| Brand | ABB |

| Model NO. | 15.5kV 27.7kV 38kV Solid dielectric single-triple-phase recloser |

| Rated voltage | 38kV |

| Rated normal current | 1250A |

| Rated frequency | 50/60Hz |

| Series | GridShield® |

The ABB GridShield® recloser is a flexible solution that minimizes operation and maintenance costs through extensive research and testing for optimal outdoor performance. Integrating the ABB solution in the grid is quick and easy as it can be paired with a choice of controllers - ABB RER620,ABB RER615, SEL651R, Beckwith M-7679.

Highly reliable and technically adept, whether performing three- or single-phase tripping, the GridShield® recloser is ready for any challenge and geared to support the different needs of the distributed and smart grid of tomorrow. ABB reclosers are suitable for various applications, including feeder protection, loop control, etc. and allow full flexibility of use and superior results in fault detection isolation and restoration.

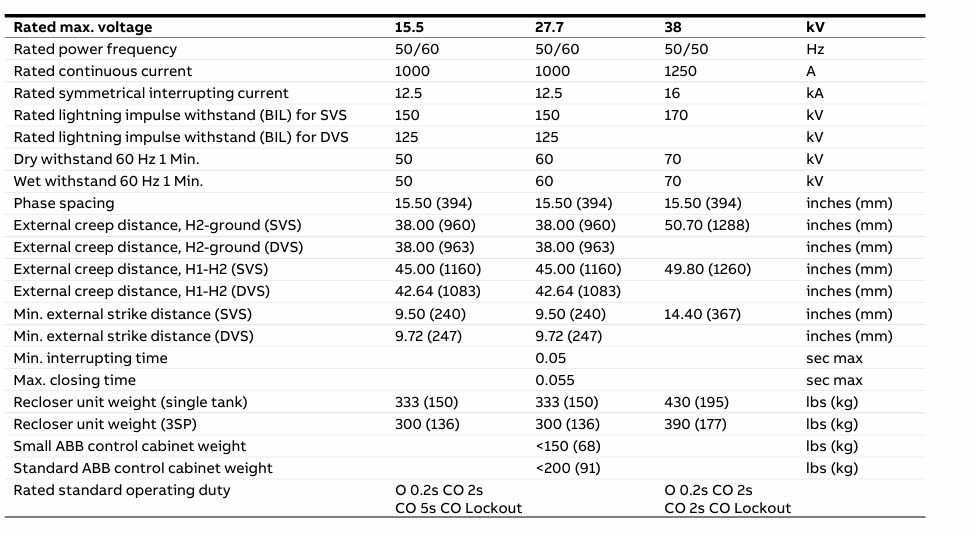

The following table details the key technical specifications of the product, comprehensively covering electrical performance, mechanical characteristics, and dimensional parameters to provide a clear reference for technical selection and application scenarios.

Key features

The product offers multiple significant advantages, which can fully meet the diverse needs of industrial and power systems. Specifically included are:

Key benefits