High - voltage circuit breakers are used to connect or cut off load currents during normal operation. When a short - circuit fault or severe over - load occurs in electrical equipment or lines, a relay protection device controls them to automatically and quickly cut off the fault current, isolating the equipment or lines with the short - circuit fault to prevent the expansion of the accident scope.

Throughout the development of high - voltage circuit breakers, from oil - filled circuit breakers and compressed - air circuit breakers to SF₆ circuit breakers and vacuum circuit breakers, each step has been a major innovation in arc - extinguishing principles. Among them, SF₆ circuit breakers have advantages such as strong interrupting capacity, long electrical life, high insulation level, and good sealing performance, and are most widely used in high - voltage environments currently.

SF₆ circuit breakers (hereinafter referred to as circuit breakers) are important equipment in high - voltage power transmission. Insulation performance and interrupting performance are the main technical indicators for evaluating circuit breakers. SF₆ circuit breakers are a type of circuit breaker using an insulating medium. Along with air - circuit breakers, they belong to gas - blast circuit breakers and rely on SF₆ gas for insulation. SF₆ gas has a high thermal conductivity, can recombine after decomposition, and does not contain harmful insulating substances like carbon. When the water content is strictly controlled, the decomposition products are non - corrosive. The insulation performance of SF₆ gas does not decline with use, so it maintains good insulation performance even after multiple interruptions.

Pure SF₆ gas is an excellent arc - extinguishing medium. Due to its superior arc - extinguishing and insulating properties, it was successfully applied to high - voltage and extra - high - voltage electrical equipment in the 20th century. Currently, SF₆ is the optimal gas insulating medium, especially in the high - voltage and extra - high - voltage ranges, where it is the sole insulating and arc - extinguishing medium. To ensure the stable interrupting performance of circuit breakers, the SF₆ gas inside circuit breakers is required to have a purity of 99.99%.

Because the gas chamber of SF₆ circuit breakers is relatively large, there are many connecting pipes, and there are numerous sealing surfaces inside the circuit breakers. During operation, issues such as insufficient SF₆ pressure may occur due to sealing problems or temperature changes. In practical applications, due to factors like operational vibrations and poor sealing, the probability of gas leakage in circuit breakers exceeds the factory - set annual leakage rate of 1%. Therefore, circuit breakers often need to be refilled with gas.

This article introduces a new type of non - disassembly SF₆ circuit breaker detection, gas - filling, and gas - supplementing device. It can perform micro - water detection of circuit breakers and calibration of density relays through instruments without power outages. It can also expel air, moisture, and impurities in the gas - filling pipes during gas - filling and gas - supplementing processes. Additionally, it can automatically relieve pressure and give an alarm when the gas pressure exceeds the rated value during the gas - filling process.

1 Current Situation in China

Currently, domestic gas - supplementing devices for circuit breakers typically involve installing a combined valve on the circuit breaker. This combined valve, which consists of a valve body, a gas - supplementing interface, a circuit breaker interface, and a density relay interface, can be connected to a micro - water meter and a density relay calibrator. This effectively addresses the issue of having to cut off power when measuring the micro - water content of the circuit breaker and calibrating the density relay, thereby enhancing work efficiency and reducing damage to the circuit breaker during disassembly.

However, it fails to solve the problem of air, moisture, and impurities in the gas - filling pipes entering the circuit breaker during the gas - filling and gas - supplementing processes. During the gas - filling and gas - supplementing operations of existing circuit breakers, the SF₆ gas - filling cylinder is directly connected to the circuit breaker via a pressure - reducing valve and a gas - supplementing hose. As a result, the SF₆ gas entrains air, moisture, and impurities from the hose into the circuit breaker. This reduces the purity of the SF₆ gas, degrades its insulation performance, damages the circuit breaker, and shortens its service life.

As a protective device for the power system, strict regulations and requirements have been imposed on SF₆ gas used in high - voltage electrical equipment. Once the water content in SF₆ circuit breakers reaches a certain level, it can lead to serious adverse consequences. Moisture can cause the decomposition products of SF₆ gas to undergo chemical reactions, generating toxic compounds; it can cause chemical corrosion of equipment; it is detrimental to the insulation of equipment; it affects the interrupting performance of switches; and it reduces the mechanical performance of switches.

