What are the Types of Transformers Windings?

What are the Types of Transformers Windings?

Types of Transformers

Core type transformers have windings on outer limbs

Shell type transformers have windings on inner limbs

Mainly there are two types of transformer

Core type transformer

Shell type transformer

Types of Winding used for Core Type Transformer

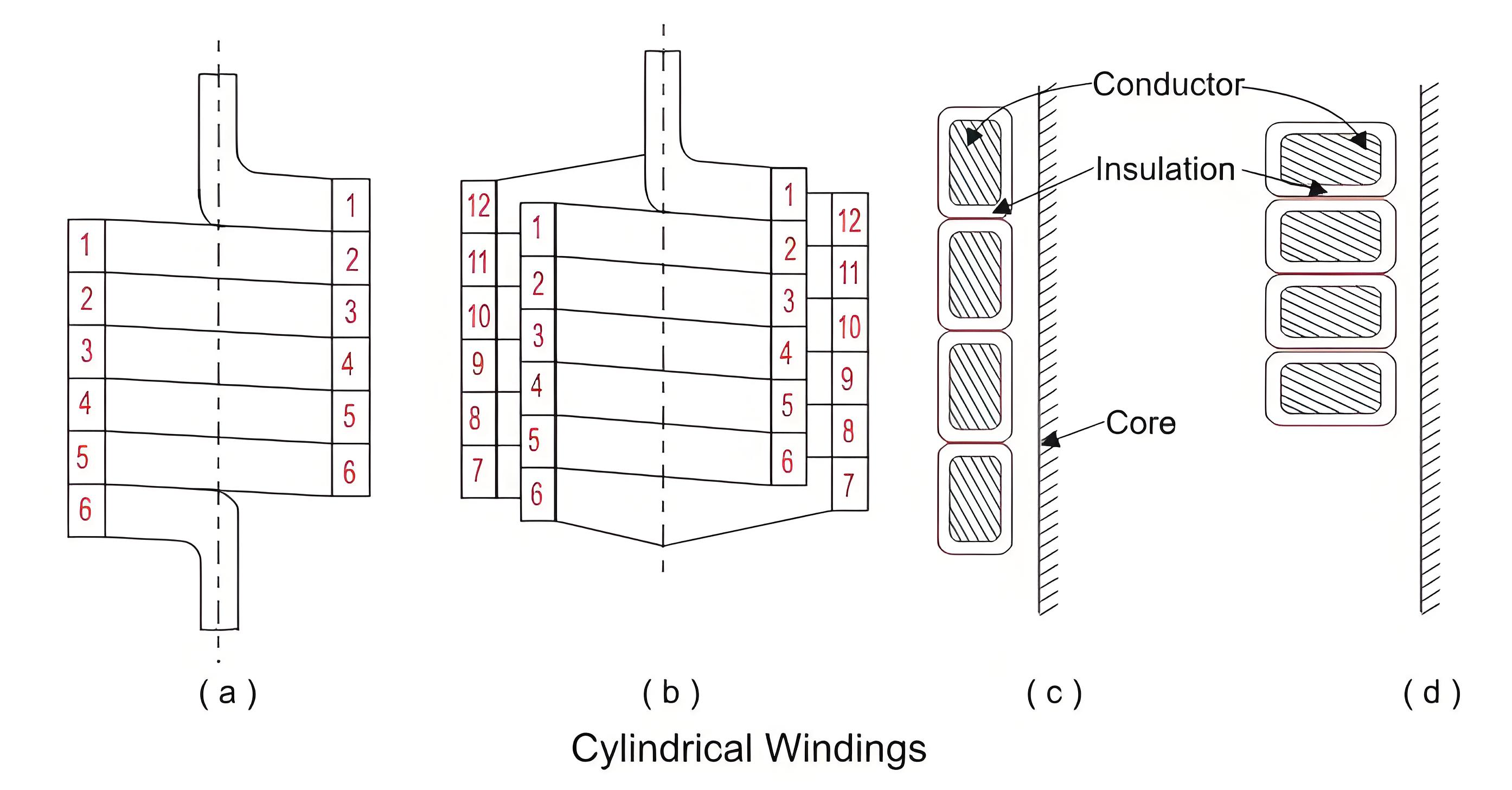

Cylindrical Windings

These windings are layered type and uses a rectangular or round conductor shown in Fig.(a) and (b). The conductors are wound on flat sides shown in Fig.(c) and wound on the rib side in Fig.(d).

