| Brand | POWERTECH |

| Model NO. | 100 - 1250kVA Compact Prefabricated Substation (European Type) |

| Rated voltage | 10kV |

| Series | YB-10 |

Prefabricated substations are integrated power distribution solutions that combine high-voltage switchgear, transformers, and low-voltage switchgear into a compact, modular unit. These systems are widely employed in urban high-rise buildings, residential complexes, industrial parks, small and medium-sized factories, mining operations, highway projects, and temporary construction sites for efficient power distribution.

Notable for their high integration, compact design, and reliable performance, prefabricated substations offer advantages such as simplified maintenance and portability. Compared to traditional civil substations, they occupy only 1/10 to 1/5 of the space for equivalent capacity, significantly reducing design complexity, construction workload, and overall costs.

Versatile in application, these substations can be integrated into ring-network power distribution systems, dual-power supply setups, or radial terminal distribution networks. As a modern and efficient solution, they are increasingly favored for urban and rural power grid upgrades, representing a new generation of compact substation technology.

This integrated power distribution system consists of three key functional compartments: the high-voltage room, transformer room, and low-voltage room, each designed for optimal performance and flexibility.

High-Voltage Room

Supports multiple power supply modes, including ring network, terminal, and dual-power supply configurations.

Equipped with high-voltage metering for precise energy measurement when required.

Compact and logically structured, featuring a comprehensive anti-misoperation interlock system for enhanced safety.

Transformer Room

Compatible with oil-immersed or dry-type transformers based on user needs.

Optional rail installation allows smooth transformer movement via side doors.

Equipped with automatic temperature-controlled ventilation (natural & forced airflow) to ensure stable operation.

Low-Voltage Room

Customizable panel or cabinet-mounted structures to meet diverse power distribution needs.Integrates power distribution, lighting control, reactive power compensation, and energy metering for a complete solution.Enhances power supply management efficiency while improving overall power quality.

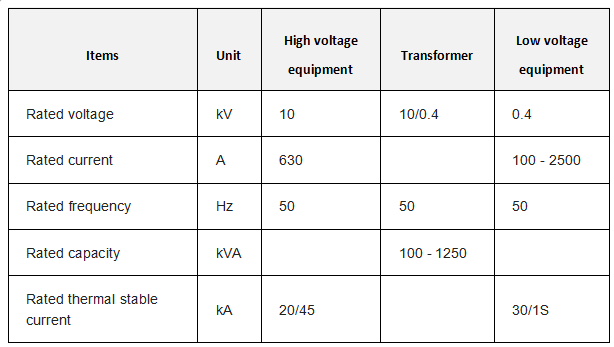

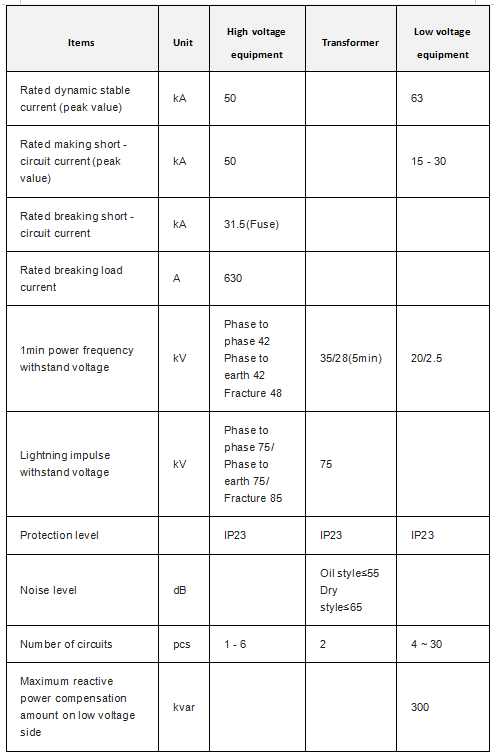

Parameter

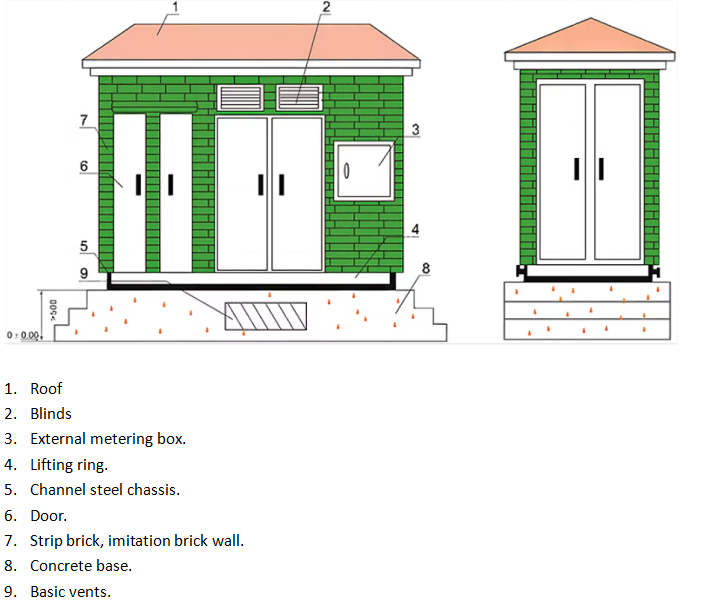

Structural diagram