| Brand | ROCKWILL |

| Model NO. | 20kV Three Phase Oil-Immersed Earthing Transformer |

| Rated voltage | 20kV |

| Rated capacity | 100kVA |

| Phases | Three-phase |

| Series | JDS |

Product Overview

Rockwill's JDS series oil-immersed earthing transformers provide reliable neutral grounding solutions for 20kV power systems. Designed with robust copper windings and advanced oil-cooling technology, these transformers ensure stable system operation while preventing damage from ground faults.

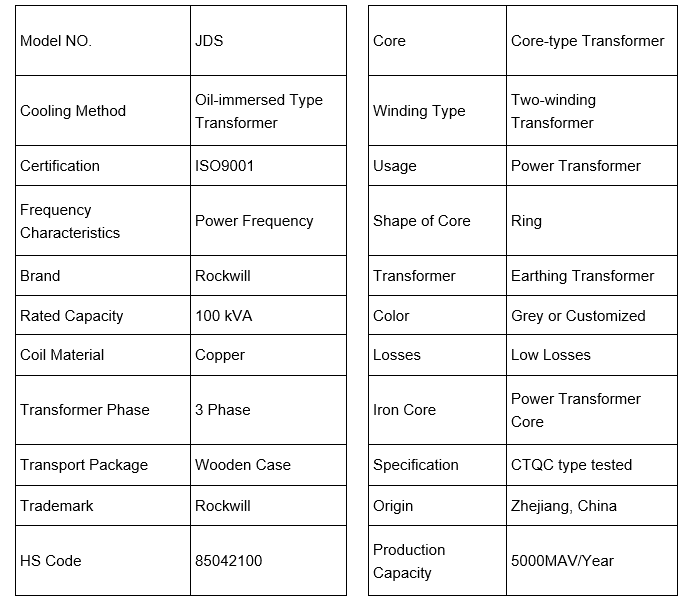

Basic Info

Key Specifications

Model: JDS-100/20

Capacity: 100kVA

Voltage: 20kV

Frequency: 50/60Hz

Winding: Copper two-winding design

Core: Ring-shaped silicon steel

Cooling: ONAN (Oil Natural Air Natural)

Impedance: Low zero-sequence impedance (<10Ω)

Certification: ISO 9001, CTQC tested

Technical Advantages

Superior Grounding Performance

Specially designed winding configuration for optimal neutral point stability

Withstands 100A short-circuit current for 10 seconds

Low zero-sequence impedance ensures effective fault current diversion

Advanced Oil-Cooled Design

Hermetically sealed corrugated tank prevents oil contamination

Mineral oil insulation with -30°C to +40°C operating range

Optional Midel 7131 ester fluid for enhanced fire safety

Robust Construction

Heavy-gauge steel tank with anti-corrosion treatment

Precision-engineered core with reduced magnetic losses

Vibration-resistant mounting system

Smart Protection Features

Standard Buchholz relay for internal fault detection

Pressure relief device for overload conditions

Oil level indicator with alarm contacts

Application Scenarios

Industrial Power Systems

Ideal for manufacturing plants with sensitive equipment

Protects against ground faults in 20kV distribution networks

Suitable for harsh industrial environments

Renewable Energy Installations

Wind farm collector substations

Solar park step-up stations

Biomass power generation facilities

Infrastructure Projects

Metro power supply systems

Airport electrical networks

Hospital backup power systems

Why Choose Rockwill?

20+ years of transformer manufacturing expertise

Custom engineering support available

Complete type test reports provided

Global service network with 24/7 technical support

Environmentally conscious production processes