Uses of Cylindrical Windings

Cylindrical windings are low voltage windings used up to 6.6 kV for kVA up to 600-750, and current rating between 10 to 600 A.

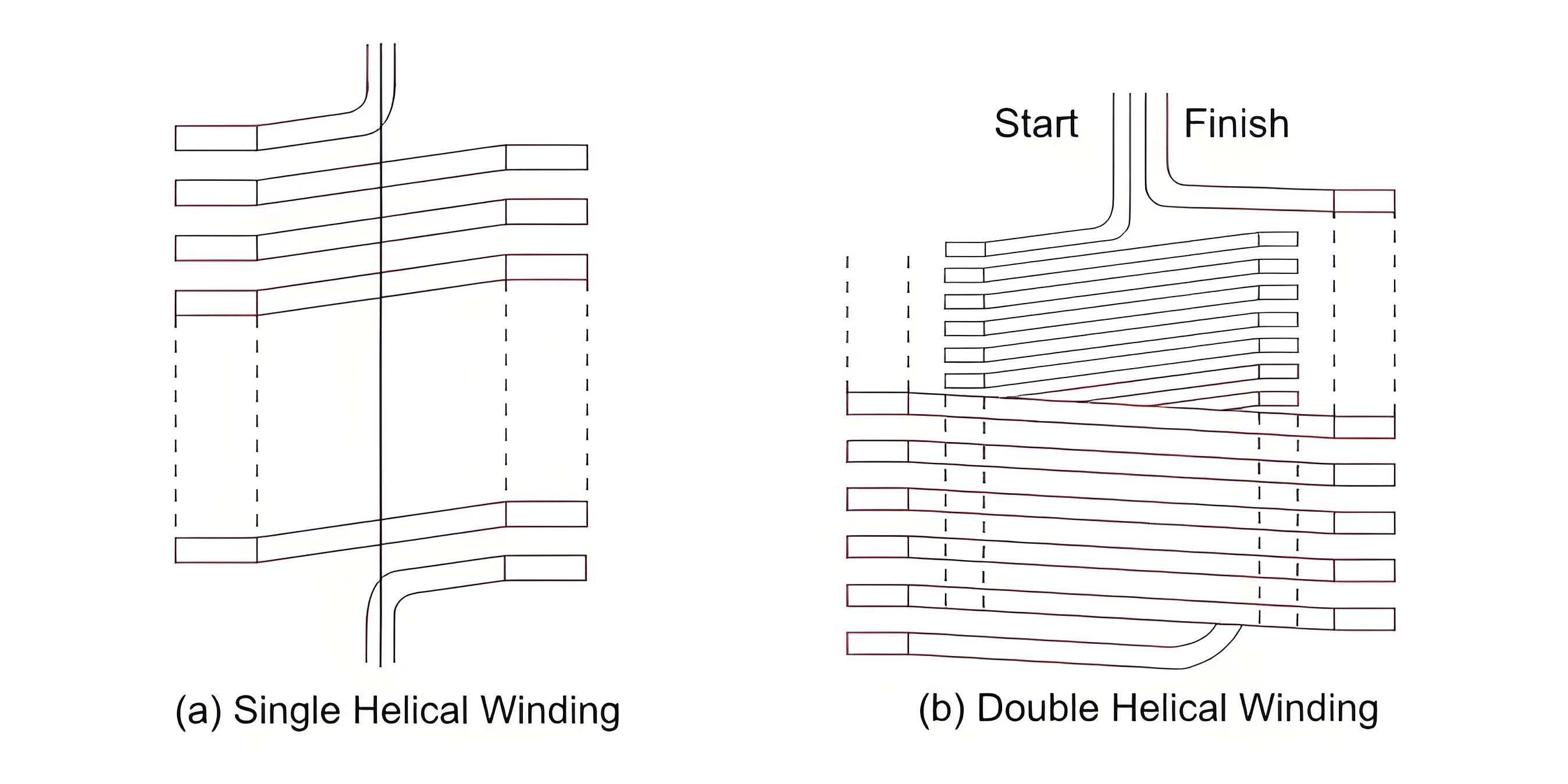

Helical Windings

We use helical windings low voltage, high capacity transformers, where the current is higher, at the same time windings turns are lesser. The output of the transformer varies from 160 – 1000 kVA from 0.23-15 kV. To secure adequate mechanical strength the cross-sectional area of the strip not made less than 75-100 mm square. The maximum number of strips used in parallel to make up a conductor is 16.

There are three types

Single Helical Winding

Double Helical Winding

Disc-Helical Winding

Single Helical Windings consist of winding in an axial direction along a screw line with an inclination. There is only one layer of turns in each winding. The advantage of Double Helical Winding is that it reduces eddy current loss in conductors. This is on account of the reduced number of parallel conductors situated in the radial direction.

In Disc-Helical Windings, parallel strips are placed side by side in a radial direction to cover the entire radial depth of the winding.

