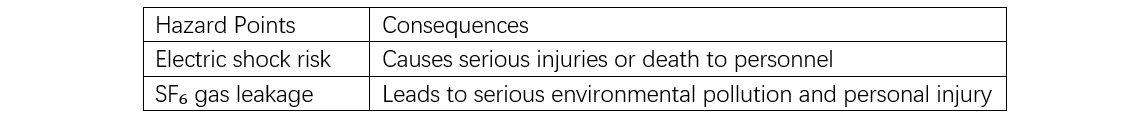

1.1 Electric Shock Risk

In the substation maintenance site of high - voltage SF₆ circuit breakers, the risk of electric shock is an extremely serious safety hazard. Electric shock can not only cause serious injuries or death to personnel but also trigger other severe secondary accidents. Therefore, constant vigilance is required, and a comprehensive analysis and prevention of the electric shock risk are necessary.

Firstly, high - voltage equipment itself has an extremely high voltage level. Once a person touches a live part, it can lead to extremely dangerous electric shock accidents. Especially during the maintenance process, some components of the equipment may be exposed. If an operator accidentally contacts them with tools, it may result in injuries at best and loss of life at worst. Additionally, the grounding devices and metal pipelines around the equipment may carry induced voltages, posing potential electric shock hazards.

Secondly, the internal environment of a substation is complex, with various high - and low - voltage lines and equipment densely distributed, and multiple power sources present. Moreover, in the maintenance operation area, there may be situations where the power supply cannot be completely cut off, and there is still a certain residual voltage. If the operation is improper, it may trigger an electric shock accident.

Thirdly, static electricity generated during the maintenance process is also a non - negligible source of electric shock risk. Generally, when an SF₆ circuit breaker opens and closes, a large amount of static charge may accumulate. If the operator does not take effective protective measures, they may be electrocuted due to static discharge when touching conductive parts.

Finally, adverse environmental factors such as a wet maintenance site and a narrow space also increase the risk of human body leakage and induced voltage, intensifying the danger of electric shock.

1.2 SF₆ Gas Leakage

In the substation maintenance site of high - voltage SF₆ circuit breakers, SF₆ gas leakage is a significant safety hazard that cannot be ignored. SF₆ is an inert gas. Although it is non - toxic and harmless in itself, a large - scale leakage may lead to serious environmental pollution and personal injury.

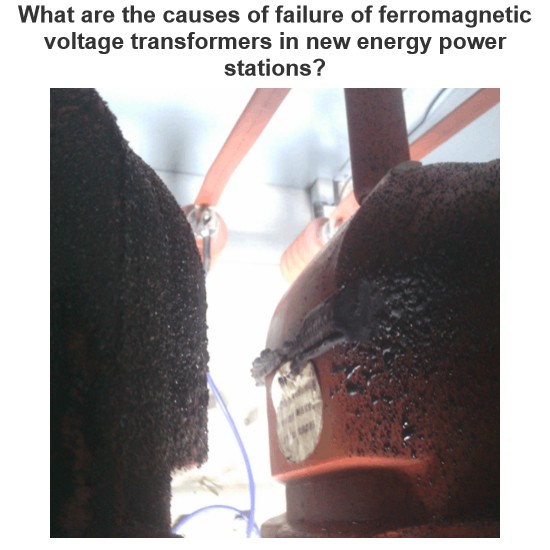

Firstly, the sealing performance of SF₆ circuit breakers is crucial for preventing gas leakage. However, during long - term operation and maintenance, seals may develop tiny gaps due to wear and aging, resulting in a small amount of SF₆ gas leakage and reducing the sealing effect. If the problem is not detected and addressed in a timely manner, the leakage point will expand, eventually leading to a large - scale SF₆ leakage.

Secondly, during the maintenance process, operations such as disassembly and assembly of SF₆ circuit breakers are required. There is a risk of serious gas leakage due to human operational errors. For example, if the internal SF₆ gas is not released in accordance with the regulations during disassembly and assembly, or if the fixation is not in place and the gas chamber falls off, it may directly trigger a large - area leakage accident.

Finally, after SF₆ gas leaks, it will accumulate in low - lying areas or enclosed spaces to form high - concentration areas. If workers accidentally enter these areas, they may experience suffocation, poisoning, etc. Especially in a narrow maintenance site environment, gas accumulation is more severe, and the harm of leakage is amplified.

2 Analysis of Safety Control Technologies for Substation Maintenance Based on High - voltage SF₆ Circuit Breakers

2.1 Standardization of Operating Procedures

High - voltage SF₆ circuit breakers are vital equipment in the power system, and their safe and stable operation is directly related to the overall performance and reliability of the power grid. To ensure the safety of high - voltage SF₆ circuit breakers during substation maintenance, it is of great importance to develop a scientific, standardized, and practical set of operating procedures for safety control technologies.

The standardization of operating procedures plays a crucial role in ensuring the safety of substation maintenance operations based on high - voltage SF₆ circuit breakers. Standardized operating procedures not only serve as a standard basis for guiding maintenance work but also provide a fundamental guarantee for preventing various safety risks. Standard operating procedures should not only specify detailed operation steps but also provide clear guidance for all aspects of maintenance management, such as general requirements for qualification review and tool inspection, ensuring that the entire operation process is under reliable control.