Currently, when conducting micro - water detection and density relay calibration on circuit breakers, the circuit breaker must be disassembled after power outage. This not only impacts production but also affects the sealing performance of the circuit breaker. Frequent disassembly also impairs the accuracy of the relay.

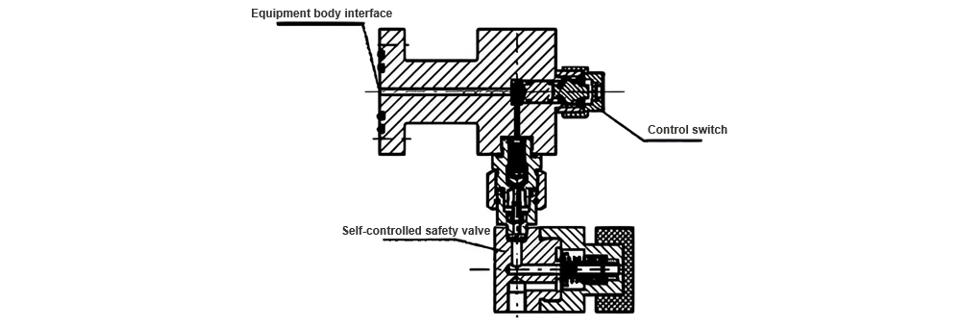

2 Working Principle and Structural Design

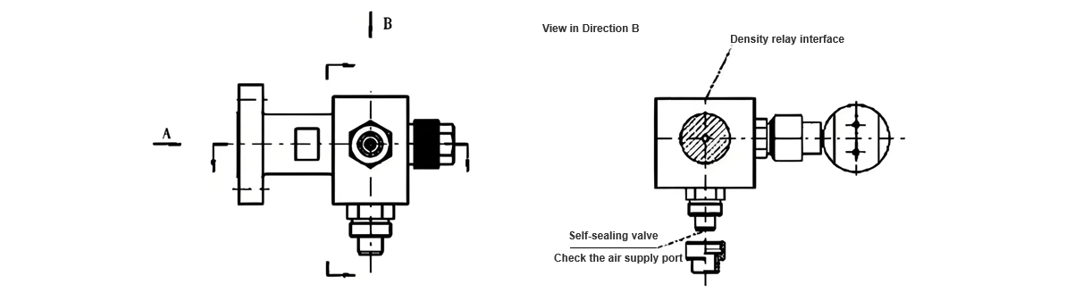

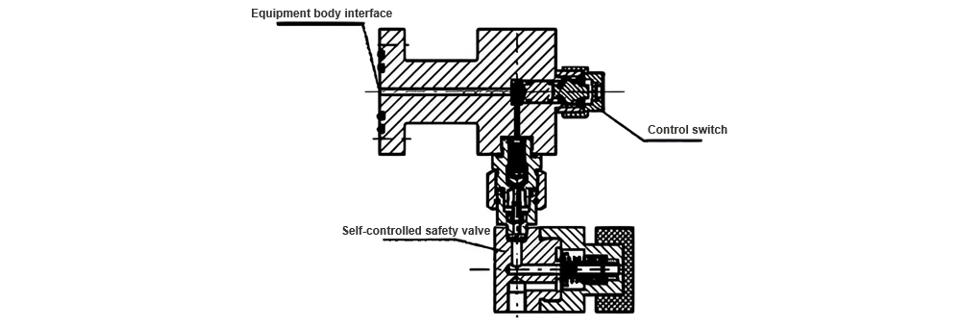

The SF₆ circuit breaker detection, gas - filling, and gas - supplementing device includes a valve body, a self - sealing valve, a self - controlled back - pressure valve, and a control switch, as shown in the structure diagram. This device organically integrates the valve body with the self - sealing valve, the self - controlled back - pressure valve, and the control switch. One end of the valve body is fixedly equipped with a circuit breaker connection plate, the other end is fixedly equipped with a control switch. The valve body is also fixedly equipped with a self - sealing valve, a self - controlled back - pressure valve, and a density relay interface. The control switch controls the opening and closing of these valves.

