High - voltage circuit breakers are one of the most crucial control appliances in the power system. The operation status of high - voltage circuit breakers directly affects the safe and stable operation of the power system. Among them, the outdoor porcelain post type SF₆ circuit breaker is one of the main types of high - voltage circuit breaker. SF₆ has a high electrical withstand strength, excellent arc - extinguishing performance, and insulation capability. However, in practical applications, it has been found that in severely cold areas such as Zhangjiakou Bashang in Hebei Province, low temperatures can easily cause the liquefied SF₆ gas, resulting in a decrease in the pressure of SF₆ gas. This may trigger a low - pressure alarm for the circuit breaker or even lead to a lockout (circuit breaker lockout means that the circuit breaker can neither close nor open), seriously affecting the breaking capacity and insulation performance of the circuit breaker. To address this issue, this paper designs a gas heating device for the 110kV porcelain post type SF₆ circuit breaker.

1 Low - pressure Alarm and Lockout Situation of the Porcelain Post Type SF₆ Circuit Breaker

In the Bashang area of Zhangjiakou, the winter temperature can reach - 30 °C. The low - pressure alarm and even lockout faults of SF₆ circuit breakers have occurred multiple times in substations in the Bashang area. In just one month, the low - pressure alarm occurred more than 30 times, and the lockout fault occurred more than 10 times, posing a great potential threat to the safe and stable operation of the power grid. Research has shown that the primary cause of the alarm and lockout faults in the 110kV porcelain post type SF₆ circuit breaker is the absence of an SF₆ gas heating device. Since the SF₆ gas chamber is directly exposed to the external environment, when the ambient temperature drops to a certain level, the SF₆ gas will liquefy, causing the pressure in the gas chamber to be lower than the specified alarm and lockout pressure values.

2 Problems with Traditional Solutions

Currently, the main methods for solving the low - pressure alarm and lockout problems of the porcelain post type SF₆ circuit breaker are as follows:

(1) Inflating the circuit breaker to increase the molecular weight of the gas in the tank, thereby increasing the pressure of the SF₆ gas. However, this method is not applicable in extremely cold weather. Because the supplemented SF₆ gas will quickly liquefy under low temperature and high - pressure environments, and it is still impossible to increase the gas pressure. The rated pressure of SF₆ in the circuit breaker is generally 0.6 MPa, and the saturated vapor pressure of SF₆ is 0.6 MPa at - 20 °C. As the ambient temperature decreases, the saturated vapor pressure of SF₆ will drop. That is to say, in an extremely low - temperature environment, even if the circuit breaker is inflated, due to the saturated vapor pressure of SF₆ gas, the inflated gas will quickly liquefy, and the purpose of increasing the pressure cannot be achieved. Therefore, when the ambient temperature is lower than - 20 °C, this method cannot restore the rated pressure inside the circuit breaker.

(2) Manually disconnecting the lockout circuit of the circuit breaker to enable the circuit breaker to close and open normally. However, this method causes the circuit breaker to lose the protection of the electrical lockout. Once the gas pressure inside the circuit breaker fails to meet the requirements for arc extinguishing or even insulation, serious accidents may occur, and the labor cost is relatively high.

(3) Using the method of heating the SF₆ gas to solve the problem of liquefaction of the arc - extinguishing medium of the SF₆ circuit breaker in cold regions. According to the specific structure of the circuit breaker, a corresponding heating device is customized, and the operating temperature of the SF₆ gas is increased through heating to avoid the liquefaction of the SF₆ gas in a low - temperature environment. The gas heating device of the circuit breaker can generally automatically activate or deactivate the heating function according to the change of the ambient temperature. The operation and maintenance personnel can set the automatic activation and deactivation temperature setting values according to the actual ambient temperature. Compared with manually disconnecting the lockout circuit of the circuit breaker, this method reduces the labor cost in operation and maintenance. However, the installation of the heating device requires high human and material costs, and the thermal utilization rate is relatively low.

3 Heating Device for the Porcelain Post Type SF₆ Circuit Breaker

According to the structural characteristics of the porcelain post type SF₆ circuit breaker, a heating device for the porcelain post type SF₆ circuit breaker is designed, which includes three parts: the heating module, the temperature control module, and the power supply module.