In addition, operating procedures should be targeted and operable. Different procedures need to be developed for SF₆ circuit breakers of different voltage levels and models. For different types of maintenance, such as daily inspections and defect repairs, targeted requirements should also be set. The content of the procedures should be clearly expressed and the steps should be concise to facilitate better understanding and implementation by operators.

2.2 Power - off and Grounding Measures

Power - off and grounding measures are key technical links to ensure the safety of substation maintenance operations based on high - voltage SF₆ circuit breakers. They are crucial for preventing serious accidents such as electric shock and static electricity release.

Power - off operations are the primary preparatory work before maintenance. Maintenance personnel must first cut off all possible power sources of the maintenance object and its surrounding areas in accordance with the operating procedures to ensure that the operation area is completely powered off, fundamentally eliminating the risk of live - line work. At the same time, to avoid incomplete power - off due to misoperation, dual measures are usually taken, such as disconnecting the load switch or disconnecting switch and confirming the power - off state through testing, such as using a voltage tester.

For the powered - off maintenance object and its ancillary facilities, reliable grounding is required to avoid induced voltages and static electricity release. By connecting the conductor to the earth potential, induced voltages and static electricity can be released, thus eliminating the hidden danger of electric shock. When grounding, the sequence of "ground first, operate later, evacuate first, and remove later" should be followed to ensure the safety of personnel in each link.

Grounding measures generally need to be reliable and redundant. Special grounding wires should be used to connect to the grounding device. All metal bodies that may be charged should be grounded. At the same time, the grounding wires should have sufficient current - carrying capacity, and the number should be appropriately redundant to avoid single - point failure. For some equipment that cannot be grounded directly, indirect grounding measures such as equipotential bonding or local grounding should be adopted.

2.3 SF₆ Gas Monitoring and Management

The monitoring and management of SF₆ gas are of great importance for ensuring the safety of operations at the substation maintenance site based on high - voltage SF₆ circuit breakers. SF₆ is an inert gas. Although it is non - toxic and harmless in itself, a large - scale leakage can cause serious harm to the environment and human health. Therefore, a complete SF₆ gas monitoring and management system must be established to prevent leakage risks from the source.

Firstly, regularly detect the sealing performance of SF₆ circuit breakers. Use advanced means such as infrared thermal imagers and acoustic detection to accurately identify tiny cracks and leakage points and repair them in a timely manner, and replace the seals to ensure the overall sealing performance of the equipment. At the same time, strictly follow the operating procedures during maintenance disassembly and assembly, and operate with extra caution to avoid serious leakage caused by human error.

Secondly, a comprehensive SF₆ leakage detection system should be deployed in the substation. Fixed or mobile monitoring devices should be installed in the maintenance site and other key areas to monitor the change in SF₆ concentration in real - time. Once an abnormality is detected, the system should issue an alarm in a timely manner. At the same time, the monitoring system should have remote monitoring and data storage functions to enable maintenance personnel to better grasp the on - site situation.

Thirdly, relevant departments should formulate a complete SF₆ gas management system and clarify the handling process when the monitoring values are abnormal. When a certain concentration of SF₆ leakage is detected, relevant personnel should immediately activate the emergency plan, cut off the leakage source in a timely manner, and isolate and evacuate the affected area to prevent further gas diffusion. At the same time, mobilize emergency resources, such as ventilation facilities, to purify the on - site environment as soon as possible.

Finally, strengthening the training and education of maintenance personnel is also an important part of SF₆ gas management. Through training, maintenance personnel can fully understand the hazards of SF₆ leakage and master prevention and response measures. At the same time, organize emergency drills regularly to test the pertinence and operability of the management system and continuously improve it.

3 Conclusion

In high - voltage power systems, SF₆ circuit breakers, as key switching equipment, are crucial for the stable operation of the entire system in terms of safety and reliability. However, due to various potential hazard points during the operation of SF₆ circuit breakers, such as SF₆ gas leakage, high voltage and arcs, mechanical device failures, and conductive part risks, scientific maintenance and strict safety control are of great significance.

This paper studies the hazard points and safety control technologies at the substation maintenance site based on high - voltage SF₆ circuit breakers, which is essential for ensuring the safety of maintenance personnel. In actual operations, maintenance personnel should strictly abide by relevant safety operation regulations and conduct regular safety training and drills to improve their ability to respond to emergencies. At the same time, equipment maintenance units should continuously optimize maintenance processes, improve corresponding measures, and adopt advanced safety technologies to ensure the efficient and safe implementation of maintenance work.

In the future, the research on hazard points and safety control technologies at the substation maintenance site of high - voltage SF₆ circuit breakers will develop towards intelligence, refinement, and environmental friendliness. By introducing advanced technologies and optimizing maintenance processes, the efficiency and safety of maintenance work can be further improved, providing a more reliable guarantee for the stable operation of the power system. Moreover, with the continuous progress and innovation of science and technology, it is reasonable to believe that the future substation maintenance technology for high - voltage SF₆ circuit breakers will be more advanced and perfect.