Introduction of transformer dimensions based on IEC 60076

Relationship Between Rated Capacity and Dimensions

Definition of Rated Capacity: According to IEC 60076-1, the rated capacity is the maximum apparent power (kVA or MVA) allowed under continuous load, ensuring compliance with steady-state temperature rise and voltage regulation requirements.

Key Parameters Affecting Dimensions:

- No-load loss (P0) and load loss (Pk)directly influence the physical size of the core and windings.

- Short-circuit impedance (%) correlates with winding turns and insulation distances; higher impedance designs may require larger dimensions.

Winding Connection Types and Structural Design

- Y-Type Winding: Suitable for high-voltage sides, cost-effective, and supports neutral grounding. Commonly used in Dyn11 configurations to reduce zero-sequence impedance.

- D-Type Winding: Ideal for low-voltage, high-current scenarios. Combined with Y-type windings, it optimizes zero-sequence current paths (e.g., Yd11 or Dyn11 for 10/0.4kV distribution transformers).

Cooling Methods and Physical Dimensions

Cooling Types:

- AN (Natural Cooling): Relies on radiators for heat dissipation, compact but limited in capacity.

- AF (Forced Air Cooling): Requires fans, increases volume but supports higher capacities.

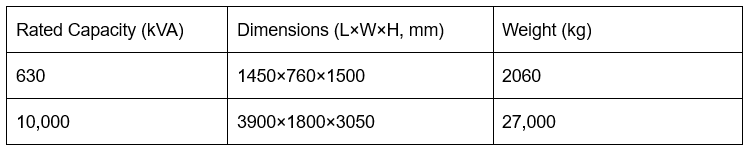

Example Dimensions (from technical specifications):

Insulation Levels and Dimensional Impact

- Insulation Classes:F-class or H-class insulation materials allow more compact designs due to higher temperature tolerance.

- Insulation Test Requirements:Impulse withstand voltages (e.g., LI75 AC35 for low-voltage side and LI170 AC70 for high-voltage side) affect winding spacing and insulation thickness.

Tap Range and Structural Complexity

Tap Changers: A ±2×2.5% tap range requires built-in voltage regulation windings, potentially increasing axial dimensions.

Summary

Transformer dimensions are determined by rated capacity, losses, cooling methods, and insulation requirements. Practical designs should follow IEC 60076-1 general rules and IEC 60076-8 load guidelines, combined with standardized parameter tables (e.g., ). Avoid oversimplified models like "optimal load rate," as emphasized in IEC standards.