3.1 Heating Module

The installation location of the heating device is of great importance, directly affecting the heating efficiency of the SF₆ gas. The porcelain post type circuit breaker is composed of multiple basic units, including the arc - extinguishing chamber, the support porcelain bushing, the operating mechanism, the support frame, etc. There are two interconnected support porcelain bushings below the arc - extinguishing chamber, which are filled with SF₆ gas. The main function of the support porcelain bushing is to achieve insulation against the ground. Therefore, when designing the porcelain post type circuit breaker, a certain insulation distance must be maintained, and the mechanical strength of the ceramic material must be ensured. This means that it is not possible to install a conductive heating device on the outer surface of the porcelain bushing [5]. In this paper, the heating part is selected as the transmission chamber. However, the transmission chamber has an irregular shape, and traditional heating devices are not easy to be fixed. Moreover, the transmission chamber is located in the base of the porcelain post type circuit breaker, and the space is narrow. Traditional heating devices are too large in size, which may affect the normal operation of the transmission mechanism of the circuit breaker.

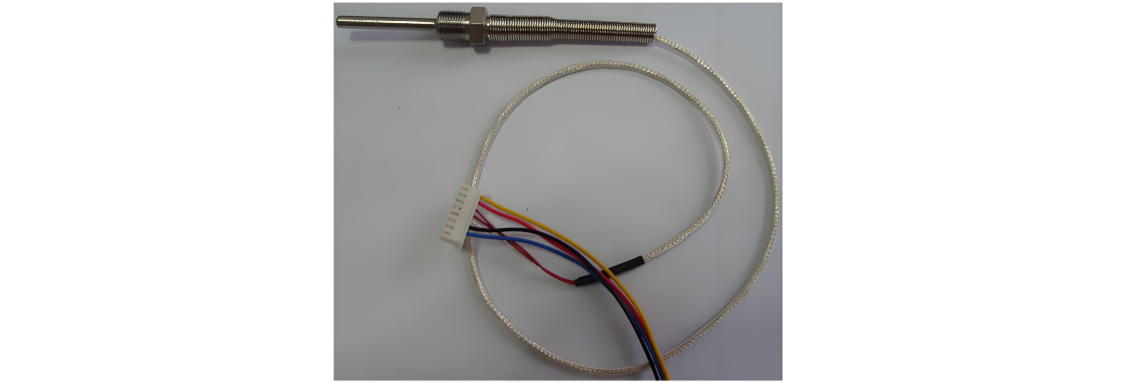

A heating module is designed according to the characteristics of the porcelain post type circuit breaker in the Zhangjiakou Bashang area. The heating module is composed of a heating tape and a resistance wire. The heating tape is made of insulating silicone rubber, and the back adhesive is 3M heat - resistant adhesive, with the outlet on the front, as shown in Figure 1. The resistance wire is wrapped inside the heating tape. The heating tape made of insulating silicone rubber and the 3M heat - resistant adhesive can withstand high temperatures (the voltage is AC220V), and the shape and length of the heating tape can be flexibly selected according to the shape of the transmission chamber of the on - site circuit breaker.