The SF₆ circuit breaker detection, gas - filling, and gas - supplementing device introduced in this article, by organically integrating the valve body with the self - sealing valve, the self - controlled back - pressure valve, and the control switch, integrates micro - water measurement, density relay calibration, and gas - filling and gas - supplementing operations of circuit breakers without power outages. Before gas - filling and gas - supplementing operations, it can automatically expel air, moisture, and impurities in the gas - supplementing system. During the gas - filling and gas - supplementing operations of the circuit breaker, it can achieve pressure detection and pressure - relief alarm. It is applicable to imported SF₆ circuit breakers with a voltage above 110 kV, Alstom FXT11 - type circuit breakers from France, and domestic SF₆ circuit breakers with a voltage above 110 kV. It can withstand high pressure, ranging from 0.5 to 16 MPa, and is safe and reliable.

- Remove Impure Gas: Connect the SF₆ gas cylinder to the self - sealing valve of this device through a pressure - reducing valve, a gas - supplementing hose, and a connector. Close the control switch and open the valve of the SF₆ gas cylinder. SF₆ gas enters the device through the gas - supplementing hose. At this time, impurities such as air in the pipe also enter the circuit breaker along with the SF₆ gas. The gas in the device is a mixture of SF₆ gas and air impurities. When the pressure in the device exceeds the set pressure of the self - controlled back - pressure valve, the self - controlled back - pressure valve automatically opens and discharges gas for 8 - 10 seconds. During this exhaust process, all the air and impurities in the entire system are removed. Then, close the valve of the SF₆ gas cylinder. When the pressure in the system is consistent with the set pressure, the self - controlled back - pressure valve automatically closes, completing the air and impurity removal operation. At this point, the purity of the SF₆ gas in the system is the same as that in the gas cylinder, and it is qualified gas.

- Gas - Filling and Pressure - Supplementing: With the entire system filled with pure SF₆ gas after the impurity removal process, open the control switch of this device, and then open the valve of the SF₆ gas cylinder to supplement gas to the circuit breaker. When the pressure in the circuit breaker exceeds the pressure set by the self - controlled back - pressure valve, the self - controlled back - pressure valve automatically opens, alarms, and discharges gas. At this time, close the valve of the SF₆ gas cylinder. When the pressure reaches the set value, the self - controlled back - pressure valve automatically closes, completing the gas - supplementing operation. After the operation is completed, remove the connector connected to the gas cylinder from the self - sealing valve of this device.

- Automatic Alarm and Pressure Control: During the gas - filling process, the self - controlled back - pressure valve plays a role in monitoring the pressure. Once the pressure exceeds the set value, it will automatically open, alarm, and discharge gas to ensure that the pressure in the circuit breaker does not exceed the safe range.

- Gas - Supplementing and Pressure Measurement: After the gas - supplementing operation, the pressure in the circuit breaker can be monitored to ensure that it reaches the required value.

When performing micro - water measurement, connect the micro - water measuring instrument to the self - sealing valve. Open the switch of the micro - water measuring instrument, allow the gas in the system to enter the micro - water measuring instrument, then close the switch of the measuring instrument for detection. After the detection, remove the micro - water measuring instrument to complete the micro - water measurement operation. There is no need to cut off the power during the detection process.

When performing density relay calibration, close the control switch of the device, connect the density calibrator to the self - sealing valve for calibration work. After the work is completed, remove the density calibrator and open the control switch. There is no need to cut off the power during the detection process.

The non - disassembly SF₆ circuit breaker detection, gas - filling and gas - supplementing device integrates micro - water measurement, density relay calibration, and gas - filling and gas - supplementing operations of the circuit breaker through instruments without power outages. Before gas - filling and gas - supplementing operations, it can automatically remove air, moisture, and impurities in the gas - supplementing system. During the gas - filling and gas - supplementing operations of the circuit breaker, it can achieve pressure detection and pressure - relief alarm. It is convenient and quick to operate and does not affect the normal operation of the circuit breaker.

3 Conclusion

The non - disassembly SF₆ circuit breaker detection, gas - filling and gas - supplementing device can completely remove air, moisture, and impurities in the gas - supplementing pipe and the system before gas - supplementing for the circuit breaker. Moreover, during the gas - filling process, when the gas pressure in the system reaches the rated value, it can automatically exhaust gas and alarm. This device is equipped with a system control switch, enabling micro - water measurement and density relay calibration operations without power outages. It is convenient and quick to operate and does not affect the normal operation of the circuit breaker. It is applicable to imported SF₆ circuit breakers with a voltage above 110 kV, Alstom FXT11 - type circuit breakers from France, and domestic SF₆ circuit breakers with a voltage above 110 kV. It can withstand high pressure, ranging from 0.5 to 16 MPa, and is safe and reliable.