Product Introduction

Versatility with increased reliability and safety

With over 21 years of proven field performance and advanced design, the OVR recloser provides the most reliable recloser for grid modernization and optimization. ABB’s OVR recloser is one of the most flexible devices for network automatic restoration. In addition to reliability improvement and reduction of SAIDI, SAIFI and MAIFI indexes, ABB's OVR recloser can be used as an automatic loadbreak switch or as a sectionalizer. This flexibility in functionality makes the OVR recloser the perfect solution for a smarter grid.

Key features

Key features highlight the product’s innovative design, high-performance capabilities, and operational advantages, ensuring optimal suitability for diverse industrial and power system requirements.

- Gang-operated three-phase tripping

- RER615 2.0 ABB Relion® Protection

- Optionally available with SEL 751 IED with basic Feeder protection functionalities, offering flexibility in protection relay selection

- Integrated current and voltage measurement

- Also reliable in extreme conditions like high polluted environments

- Rated at up to 38 kV, 16 kA solid dielectric

- High-impedance fault detection

- IEC61850 native: communication protocol flexibility: IEC 61850, Modbus and DNP or IEC 61850 and IEC 101/104

- Standard web browser used to check the current system status of an ABB Relion® relay

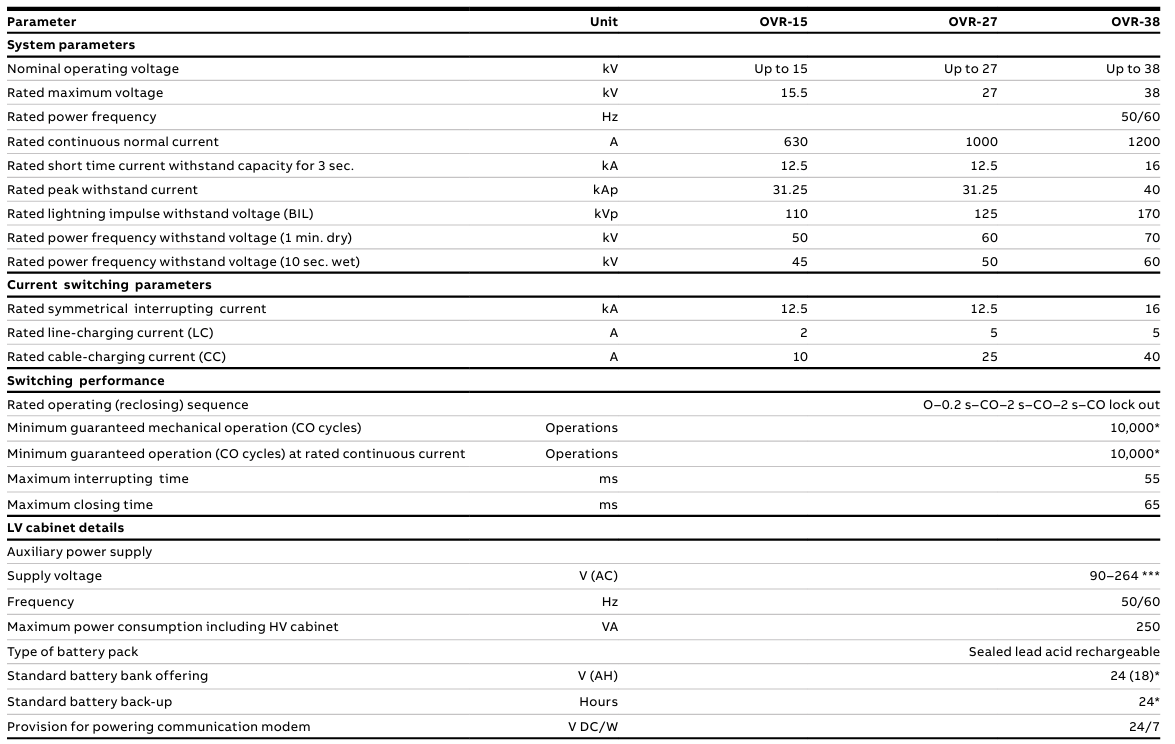

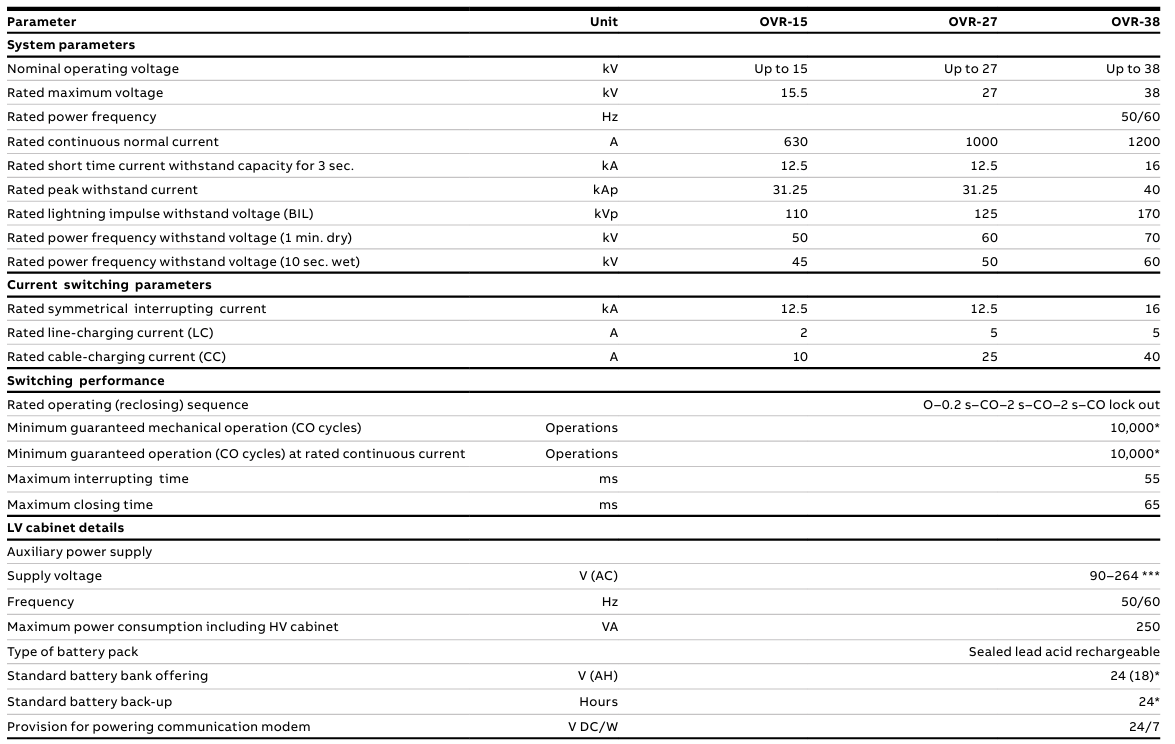

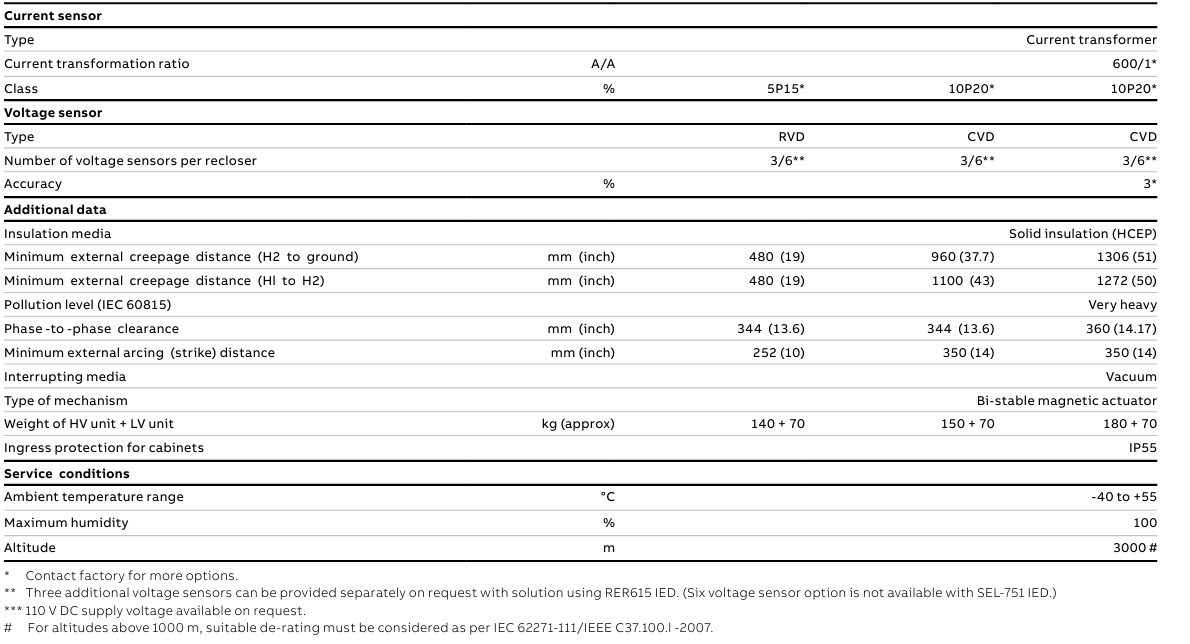

Technical data

Key benefits underscore the product’s reliability, efficiency, and cost-effectiveness, delivering tangible value for power distribution and industrial applications.

Key benefits

Key benefits underscore the product’s reliability, efficiency, and cost-effectiveness, delivering tangible value for power distribution and industrial applications.

- Increased reliability - the highest creep distance among the recloser poles on the market ensures long-term performance in any environment

- Unparalleled performance - the HCEP (Hydrophobic Cycloaliphatic Epoxy) material of the poles provides the best insulation for outdoor use, shedding water and debris, thus reducing the probability of flashovers even in heavily polluted areas

- Simple, fast and safe maintenance as all the electronics are in the low-voltage range, eliminating the need for a bucket truck to isolate potentials to service electronics

- Easy integration with ABB Relion® protection RER615 2.0, capable of programming grid applications. Optionally available with SEL 751 IED with basic Feeder protection functionalities.

- Solid dielectric recloser: ABB vacuum interrupters and sensors embedded in each recloser pole