Figure 1 shows the front and back sides of the heating module

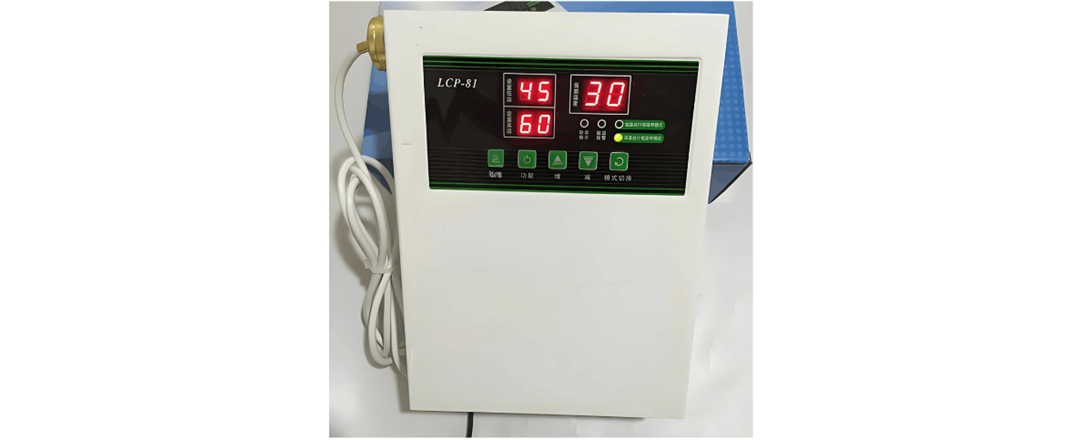

3.2 Temperature Control Module

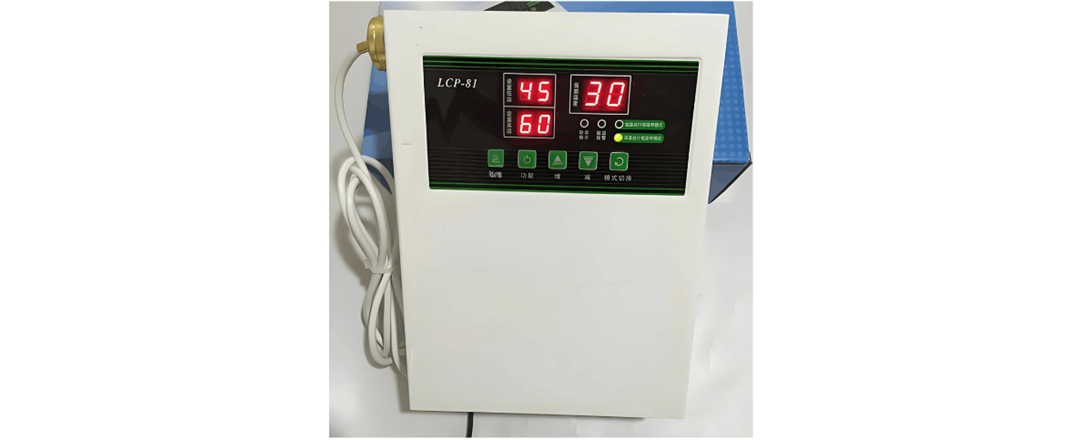

The temperature control module consists of a sensor and a temperature controller. Specifically, the sensor is installed on the heating tape of phase B of the porcelain post type circuit breaker. Its function is to measure the temperature at the transmission chamber of the porcelain post type circuit breaker and transmit the temperature data to the temperature controller, as shown in Figure 2. The temperature controller is a JY-260 microcomputer temperature controller. It is used to receive and display the temperature at this position, and control the start and stop of the heating module according to the preset temperature threshold, as depicted in Figure 3.

Figure 2 Temperature sensor

Figure 3 Thermostat

3.3 Power Module

The power module includes a temperature-controlled power supply and a forced-start power supply, as shown in Figure 4. Among them, the temperature-controlled power supply is connected to the heating module through the temperature controller. According to the ambient temperature in the Bashang area, the operating threshold of the temperature-controlled power supply is set, and the temperature-controlled power supply operates normally within this threshold. The forced-start power supply is directly connected to the heating module. When the temperature is lower than the operating threshold of the temperature-controlled power supply, the forced-start power supply is activated.

Figure 4 Temperature-controlled power supply

3.4 Working Modes of the Heating Device

The heating device of the porcelain post type SF₆ circuit breaker has two heating modes.

(1) Temperature control mode: The heating device uses the sensor installed on the heating tape of phase B of the porcelain post type circuit breaker to obtain the temperature at the transmission chamber of the porcelain post type circuit breaker and transmit it to the temperature controller. The temperature controller receives and displays the temperature of the heating tape of the porcelain post type circuit breaker, and then controls the heating module according to the preset temperature threshold.

(2) Forced start mode: By bypassing the temperature controller, continuous heating of the transmission chamber is carried out, and the SF₆ gas inside the porcelain post type circuit breaker is heated. In this way, problems such as low-pressure alarms of the porcelain post type circuit breaker and a decrease in the breaking capacity caused by the liquefied SF₆ gas can be avoided.

4 Conclusion

Aiming at the frequent occurrence of low-pressure alarms and even lockouts of circuit breakers in extremely cold weather in the Bashang area of Zhangjiakou, this paper designs a gas heating device for the 110kV porcelain post type SF₆ circuit breaker. This device can ensure the safe and stable operation of the circuit breaker. Moreover, it has the advantages of low installation cost and short installation time, and shows good promotion value.