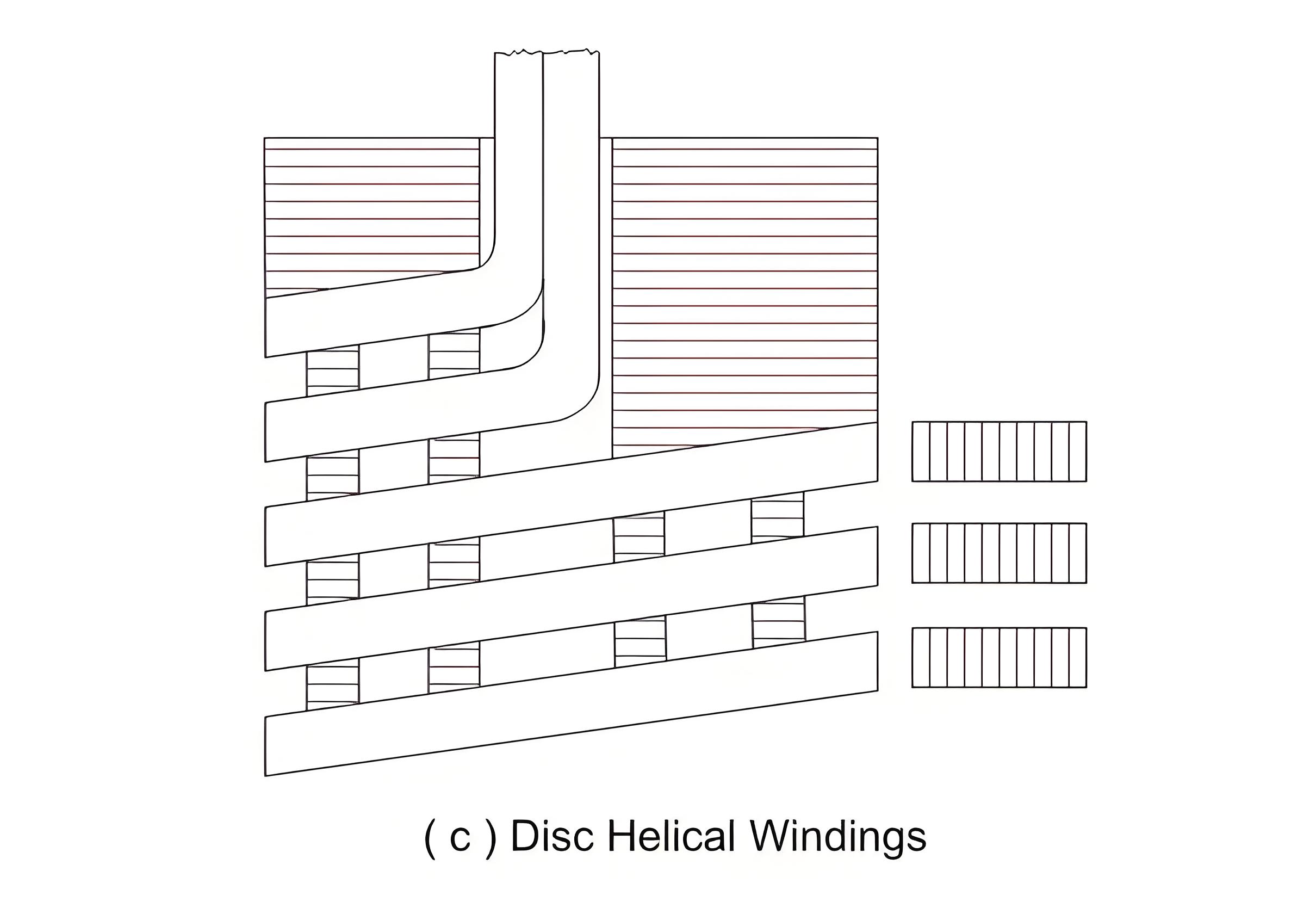

Multi-layer Helical Winding

We use it commonly for high voltage ratings for 110 kV and above. These types of winding consist of several cylindrical layers concentrically wound and connected in series.

We make the outer layers shorter than the inner layers to distribute capacitance uniformly. These windings primarily improve the surge behavior of transformers.

