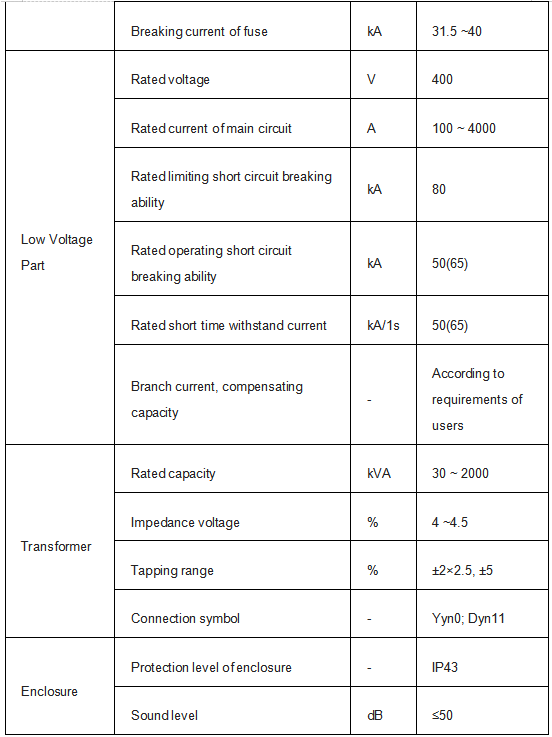

Parameters