What is Induction Motor Maintenance ?

What is Induction Motor Maintenance ?

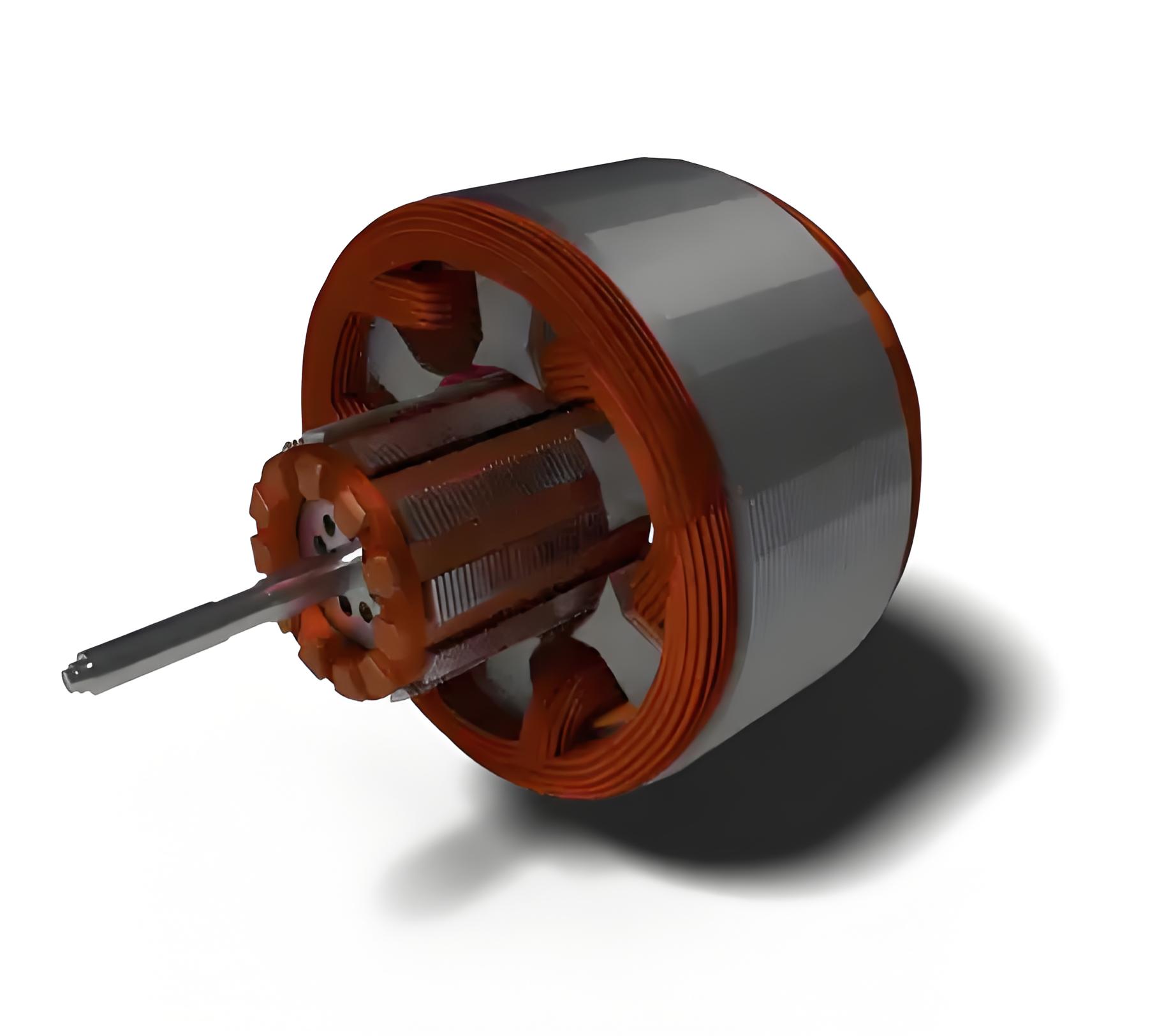

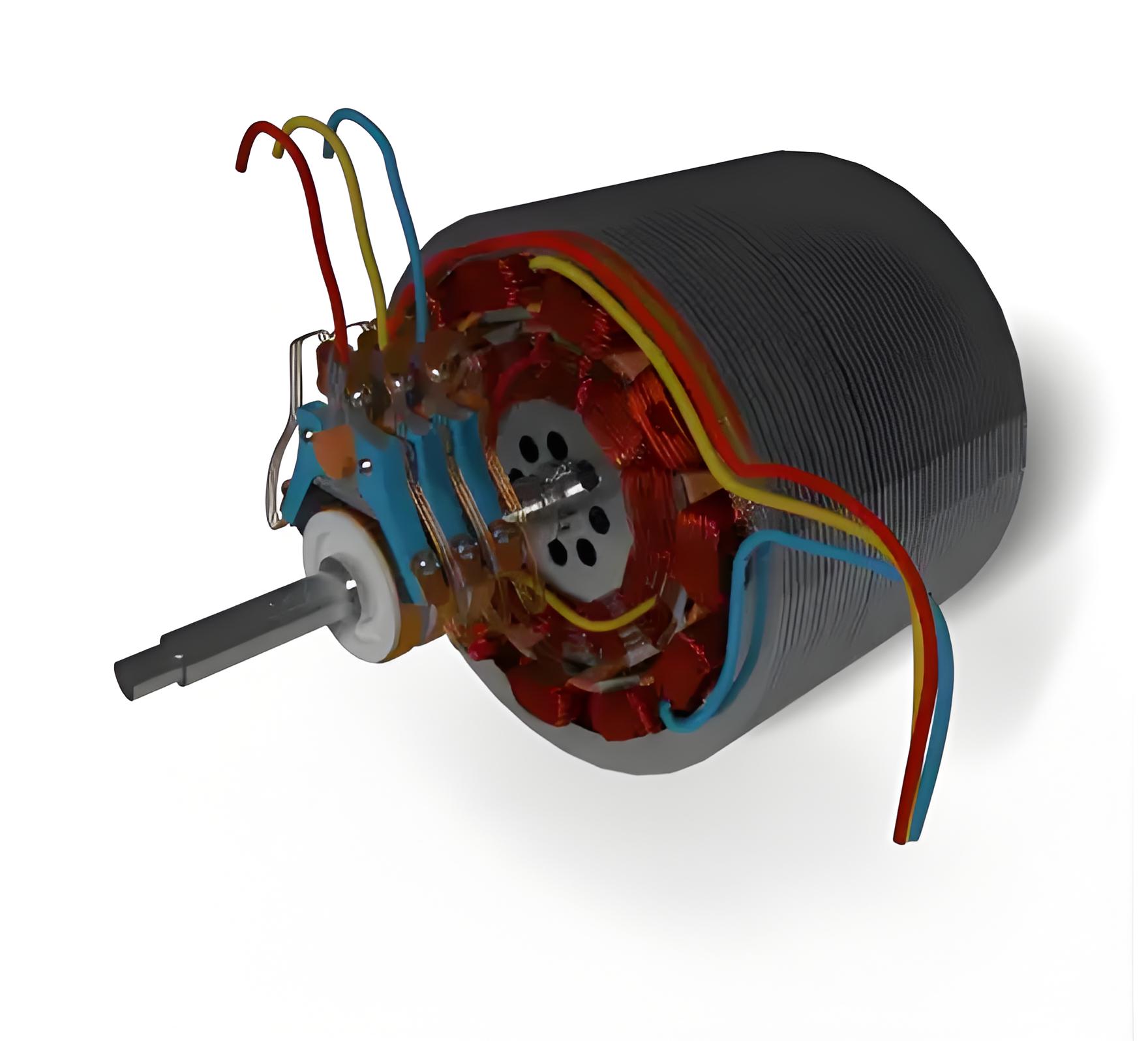

Induction motor maintenance definition

Induction motor maintenance involves operations that increase the life of the equipment and help it operate more efficiently.

Maintenance types of induction motors

Squirrel cage induction motors: Squirrel cage induction motors require much less maintenance because they do not contain brushes, commutators, or slip rings.

Coil rotor induction motor: Because it contains slip rings, brushes, so it does need to be maintained from time to time.

Maintenance type

Maintenance is divided into restorative (corrective)

This type of maintenance occurs after a failure occurs. It has the disadvantages of shortening the service life of the machine and wasting energy. It is also known as corrective maintenance.

Protective (preventive) type

This relates to planned measures taken to prevent breakdowns and failures. Examples include oil changes, lubrication, belt tightening, and filter changes.

Common fault

Stator winding fault

Bearing failure

Rotor fault

Maintenance schedule

Regular maintenance tasks should be performed weekly, every five/six months, and once a year to keep the motor in good condition.

Importance of maintenance

A proper maintenance schedule is essential to prevent costly repairs and ensure efficient operation, especially for three-phase induction motors.

The Electricity Encyclopedia is dedicated to accelerating the dissemination and application of electricity knowledge and adding impetus to the development and innovation of the electricity industry.