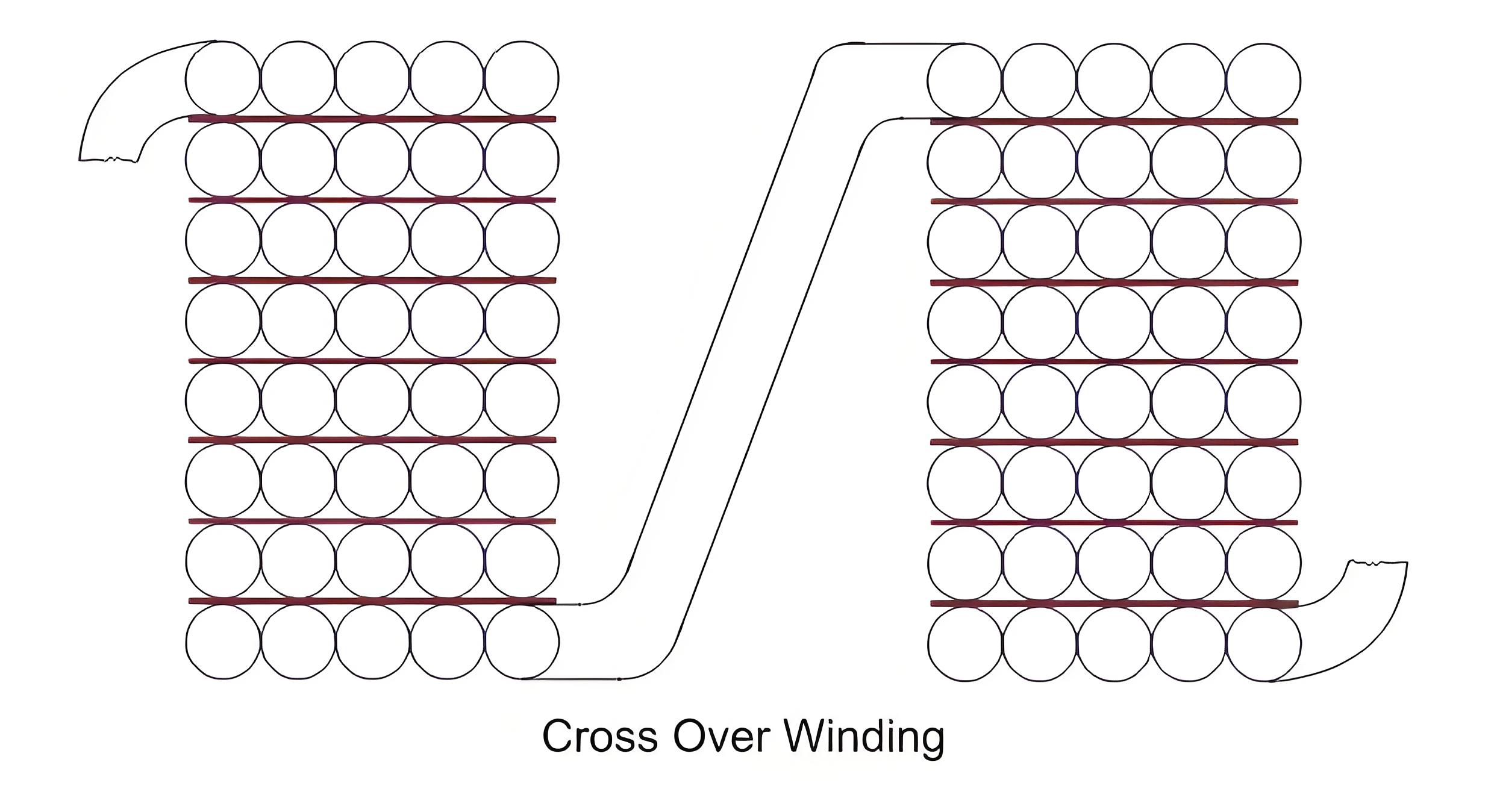

Crossover Winding

These windings are used in high voltage windings of small transformers. The conductors are paper-covered round wires or strips. The windings are divided into several coils to reduce voltage between adjacent layers. These coils are axially separated by 0.5 to 1 mm, with the voltage between adjacent coils kept within 800 to 1000 V.

The inside end of a coil is connected to the output side end of the adjacent one as shown in the above figure. The actual axial length of each coil is about 50 mm while the spacing between two coils is about 6 mm to accommodate blocks of insulating material.

The width of the coil is 25 to 50 mm. The crossover winding has a higher strength than cylindrical winding under normal conditions. However, the crossover has lover impulse strength than the cylindrical one. This type also has higher labor costs.

