| Brand | Vziman |

| Model NO. | 2000KVA 11KV 3 Phase Oil-immersed distribution transformer three-phase |

| Rated voltage | 11kV |

| Rated capacity | 2000kVA |

| Series | S |

Description:

Oil immersed transformer ,use our company special calculation and validation procedures to make sure theperformance of products. superior process equipment ,elaborate materialselecting and efficient manufacturing make the transformer have smallvolume,light weight,low loss,low partial discharge,low noise characteristics.

The product is stable,reliable,economic, environmental protection. lt can beapplied to many places such as power plants,transformer substation ,largeindustrial mining and petrochemical enterprise and so on.

Features:

Ultralow no-load loss

Energy saving and great power consuming efficiency

Copper coil winding, strong short circuit resistance ability

Dyn11 coil connection decrease the influences of harmonic wave

Fully sealed structure for maintenance free

Slow insulation aging & longer serving life

Parameters:

Oil-immersed distribution transformer three-phase |

|

Model NO. |

S-2000-11 |

Product classification |

Distribution transformer |

Rated capacity |

2000kVA |

Primary voltage |

11kV |

Secondary voltage |

0.4kV |

Number of phase |

3 |

Number of winding |

2 |

Rated frequency |

50Hz |

Tap changer |

OCTC |

Tap range |

±2×2.5% |

Vector group |

Dyn11 |

Cooling system |

ONAN |

No-load loss |

3250+10% |

Load loss |

16000+10% |

Standard |

IEC60076 |

Impedance |

4.5±10% |

Basic insulation level |

75/28kv |

Winding material ( H.V & L.V) |

Copper |

The way the bushing appears |

Porcelain |

Power frequency withstand voltage |

—— |

Lightning impulse |

—— |

The temperature rise—Winding |

55k |

The temperature rise --Top oil |

65k |

Tank color |

—— |

Creepage distance |

—— |

Environmental requirement |

—— |

Transformer structure |

—— |

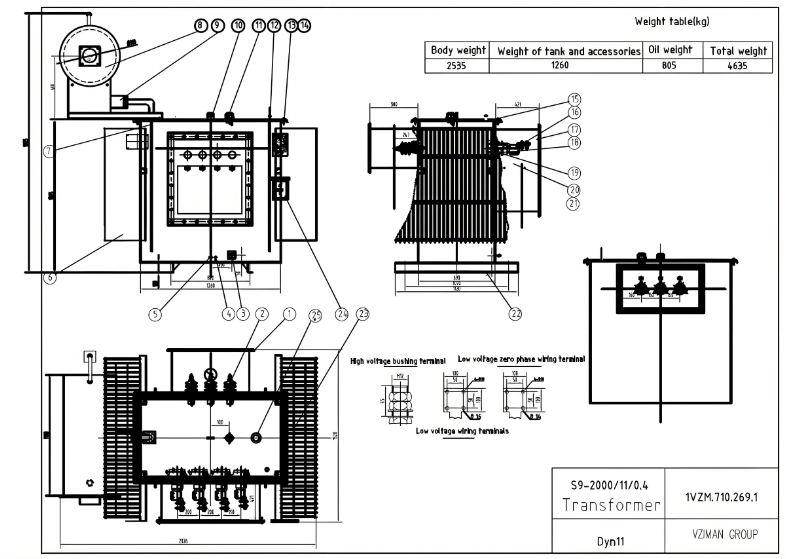

External dimensions:

Size |

2026mm×1520mm×1925mm |

Weight |

2535KG |

External dimensions:

Max. ambient temperature |

|

Altitude |

Product show:

What are the benefits of oil-immersed transformers?

High-Efficiency Heat Dissipation: Oil-immersed transformers use insulating oil as the cooling medium. The thermal conductivity of the oil is much higher than that of air, enabling it to more effectively transfer the heat inside the transformer to the outer surface of the oil tank and then dissipate it into the air through natural convection or forced cooling methods.

Uniform Cooling: The oil can evenly cover the iron core and windings, ensuring a more uniform temperature distribution in each part and reducing the risk of local overheating.

High Insulation Strength: Insulating oil has excellent insulation properties and can provide a higher insulation strength than air, effectively preventing corona discharge and breakdown phenomena and enhancing the operational safety of the transformer.

Extended Lifespan: Good insulation performance can reduce the damage to insulation materials caused by electric field stress, thus prolonging the service life of the transformer.

Stable Operation: Oil-immersed transformers can still operate stably under high-temperature, high-humidity, and harsh environmental conditions, making them suitable for various industrial and commercial application scenarios.

Multiple Protections: Modern oil-immersed transformers are equipped with multiple protective measures, such as gas relays, pressure release valves, and temperature sensors, which can detect and handle abnormal situations in a timely manner to improve safety.

Suitable for High Power: Oil-immersed transformers are suitable for application scenarios with large capacity and high voltage, such as main transformers in power systems and power supply for large industrial equipment.High Efficiency: High-quality winding materials and advanced manufacturing processes make oil-immersed transformers highly efficient, with low losses, energy-saving, and environmentally friendly.