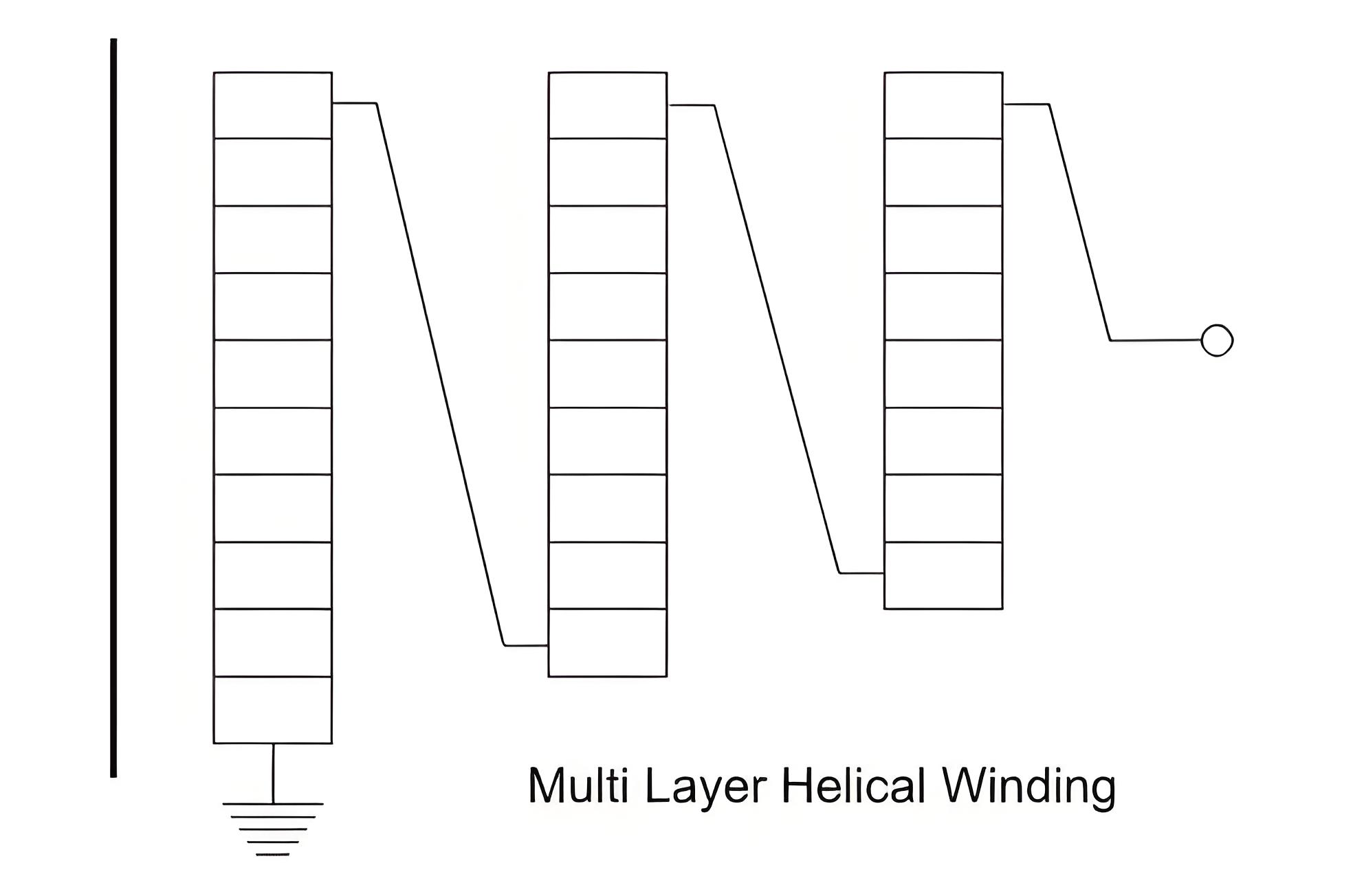

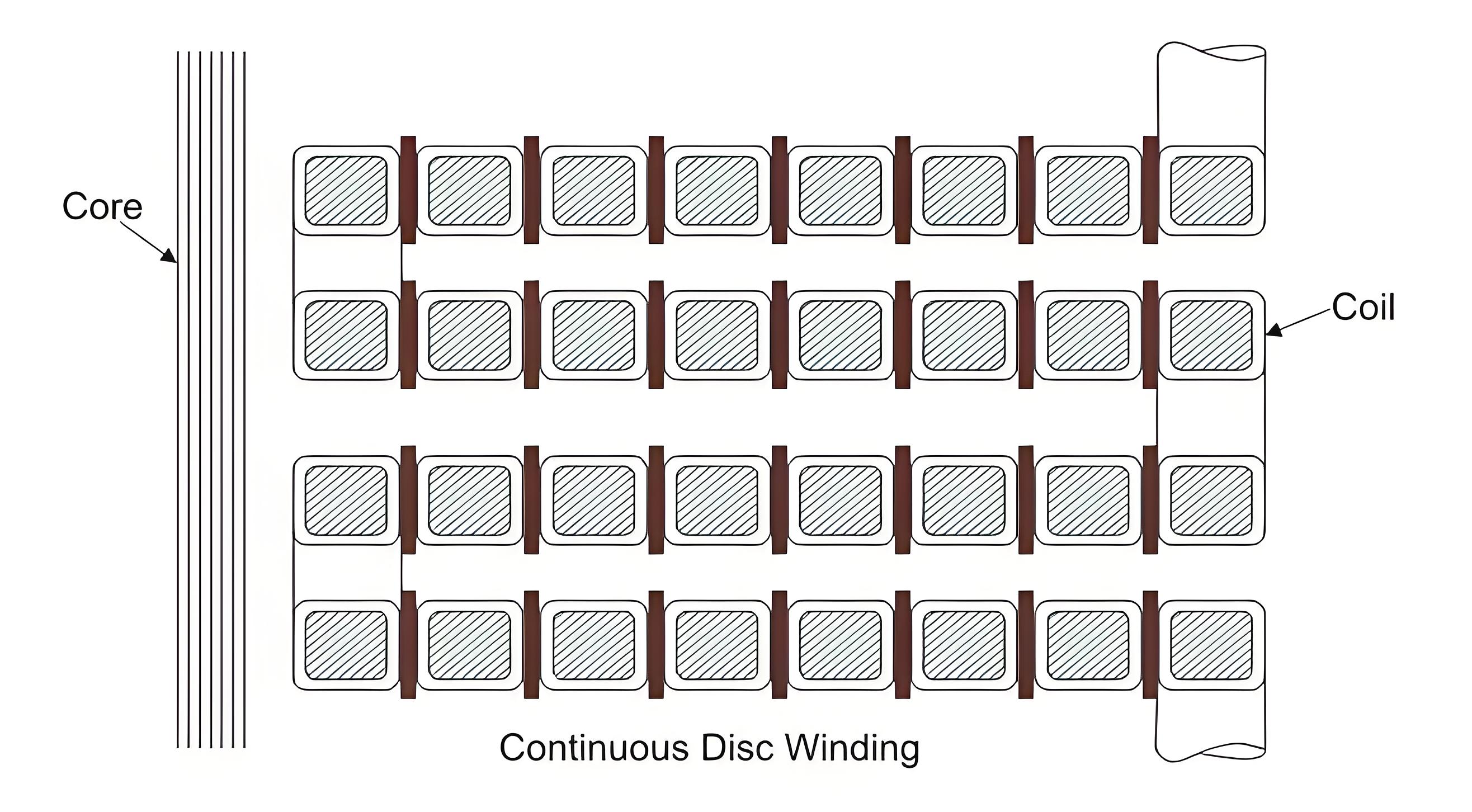

Disc and Continuous Disc Winding

Primarily used for a high capacity transformer. The winding consists of a number of flat coils or discs in series or parallel. The coils are formed with rectangular strips wound spirally from the center outwards in the radial direction as shown in the figure below.

The conductors can be a single strip or multiple strips in a parallel wound on the flat side. This makes robust construction for this type of windings. Discs are separated from each other with press-board sectors attached to vertical stripes.

The vertical and horizontal spacers provide radial and axial ducts for the free circulation of oil which comes in contact with every turn. The area of the conductor varies from 4 to 50 mm square and limits for current are 12 – 600 A. The minimum width of the oil duct is 6 mm for 35 kV. The advantage of the disc and continuous windings is their greater mechanical axial strength and cheapness.

Windings for Shell Type Transformer

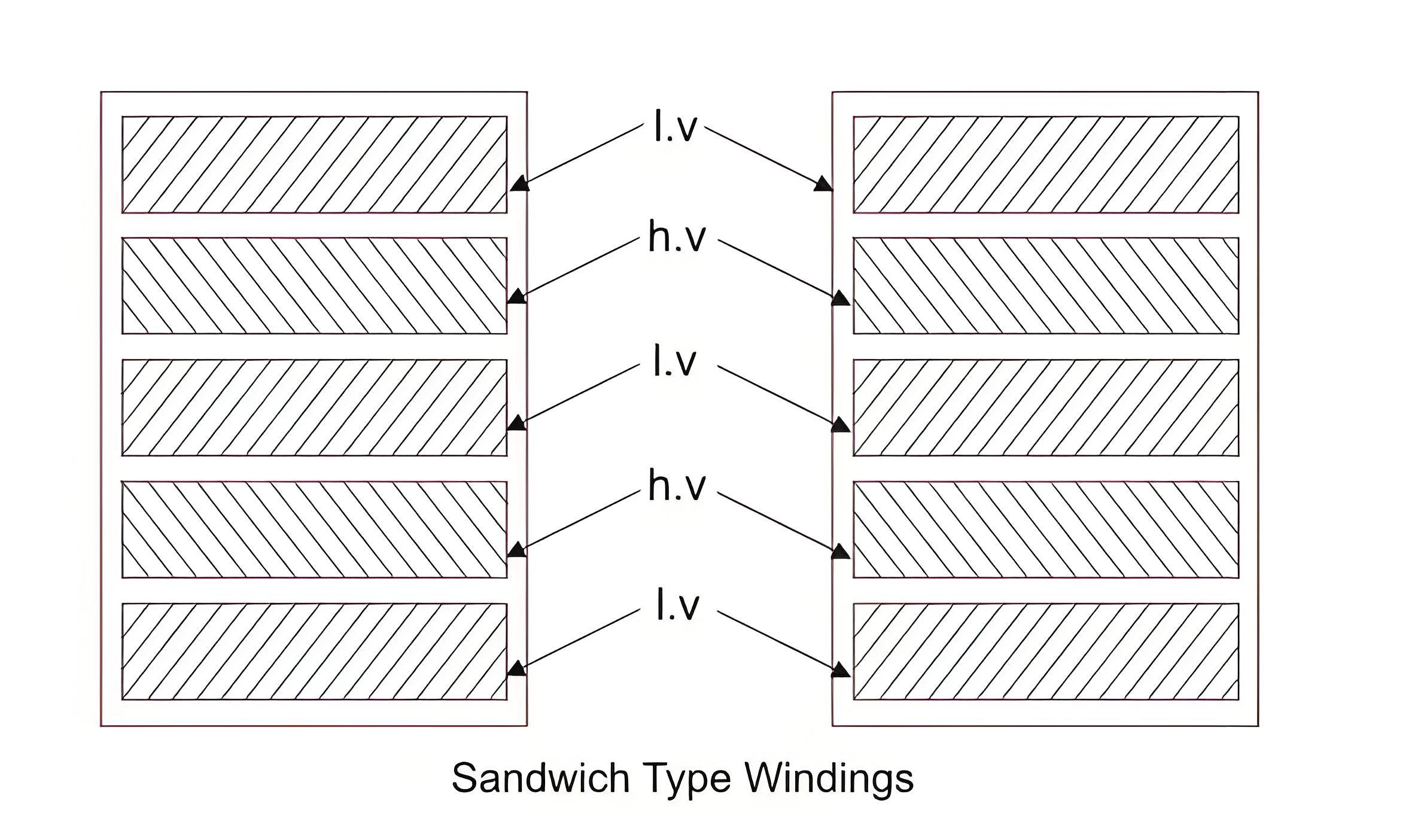

Sandwich Type Winding

Allow easy control over the reactance the nearer two coils are together on the same magnetic axis, the greater is the proportion of mutual flux and the less is the leakage flux.

Leakage can be reduced by subdividing the low and high voltage sections. The end low voltage sections, known as half coils, contain half the turns of the normal low voltage sections.

In order to balance the magnetomotive forces of adjacent sections, each normal section whether high or low voltage carries the same number of ampere-turns. The higher the degree of subdivision, the smaller is the reactance.

Advantages of Shell Type Windings in Transformers

High short-circuit withstand capability

High mechanical strength

High dielectric strength

Excellent control of leakage magnetic flux

Efficient cooling capability

Flexible design

Compact size

Highly Reliable Design

The Electricity Encyclopedia is dedicated to accelerating the dissemination and application of electricity knowledge and adding impetus to the development and innovation of the electricity industry.